In simple terms, the coefficient of friction (COF) is a single number that quantifies the resistance between two surfaces as they slide against each other. This value typically ranges from near 0 for very slippery surfaces to over 1 for those with high grip. Understanding COF is fundamental to engineering because it directly predicts how a mechanical system will perform, how much energy it will consume, and how long its components will last.

The coefficient of friction is not just an abstract measurement; it is the key variable that dictates a system's efficiency, durability, and heat production. Mastering friction is about controlling this number to meet a specific engineering goal.

The Core Function of the Coefficient of Friction

The primary purpose of COF is to simplify a complex physical interaction into a single, practical value. This allows engineers and designers to predict and model system behavior without analyzing every microscopic detail of the interacting surfaces.

A Simple Analogy: Pushing a Box

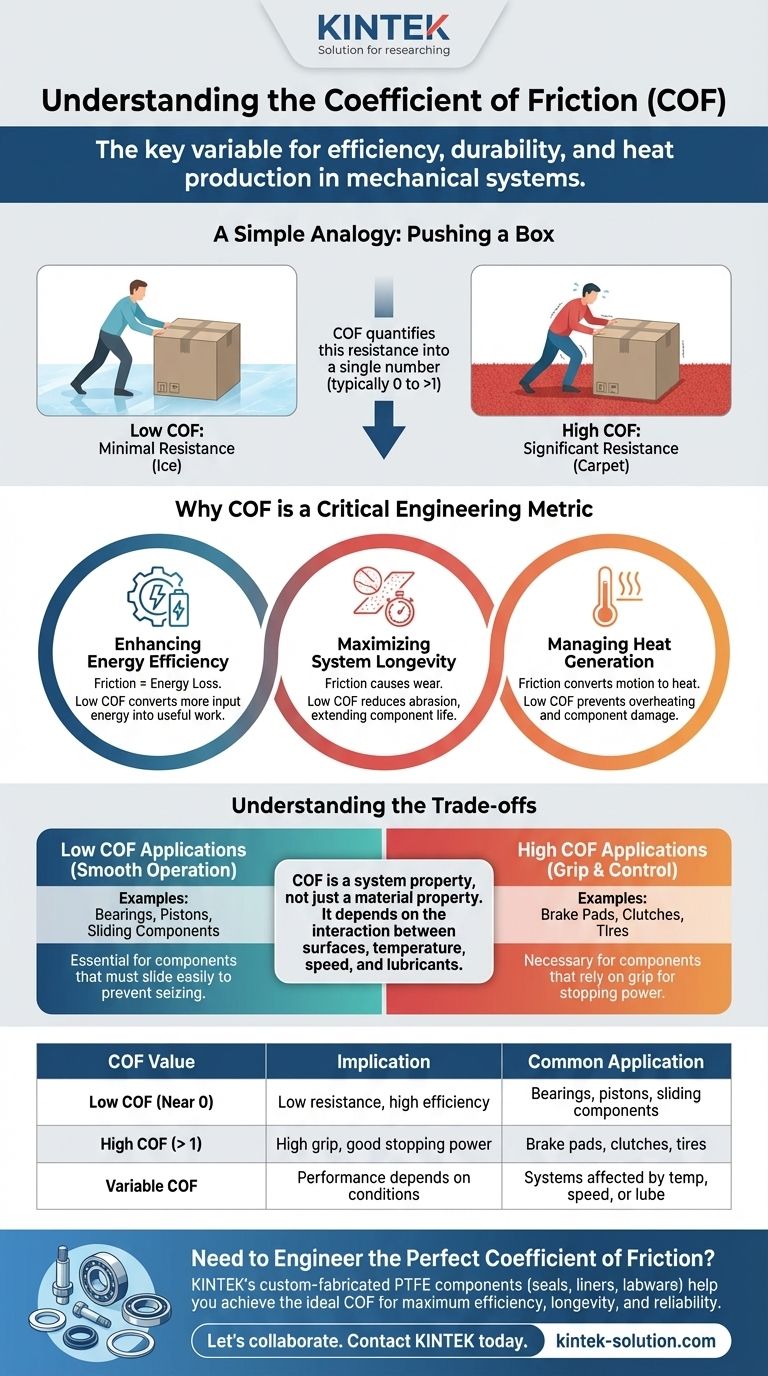

Imagine pushing a heavy box across two different floors. Pushing it across a smooth, icy surface is easy, while pushing it across a thick carpet is difficult. The coefficient of friction gives us a number to describe that difference.

The ice has a low COF, meaning there is very little resistance. The carpet has a high COF, indicating significant resistance that you must overcome.

Quantifying Mechanical Resistance

In engineering, this simple concept is critical. A low COF is essential for components that must slide easily, like bearings or pistons. It ensures smooth operation and prevents parts from seizing up.

Conversely, a high COF is necessary for components that rely on grip, such as brake pads, clutches, or the tires on a vehicle.

Why COF is a Critical Engineering Metric

Controlling the coefficient of friction is essential for achieving three primary goals in any mechanical system: efficiency, longevity, and thermal stability.

Enhancing Energy Efficiency

Friction is a direct source of energy loss. A high COF means more energy must be expended to overcome resistance, and this wasted energy is almost always converted into heat.

By designing for a low COF, you ensure that more of the input energy is converted into useful work, dramatically improving the overall efficiency of the machine.

Maximizing System Longevity

Friction causes wear. As two surfaces slide against each other, the resistance between them slowly abrades material, leading to component degradation and eventual failure.

A lower COF directly translates to less wear and tear. This extends the operational life of parts, reduces maintenance requirements, and increases the reliability of the entire system.

Managing Heat Generation

Unwanted heat is a major challenge in mechanical design. Since friction converts motion into thermal energy, a high COF can lead to a rapid increase in temperature.

Controlling the COF is a primary strategy for thermal management. Keeping it low prevents overheating, which can damage components, degrade lubricants, and cause system failure.

Understanding the Trade-offs

While it is often desirable to minimize friction, this is not a universal rule. The ideal COF is entirely dependent on the specific application.

Friction is Not Always the Enemy

The ability to walk, drive a car, or pick up an object relies on friction. In systems like vehicle brakes or industrial clutches, a high and stable coefficient of friction is the primary design goal.

The objective is not always to achieve the lowest possible COF, but to engineer the correct and predictable COF for the task.

It's a System Property

A common misconception is that COF is a property of a single material. In reality, it is a property of the interaction between two surfaces.

The COF between steel and bronze, for example, is different from the COF between steel and polymer. Factors like surface roughness, temperature, sliding speed, and the presence of lubricants all influence the final value.

Making the Right Choice for Your Goal

Your approach to the coefficient of friction should be dictated by your primary engineering objective.

- If your primary focus is energy efficiency: Your goal is to minimize the COF between all moving parts through material selection and proper lubrication.

- If your primary focus is durability: Selecting materials and coatings for a low COF is the most direct way to reduce wear and extend the service life of your components.

- If your primary focus is control or stopping power: You must design for a high, stable COF that performs reliably under operational stress, such as in braking systems.

Ultimately, understanding the coefficient of friction empowers you to move beyond fighting resistance and begin designing it with purpose.

Summary Table:

| COF Value | Implication | Common Application |

|---|---|---|

| Low COF (Near 0) | Low resistance, high efficiency | Bearings, pistons, sliding components |

| High COF (> 1) | High grip, good stopping power | Brake pads, clutches, tires |

| Variable COF | Performance depends on conditions | Systems affected by temperature, speed, or lubrication |

Need to Engineer the Perfect Coefficient of Friction for Your Application?

At KINTEK, we understand that controlling friction is key to your product's performance. Whether you're in the semiconductor, medical, laboratory, or industrial sector, our custom-fabricated PTFE components (seals, liners, labware, and more) are engineered for precision and durability. We can help you achieve the ideal COF to maximize efficiency, extend component life, and ensure reliable operation.

Let's collaborate to solve your friction challenges. Contact our engineering team today to discuss your project—from prototypes to high-volume production.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments