To ensure the longevity and optimal performance of Polytetrafluoroethylene (PTFE), you must adopt a strategy centered on preservation rather than active repair. The best practices involve cleaning with mild detergents, conducting regular visual inspections for wear, storing components in controlled environments, and handling them carefully to prevent surface damage from the outset.

Optimal PTFE performance is less about intensive, active maintenance and more about establishing a controlled environment. Protecting the material's inherent low-friction surface and operating within its physical limits are the most critical factors for long-term reliability.

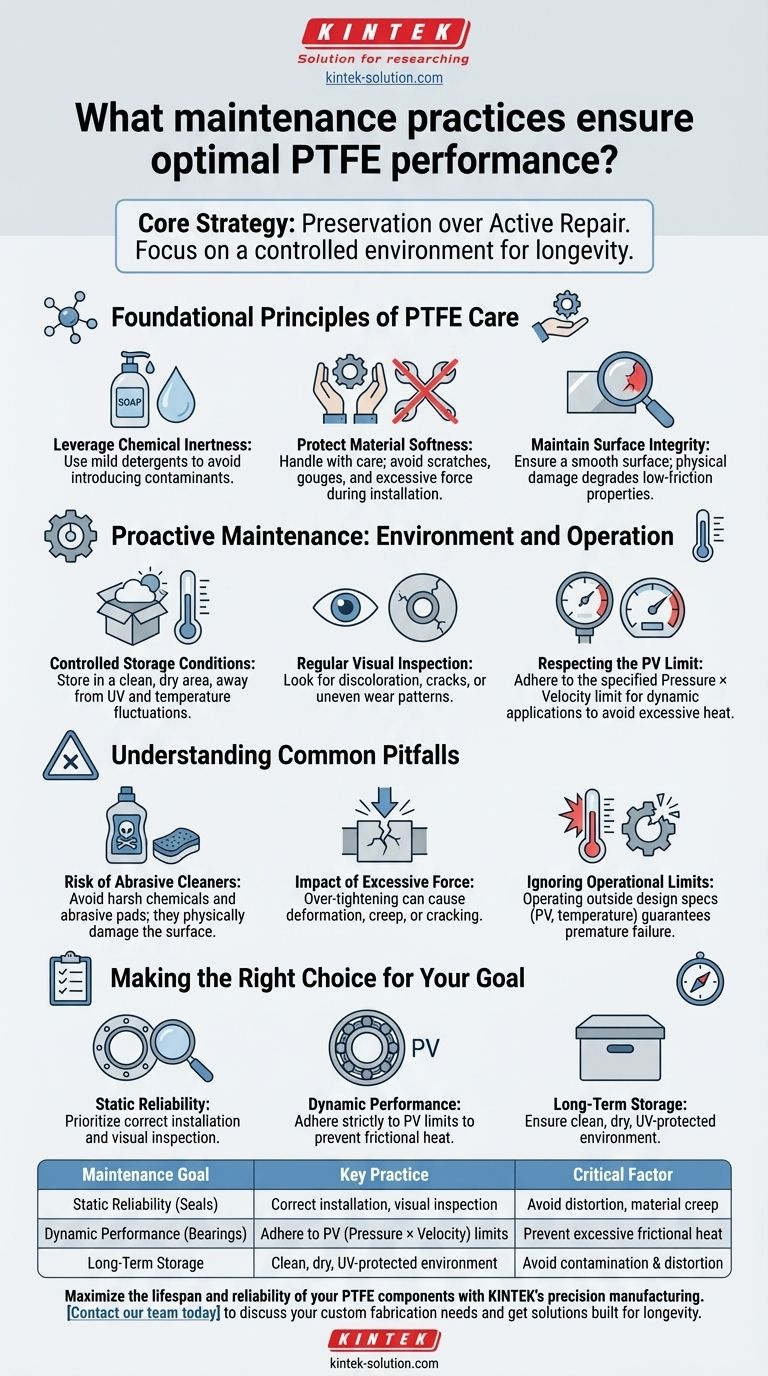

Foundational Principles of PTFE Care

Understanding the core properties of PTFE is essential to maintaining it effectively. The material's unique characteristics dictate the best practices for its care and handling.

Leveraging Chemical Inertness

PTFE is renowned for its outstanding resistance to almost all chemicals.

Because of this, the goal of cleaning is not to protect the PTFE from the cleaner, but to avoid introducing contaminants or abrasives. Using mild detergents ensures the surface is free of debris that could increase friction or cause scoring.

Protecting Material Softness

A key characteristic of PTFE is its softness and formability. This makes it an excellent material for seals but also renders it susceptible to physical damage.

Careful handling is paramount, especially during installation. Scratches, gouges, or distortion from excessive clamping pressure can create failure points and compromise the material's performance.

Maintaining Surface Integrity

The defining feature of PTFE is its extremely low coefficient of friction. This property is entirely dependent on a smooth, uninterrupted surface.

Any physical damage, from a minor scratch to abrasive wear, will permanently degrade its low-friction performance and accelerate material failure.

Proactive Maintenance: Environment and Operation

The most effective maintenance strategy for PTFE is proactive. By controlling the component's environment and operational load, you prevent the root causes of degradation.

Controlled Storage Conditions

Proper storage is the first step in ensuring component readiness and lifespan.

Store PTFE parts in a clean, dry area away from direct sunlight (UV radiation) and extreme temperature fluctuations. This prevents contamination and physical distortion before the component is ever placed into service.

Regular Visual Inspection

Periodic inspection is a simple yet effective way to preempt failure.

Look for signs of stress like discoloration, cracks, or uneven wear patterns. These symptoms often indicate that the component is operating outside its designed limits or that an external factor is causing premature degradation.

Respecting the PV Limit

For dynamic applications like bearings or slide plates, the PV value (Pressure × Velocity) is the most critical operational parameter.

Every PTFE grade has a maximum PV limit specified by the manufacturer. Exceeding this value generates excessive frictional heat, leading to rapid wear and premature failure. Staying within this limit is a form of proactive maintenance.

Understanding Common Pitfalls

Avoiding common mistakes is as important as following best practices. Certain actions can irreversibly damage PTFE components.

The Risk of Abrasive Cleaners

Never use harsh chemicals, solvents not rated for PTFE, or abrasive scouring pads for cleaning.

While the material is chemically resistant, these agents can physically damage the surface, destroying its low-friction properties and creating sites for accelerated wear.

The Impact of Excessive Force

The material's softness means it cannot withstand excessive force during installation or operation.

Over-tightening fittings or applying high clamping pressure can cause the material to deform, creep, or crack, leading to immediate leaks or mechanical failure.

Ignoring Operational Limits

The most common cause of premature PTFE failure is operating outside of its design specifications.

Running a component above its rated PV value or temperature limit is a guarantee of failure, regardless of how well it is cleaned or stored.

Making the Right Choice for Your Goal

To maximize the service life of your PTFE components, align your maintenance strategy with your primary operational goal.

- If your primary focus is reliability in a static environment (e.g., seals, gaskets): Prioritize correct installation without distortion and regular inspection for discoloration or material creep.

- If your primary focus is performance in a dynamic application (e.g., bearings, bushings): Adhering to the manufacturer's specified PV (Pressure × Velocity) value is the single most critical factor.

- If your primary focus is long-term storage and readiness: Ensure components are kept in a clean, dry location away from direct sunlight and extreme temperature fluctuations.

Ultimately, preserving the inherent properties of PTFE through careful handling and controlled operation is the most effective maintenance strategy.

Summary Table:

| Maintenance Goal | Key Practice | Critical Factor |

|---|---|---|

| Static Reliability (Seals, Gaskets) | Correct installation, visual inspection | Avoid distortion, material creep |

| Dynamic Performance (Bearings, Bushings) | Adhere to PV (Pressure × Velocity) limits | Prevent excessive frictional heat |

| Long-Term Storage | Clean, dry, UV-protected environment | Avoid contamination and distortion |

Maximize the lifespan and reliability of your PTFE components with KINTEK's precision manufacturing. Whether you need custom PTFE seals, liners, or labware for semiconductor, medical, or industrial applications, our expertise ensures components that perform under demanding conditions. Contact our team today to discuss your custom fabrication needs—from prototypes to high-volume orders—and get solutions built for longevity.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments