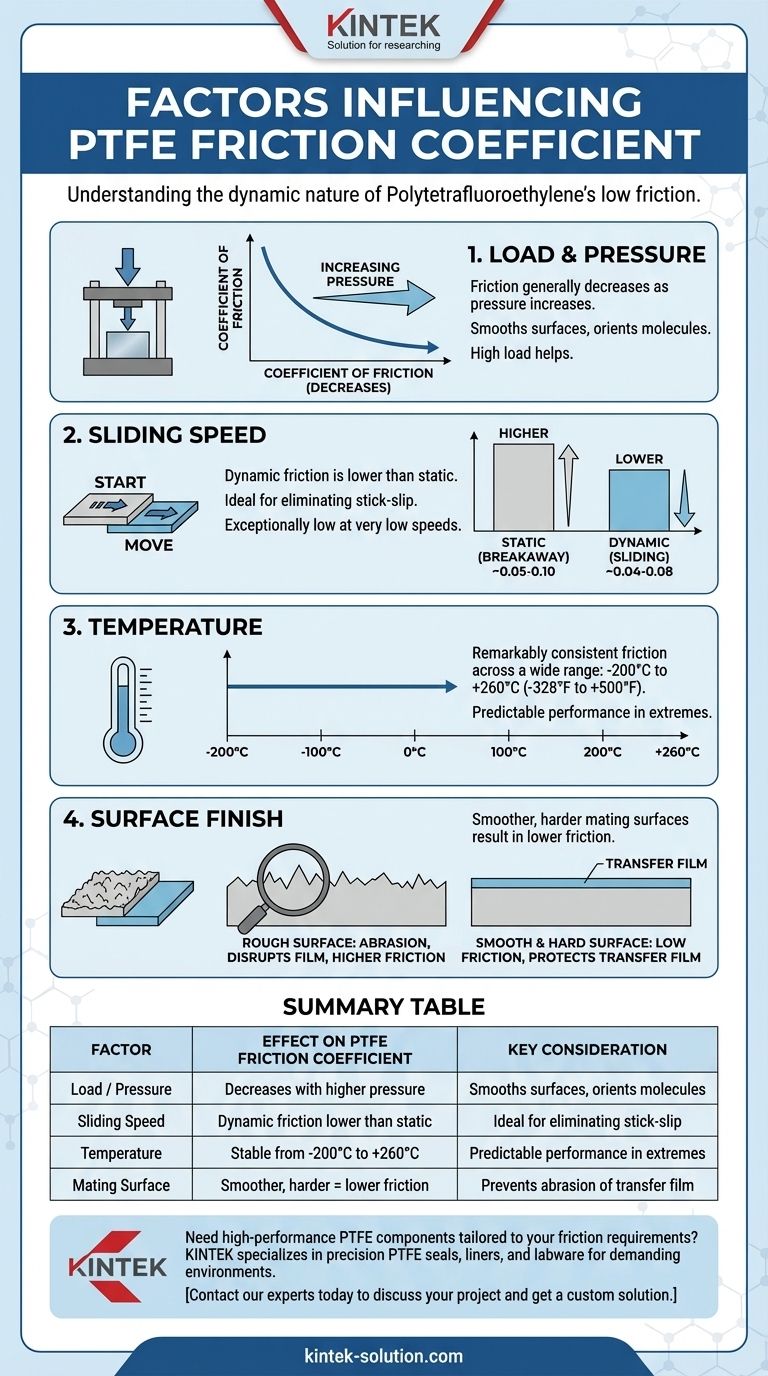

In short, the coefficient of friction in Polytetrafluoroethylene (PTFE) is not a fixed value. It is primarily influenced by the applied pressure (load), sliding velocity, temperature, and the roughness of the mating surface. Generally, higher pressures and lower speeds result in a lower coefficient of friction.

While often cited with a single friction value, PTFE's true performance is dynamic. Understanding how its friction coefficient changes with specific operating conditions is the key to designing reliable, low-friction systems.

The Source of PTFE's "Slipperiness"

Before examining the variables, it's crucial to understand why PTFE has such low friction. Its unique properties stem from its molecular structure.

A Molecule Designed for Low Friction

The fluorine atoms in the PTFE molecule form a tight, uniform sheath around the carbon backbone. This sheath is very stable and has extremely weak intermolecular attraction, known as van der Waals forces.

Because of this, other surfaces have almost nothing to "grab onto," resulting in one of the lowest coefficients of friction of any known solid. It is the only known surface a gecko cannot stick to.

Key Factors Influencing PTFE's Friction

The commonly cited friction coefficient for PTFE—often between 0.05 and 0.10—is merely a baseline. In any real-world application, this value will shift based on the following factors.

The Effect of Load and Pressure

Unlike many materials, PTFE's coefficient of friction generally decreases as pressure increases. Applying a higher load helps to smooth the surfaces and orient the PTFE molecules for easier sliding.

This effect continues up to a certain pressure limit, after which the material may begin to deform or creep.

The Impact of Sliding Speed

Speed significantly affects the friction, particularly when differentiating between starting and moving.

PTFE has a lower dynamic (sliding) friction than static (breakaway) friction. Its static coefficient of friction is typically in the range of 0.05 to 0.10, while its dynamic coefficient can be as low as 0.04 to 0.08.

At very low speeds (under 10 ft/min), friction is exceptionally low. As speed increases, the coefficient may rise slightly before stabilizing.

The Influence of Temperature

One of PTFE's greatest strengths is its thermal stability. Its friction coefficient remains remarkably consistent across a very wide operating temperature range, typically from -200°C to +260°C (-328°F to +500°F).

This makes it a predictable choice for applications involving extreme temperatures.

The Importance of Surface Finish

The nature of the surface sliding against the PTFE is critical. Smoother, harder mating surfaces result in a lower coefficient of friction.

A rougher surface can cause abrasion and disrupt the thin film of PTFE that transfers to the mating surface, increasing friction and wear.

Understanding the Practical Implications

Simply knowing the factors is not enough; you must understand how they interact and what they mean for your design.

Self-Lubrication is a Transfer Film

PTFE's "self-lubricating" property works by transferring an ultra-thin layer of its own material onto the mating surface. It is this PTFE-on-PTFE sliding that creates the low-friction interface.

If this film is scraped away by an abrasive surface or high-speed contact, friction can increase. In some abrasive environments, an external lubricant can help protect this film.

Design Adjustments for Low Friction

The exceptionally low friction of PTFE is a feature that often requires specific design considerations.

For example, in bolted joints using PTFE-coated fasteners, the standard torque-to-tension relationship is no longer valid. To achieve the required clamping force, tightening torque specifications must be significantly adjusted downward to prevent over-tightening and potential bolt failure.

Making the Right Choice for Your Goal

Use these principles to guide your design decisions when working with PTFE.

- If your primary focus is a low-friction bearing: Use a smooth, hard shaft and apply sufficient load to take advantage of the pressure-friction relationship.

- If your primary focus is eliminating stick-slip: Recognize that PTFE's static friction is slightly higher than its dynamic friction, but the difference is small, making it excellent for smooth startup.

- If your primary focus is predictable fastening: You must calculate or test new torque values for any PTFE-coated components to ensure correct pre-load.

By moving beyond a single textbook value, you can engineer solutions that fully leverage PTFE's remarkable low-friction properties.

Summary Table:

| Factor | Effect on PTFE Friction Coefficient | Key Consideration |

|---|---|---|

| Load / Pressure | Decreases with higher pressure | Smooths surfaces, orients molecules |

| Sliding Speed | Dynamic friction lower than static | Ideal for eliminating stick-slip |

| Temperature | Stable from -200°C to +260°C | Predictable performance in extremes |

| Mating Surface | Smoother, harder = lower friction | Prevents abrasion of transfer film |

Need high-performance PTFE components tailored to your specific friction requirements?

At KINTEK, we specialize in manufacturing precision PTFE seals, liners, and labware for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures your components are optimized for load, speed, and temperature, delivering reliable, low-friction performance in even the most demanding environments.

Contact our experts today to discuss your project and get a custom solution that maximizes PTFE's potential.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability