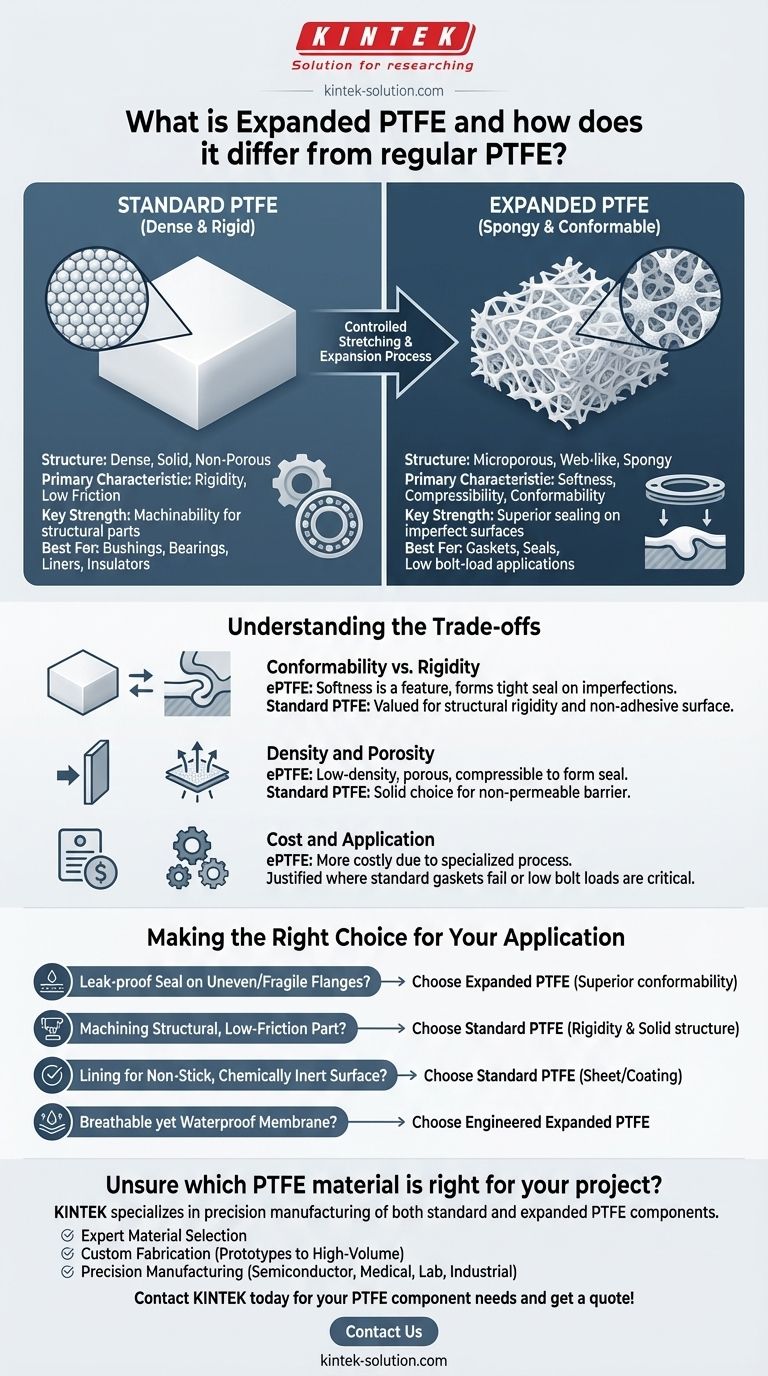

Expanded PTFE is standard PTFE that has been physically stretched to create a strong, yet soft and flexible, microporous material. The fundamental difference is structural: while standard PTFE is a dense, rigid solid, Expanded PTFE (ePTFE) has a spongy, web-like internal structure. This new structure gives it exceptional compressibility, allowing it to conform and seal imperfect surfaces where standard PTFE would fail.

While both materials share the same exceptional chemical and thermal resistance, the choice between them comes down to a single question: do you need a rigid, low-friction component or a soft, conformable sealant? Standard PTFE provides rigidity, while Expanded PTFE provides conformability.

The Foundation: Understanding Standard PTFE

A Material of Extremes

Standard Polytetrafluoroethylene (PTFE) is a fluoropolymer renowned for its remarkable set of properties. It is one of the most chemically inert substances known, resisting nearly all industrial chemicals, acids, and solvents.

It also boasts an incredibly wide operating temperature range, typically from -200°C to +260°C (-328°F to +500°F). Combined with its extremely low coefficient of friction—the lowest of any solid material—and excellent electrical insulation, it is a uniquely versatile material.

A Solid, Dense Structure

At a physical level, standard PTFE is a dense, non-porous, and relatively rigid plastic. Think of it as a solid block of material. This makes it ideal for machining into stable, structural parts like bushings, bearings, insulators, or liners where its low friction and inertness are paramount.

The Innovation: How "Expanded" PTFE is Different

The Manufacturing Process: From Solid to Spongy

Expanded PTFE begins as standard PTFE. Through a specialized process of controlled stretching, the material is pulled apart. This action transforms its dense molecular structure into a microscopic web of interconnected nodes and fibrils.

This new formation is mostly air, yet it retains the full chemical and thermal integrity of the original PTFE. The result is a material that is both strong and incredibly soft.

The Core Benefit: Compressibility and Conformity

This web-like structure is the key to ePTFE's primary advantage: compressibility. When pressure is applied, as in a bolted flange, the microporous structure can easily collapse.

This allows the ePTFE gasket or tape to flow into and fill imperfections, scratches, and misalignments on a surface. It creates an extremely tight, durable seal with much lower bolt force than required for solid materials, protecting fragile or glass-lined flanges.

Enhanced Mechanical Strength

The expansion process orients the material's fibrils, creating exceptional tensile strength. This makes ePTFE highly resistant to "creep" or "cold flow"—the tendency of standard PTFE to deform over time under constant pressure. This stability ensures a long-lasting, reliable seal that won't loosen.

Understanding the Trade-offs

Conformability vs. Rigidity

This is the central trade-off. ePTFE is engineered for sealing and gasketing applications where it must conform to a surface. Its softness is a feature, not a flaw.

Standard PTFE is valued for its rigidity and non-adhesive surface. You would machine a bearing from standard PTFE, but you would seal the housing with an ePTFE gasket.

Density and Porosity

By its nature, ePTFE is a low-density, porous material. In gasketing, this porosity is eliminated upon compression to create the seal. However, for applications requiring a non-permeable barrier without compression, solid PTFE is the correct choice.

Conversely, this porosity can be engineered into a feature, as seen in breathable waterproof fabrics like Gore-Tex, which is a well-known form of ePTFE membrane.

Cost and Application

The specialized manufacturing process makes ePTFE more costly than its standard counterpart. Its use is justified where standard gaskets fail or where low bolt loads and surface conformity are critical engineering requirements.

Making the Right Choice for Your Application

Ultimately, the material you choose depends entirely on the mechanical function it must perform.

- If your primary focus is creating a leak-proof seal on uneven, worn, or fragile flanges: Choose Expanded PTFE for its superior conformability and low compressive load.

- If your primary focus is machining a structural, low-friction part like a bearing, bushing, or insulator: Choose standard PTFE for its rigidity and solid structure.

- If your primary focus is lining a vessel or chute for a non-stick, chemically inert surface: Choose standard PTFE sheet or coating.

- If your primary focus is creating a breathable yet waterproof membrane for venting or apparel: Choose a specially engineered form of Expanded PTFE.

By understanding the fundamental structural difference between dense PTFE and microporous ePTFE, you can confidently select the material that delivers the precise performance your application demands.

Summary Table:

| Property | Standard PTFE | Expanded PTFE (ePTFE) |

|---|---|---|

| Structure | Dense, solid, non-porous | Microporous, web-like, spongy |

| Primary Characteristic | Rigidity, low friction | Softness, compressibility, conformability |

| Key Strength | Machinability for structural parts | Superior sealing on imperfect surfaces |

| Best For | Bushings, bearings, liners, insulators | Gaskets, seals, low bolt-load applications |

Unsure which PTFE material is right for your project?

KINTEK specializes in the precision manufacturing of both standard and expanded PTFE components. Whether you need rigid, machined parts or soft, conformable seals, our experts can help you select the ideal material and fabrication process for your specific requirements in the semiconductor, medical, laboratory, and industrial sectors.

We offer:

- Expert Material Selection: Get guidance on whether standard PTFE or ePTFE is best for your application's performance, temperature, and chemical resistance needs.

- Custom Fabrication: From prototypes to high-volume production, we create custom PTFE seals, liners, labware, and more to your exact specifications.

- Precision Manufacturing: Rely on our commitment to quality and precision in every component we produce.

Contact KINTEK today to discuss your PTFE component needs and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability