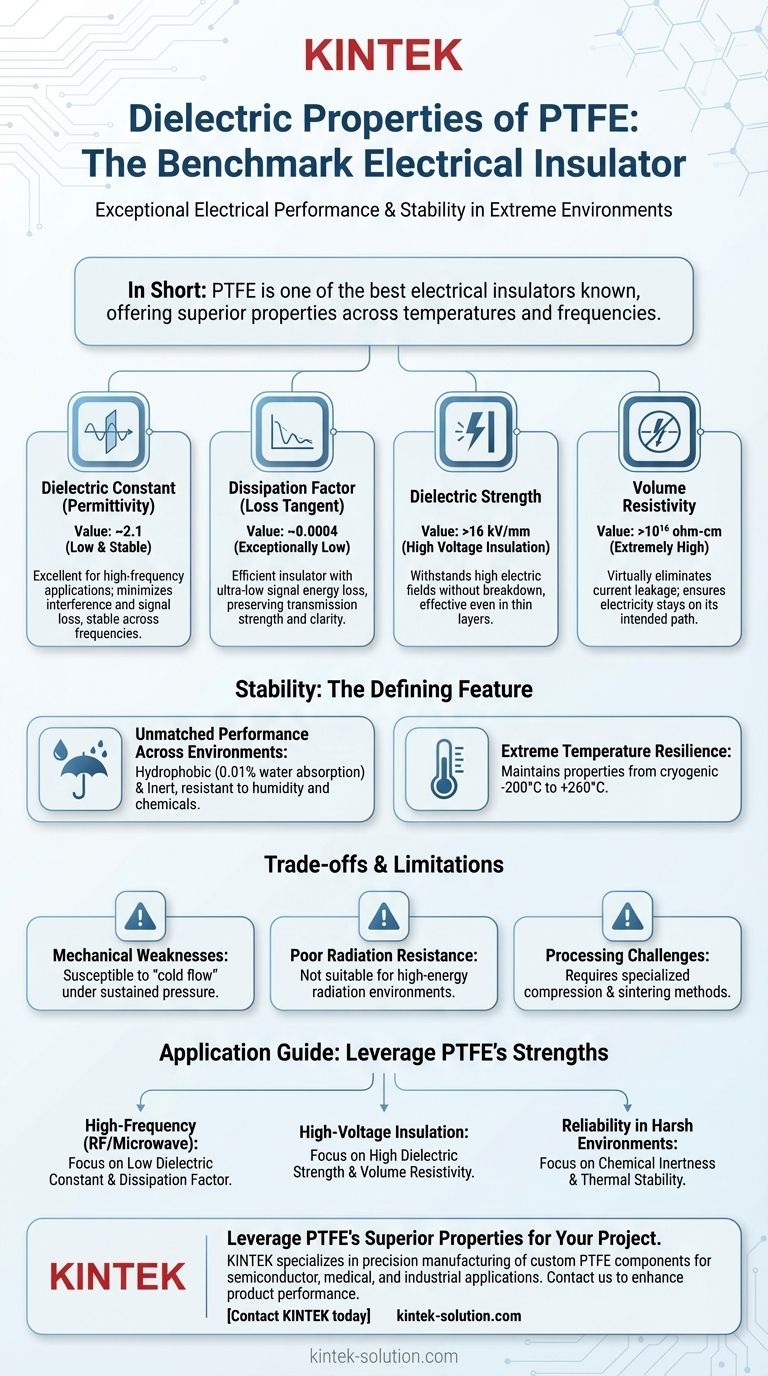

In short, Polytetrafluoroethylene (PTFE) is one of the best electrical insulators known. Its key dielectric properties include a very low dielectric constant of approximately 2.1, a low dissipation factor near 0.0004, extremely high volume resistivity exceeding 10¹⁶ ohm-cm, and a high dielectric strength of over 16 kV/mm. These figures confirm its exceptional ability to insulate and resist electrical breakdown.

The true value of PTFE isn't just its excellent individual dielectric numbers, but its remarkable ability to maintain these properties consistently across an extremely wide range of temperatures, frequencies, and harsh chemical environments.

Decoding PTFE's Electrical Insulation Performance

To understand why PTFE is a benchmark material in electronics and high-voltage applications, we need to look at the specific properties that define its performance. Each one plays a distinct role in its function as an elite insulator.

The Dielectric Constant (Permittivity)

The dielectric constant measures a material's ability to store electrical energy in an electric field. A lower value is better for high-frequency applications because it minimizes interference and signal loss.

PTFE's dielectric constant is very low, around 2.1. Crucially, this value remains stable across a wide frequency spectrum, making it ideal for RF and microwave components where signal integrity is paramount.

The Dissipation Factor (Loss Tangent)

The dissipation factor quantifies how much electrical energy is absorbed by the material and lost as heat. A lower number indicates a more efficient insulator that won't waste signal energy.

PTFE has an exceptionally low dissipation factor of approximately 0.0004. This means signals can pass through or alongside it with minimal energy loss, preserving the strength and clarity of the transmission.

Dielectric Strength

Dielectric strength is the maximum electric field a material can withstand without breaking down and conducting electricity. It's a measure of its voltage insulation capability.

PTFE boasts a high dielectric strength, typically exceeding 16 kV/mm. This allows it to insulate components effectively even when very thin layers of the material are used in high-voltage scenarios.

Volume Resistivity

Volume resistivity measures a material's resistance to leakage current flowing directly through it. Higher values signify better insulation.

With a volume resistivity greater than 10¹⁶ ohm-cm, PTFE is one of the most resistive materials available. It virtually eliminates current leakage, ensuring electricity stays on its intended path.

Why Stability is PTFE's Defining Feature

Many materials have good dielectric properties under ideal conditions. PTFE's elite status comes from its ability to perform in extreme and varied environments without degradation.

Unmatched Performance Across Environments

PTFE is almost completely inert and hydrophobic. With a water absorption of just 0.01%, its electrical properties are not compromised by humidity or direct moisture contact.

Furthermore, its superior chemical resistance means it can be used in corrosive environments without its insulating capabilities being affected.

Extreme Temperature Resilience

PTFE maintains its excellent dielectric properties from cryogenic temperatures (-200°C) up to its high service temperature (+260°C).

This thermal stability ensures reliable performance in applications ranging from aerospace systems to industrial processing equipment where temperature fluctuations are common.

Understanding the Trade-offs and Limitations

No material is perfect. While PTFE's electrical and chemical properties are world-class, its physical characteristics present certain limitations that are critical to understand.

Mechanical Weaknesses

PTFE is a relatively soft material with a low compression modulus. This makes it susceptible to "cold flow" or creep, where the material slowly deforms under sustained pressure. It is not suitable for high-load structural applications.

Poor Radiation Resistance

As noted in material data, PTFE has poor resistance to high-energy radiation. Ionizing radiation can break down the polymer's molecular chains, causing it to become brittle and lose its desirable properties. This makes it unsuitable for many nuclear and outer space applications.

Processing Challenges

PTFE's high melting point and extreme melt viscosity make it impossible to process using conventional techniques like injection molding. It must be formed using specialized compression and sintering methods, similar to those used in powder metallurgy, which can increase manufacturing complexity and cost.

How to Apply This to Your Project

Your specific goal will determine which of PTFE's properties is most critical for your design.

- If your primary focus is high-frequency electronics (RF, microwave): Its low and stable dielectric constant, combined with its ultra-low dissipation factor, is essential for preserving signal integrity.

- If your primary focus is high-voltage insulation: Its high dielectric strength and immense volume resistivity are the most important factors for preventing electrical breakdown and leakage.

- If your primary focus is reliability in harsh environments: Its unparalleled chemical inertness and thermal stability ensure its electrical properties will not degrade due to heat, moisture, or corrosion.

Ultimately, PTFE remains the material of choice when exceptional electrical performance cannot be compromised by extreme operational demands.

Summary Table:

| Property | Value | Significance |

|---|---|---|

| Dielectric Constant | ~2.1 | Excellent for high-frequency signals, minimal interference. |

| Dissipation Factor | ~0.0004 | Ultra-low signal energy loss, ideal for RF/microwave. |

| Dielectric Strength | >16 kV/mm | High voltage insulation, even in thin layers. |

| Volume Resistivity | >10¹⁶ ohm-cm | Prevents current leakage, superior insulation. |

| Key Advantage | Stable performance from -200°C to +260°C | Reliable in extreme thermal and harsh chemical environments. |

Leverage PTFE's Superior Dielectric Properties for Your Project

Do you need reliable, high-performance insulation that won't fail under extreme temperatures, harsh chemicals, or demanding electrical requirements? PTFE is the benchmark material for a reason.

KINTEK specializes in the precision manufacturing of custom PTFE components—including seals, liners, labware, and complex fabricated parts—for the semiconductor, medical, laboratory, and industrial sectors. We understand the critical role of dielectric stability and can help you integrate PTFE's advantages into your design.

From prototyping to high-volume production, we ensure the material's exceptional properties are delivered in a component that meets your exact specifications.

Contact KINTEK today to discuss your application and discover how our custom PTFE solutions can enhance your product's performance and reliability.

Visual Guide

Related Products

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

People Also Ask

- How do the chemical properties of PTFE balls influence their performance? Unmatched Durability in Harsh Environments

- What are the key chemical properties of PTFE balls? Unmatched Chemical & Thermal Stability

- What are the advantages of PTFE balls over metals or alloys? Superior Chemical & Friction Resistance

- What factors determine the different grades of PTFE balls available? Select the Right Grade for Your Application

- How do PTFE balls contribute to reduced maintenance costs? Extend Component Life and Cut Downtime