At its core, any industry that moves aggressive or high-purity fluids under demanding thermal and pressure conditions benefits from PTFE bellows. Key sectors include chemical and petrochemical processing, pharmaceuticals, food and beverage, semiconductor manufacturing, and aerospace. These industries rely on PTFE not just for its resistance to temperature and pressure, but for its unique combination of properties that ensures system integrity and purity.

While temperature and pressure resistance are key triggers for considering PTFE bellows, their true value lies in delivering these capabilities without compromising chemical compatibility or process purity. This unique intersection of properties makes them indispensable in today's most sensitive and aggressive industrial environments.

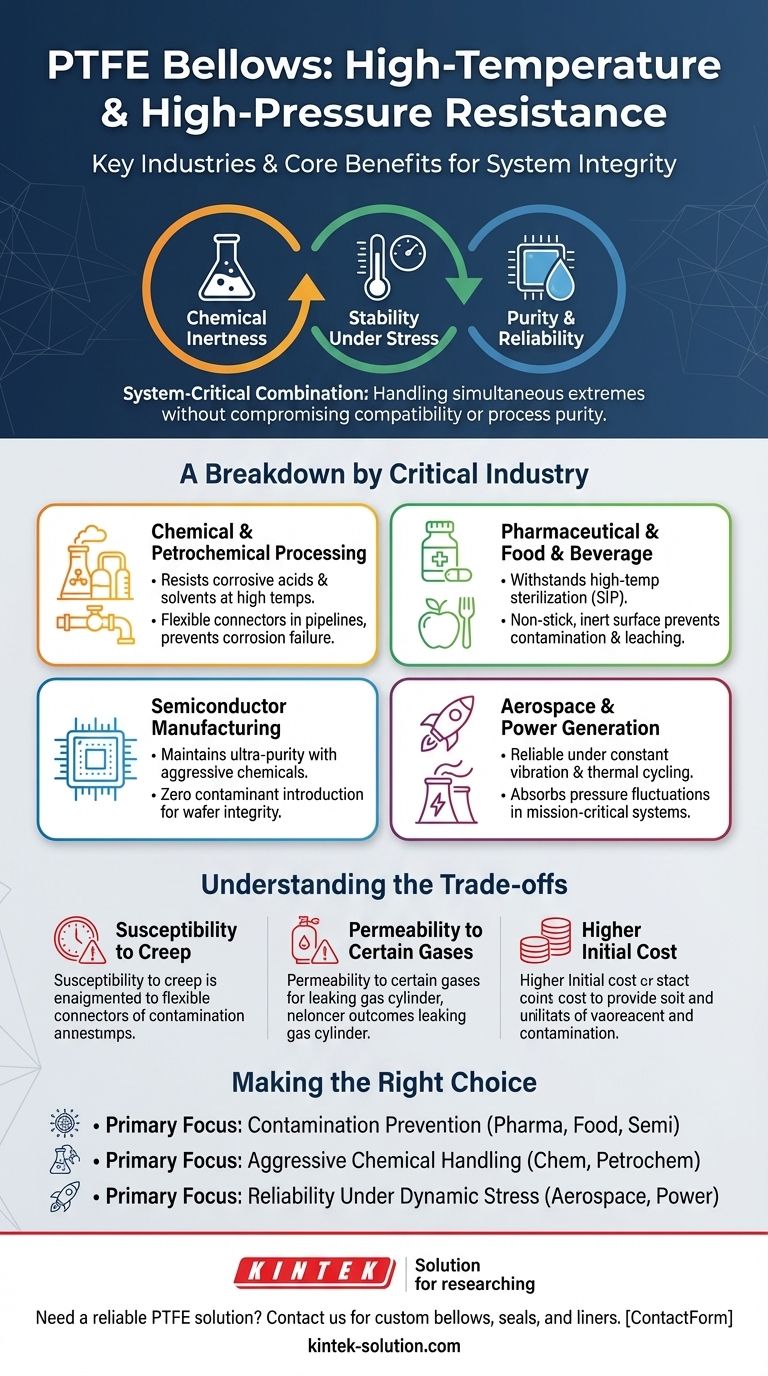

Why These Properties Are a System-Critical Combination

The question is not just about temperature and pressure alone. Many materials can handle one or the other. The defining advantage of Polytetrafluoroethylene (PTFE) is its ability to handle both simultaneously while adding other critical performance characteristics.

The Foundation: Unmatched Chemical Inertness

PTFE is famously inert, meaning it is non-reactive to nearly all industrial chemicals, acids, and solvents. This is the primary reason it is specified in applications involving corrosive or aggressive media. It eliminates the risk of the bellow itself degrading and failing.

The Multiplier: Stability Under Stress

The material's ability to withstand high temperatures (up to 260°C / 500°F) and significant pressures is what makes it so versatile. Crucially, PTFE maintains its chemical inertness and structural integrity across this wide operational window. It won’t become brittle in cryogenic applications or soften and leach chemicals when heated.

The Guarantee: Purity and Reliability

For industries like pharmaceuticals and semiconductors, process purity is non-negotiable. PTFE has an exceptionally low-friction, non-stick surface that resists the buildup of deposits and biofilm. This ensures a clean, uncontaminated fluid path and also prevents blockages, reducing maintenance and downtime.

A Breakdown by Critical Industry

Different industries leverage this combination of properties to solve specific, high-stakes problems.

Chemical and Petrochemical Processing

These industries handle some of the most corrosive substances, often at elevated temperatures and pressures. PTFE bellows serve as flexible connectors and expansion joints in pipelines, absorbing vibration and thermal expansion without being corroded by the process fluids. This prevents catastrophic leaks and extends the life of the entire piping system.

Pharmaceutical and Food & Beverage

Here, the primary concern is preventing contamination. PTFE bellows can withstand high-temperature sterilization processes, such as steam-in-place (SIP), without degrading. Their inert, non-stick surface ensures that no material from the bellow leaches into the product and that no cross-contamination occurs between batches.

Semiconductor Manufacturing

This is an environment of absolute purity. The manufacturing of microchips involves highly aggressive and ultra-pure chemicals. PTFE bellows are essential for handling these fluids because they introduce virtually zero contaminants into the process stream. Even a minuscule impurity can lead to the failure of an entire wafer of chips.

Aerospace and Power Generation

In these sectors, reliability under extreme operational stress is paramount. PTFE bellows function as flexible joints in fluid and fuel lines, absorbing constant vibration, pressure fluctuations, and thermal cycling (rapid changes from hot to cold). Their stability ensures system integrity in mission-critical applications where failure is not an option.

Understanding the Trade-offs

No material is a perfect solution for every problem. Being a trusted advisor means acknowledging the limitations of PTFE.

Susceptibility to Creep

Like other fluoropolymers, PTFE can be subject to "creep"—a tendency to deform slowly over time when under a constant load, a process that accelerates at higher temperatures. This must be a key consideration during the engineering and design phase of any system using PTFE components under sustained stress.

Permeability to Certain Gases

While excellent for liquids, PTFE is not completely impermeable to all small-molecule gases. In high-vacuum systems or applications handling specific gases like hydrogen or helium, its permeability rate must be evaluated to ensure it meets system requirements.

Higher Initial Cost

PTFE components often have a higher upfront cost compared to alternatives like EPDM rubber or even some metals. However, this is frequently offset by a lower total cost of ownership due to PTFE's longer lifespan, reduced maintenance needs, and prevention of costly failures and downtime.

Making the Right Choice for Your Application

The decision to use PTFE bellows should be based on the most critical requirement of your system.

- If your primary focus is preventing contamination: PTFE is the definitive choice for pharmaceutical, food, and semiconductor applications due to its inertness and ability to withstand sterilization.

- If your primary focus is handling aggressive chemicals: PTFE's near-universal chemical resistance makes it the default solution for chemical and petrochemical processing pipelines, ensuring long-term system safety.

- If your primary focus is reliability under dynamic stress: PTFE bellows provide essential flexibility and shock absorption in aerospace, power generation, and complex piping systems where thermal and mechanical stability are paramount.

Understanding these core principles allows you to select a material based not just on its specifications, but on its ability to ensure the long-term integrity and efficiency of your entire system.

Summary Table:

| Industry | Key Benefit of PTFE Bellows | Critical Application |

|---|---|---|

| Chemical & Petrochemical | Resists aggressive acids/solvents at high temps | Flexible connectors in corrosive pipelines |

| Pharmaceutical & Food | Withstands sterilization, prevents contamination | Steam-in-place (SIP) systems, batch processing |

| Semiconductor | Maintains ultra-purity with aggressive chemicals | Handling high-purity etchants and solvents |

| Aerospace & Power | Reliable under vibration and thermal cycling | Fuel/fluid lines in mission-critical systems |

Need a reliable PTFE solution for your demanding application? KINTEK specializes in manufacturing high-performance PTFE components—including custom bellows, seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. We ensure precision production and custom fabrication from prototypes to high-volume orders, delivering the chemical resistance, purity, and durability your system requires. Contact us today to discuss your specific needs and let our expertise enhance your operational integrity!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are important tips for turning PTFE on a lathe? Achieve a Clean, Precise Cut Every Time

- What temperature range can machined PTFE parts withstand? From Cryogenic -200°C to High-Temp +260°C

- What types of devices are Teflon bellow mechanical seals used in? A Guide for Extreme Conditions

- What are the key properties of Expanded PTFE (EPTFE) gaskets? Solve Leaks on Damaged Flanges

- What are the challenges in manufacturing PTFE impellers? Overcoming the Complexities of Machining

- What are the benefits of using PTFE lined valves? Achieve Superior Reliability in Corrosive Applications

- In which industries are PTFE oil seals commonly used? Ensuring Reliability in Extreme Conditions

- What are the electrical and electronic applications of PTFE? High-Performance Insulation for Demanding Environments