Manufacturing a PTFE impeller is fundamentally a process of precision carving, not molding. The primary challenges arise because Polytetrafluoroethylene (PTFE) cannot be melt-processed like common plastics. This forces every impeller to be individually machined from a solid block, a time-consuming and complex task that requires specialized equipment and deep expertise in polymer science.

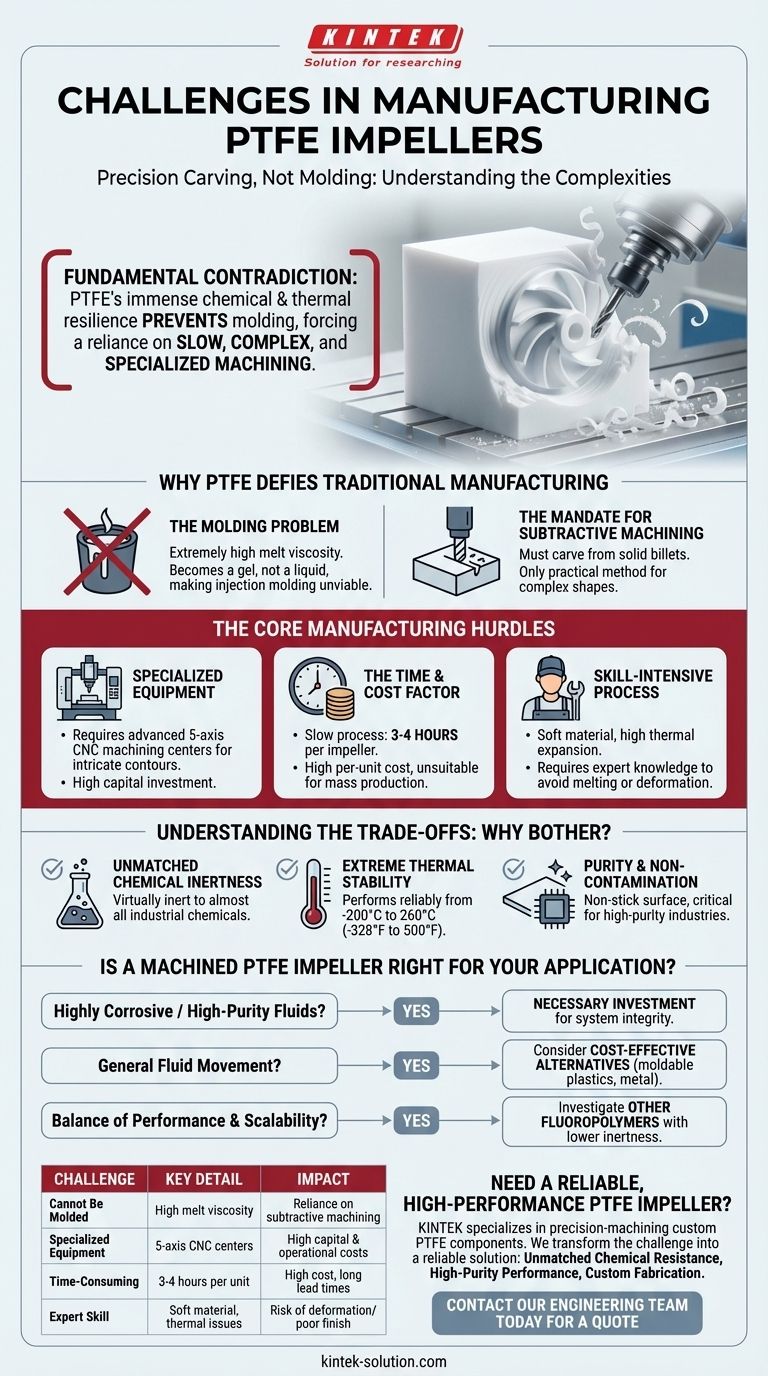

The central challenge in PTFE impeller manufacturing lies in a fundamental contradiction: the material's immense chemical and thermal resilience prevents it from being molded, forcing a reliance on slow, complex, and highly specialized machining processes.

Why PTFE Defies Traditional Manufacturing

To understand the manufacturing hurdles, we must first understand the unique nature of the material itself. Unlike most thermoplastics, PTFE does not transition to a usable liquid state when heated.

The Molding Problem

PTFE has an extremely high melt viscosity. When heated to its melting point, it doesn't flow but instead becomes a translucent, gel-like substance.

This behavior makes conventional manufacturing methods like injection molding completely unviable, as the material cannot be forced into the intricate cavities of a mold.

The Mandate for Subtractive Machining

Because molding is not an option, the only practical method for creating a complex shape like an impeller is subtractive manufacturing.

This involves starting with a solid billet of PTFE and systematically cutting away material to reveal the final form. This reality is the source of all subsequent challenges.

The Core Manufacturing Hurdles

Machining an impeller from a solid block introduces significant complexities in terms of equipment, time, and the required skill set.

Requirement for Specialized Equipment

The complex geometry of an impeller, with its curved vanes and intricate contours, cannot be produced on standard machinery.

Manufacturing necessitates the use of advanced 5-axis CNC machining centers. This equipment is expensive to acquire and operate, representing a significant capital investment.

The Time and Cost Factor

The machining process is not fast. Each individual impeller can take 3 to 4 hours to machine from a solid block.

This slow, one-at-a-time production method makes PTFE impellers inherently expensive and unsuitable for high-volume, mass-production scenarios.

The Skill-Intensive Machining Process

PTFE is notoriously difficult to machine correctly. It is a soft material with a high rate of thermal expansion and low thermal conductivity.

An operator requires expert knowledge of both machining techniques and polymer properties. Using the wrong tool speed or feed rate can cause the material to melt, deform, or result in a poor surface finish, rendering the part useless.

Understanding the Trade-offs: Why Bother with PTFE?

Given these significant manufacturing challenges, the decision to use PTFE is always driven by an application's extreme demands, where no other material will suffice.

Unmatched Chemical Inertness

PTFE is virtually inert to almost all industrial chemicals and solvents. This makes it the only viable choice for impellers that must handle highly corrosive or aggressive fluids without degrading.

Extreme Thermal Stability

The material maintains its properties across a vast temperature range, typically from -200°C to 260°C (-328°F to 500°F). This allows it to perform reliably in applications involving extreme cold or heat where other polymers would fail.

Purity and Non-Contamination

PTFE has a non-stick, low-friction surface. This is critical in high-purity industries like semiconductors and pharmaceuticals, as it minimizes the potential for fluid contamination and particle buildup on the impeller's surface.

Is a Machined PTFE Impeller Right for Your Application?

Choosing this component requires weighing its unparalleled performance against its significant manufacturing constraints.

- If your primary focus is handling highly corrosive or high-purity fluids: The high cost and lead time of a machined PTFE impeller are a necessary investment to ensure system integrity and prevent contamination.

- If your primary focus is general fluid movement in a non-aggressive environment: A traditional impeller made from a moldable plastic (like polypropylene) or metal will be a far more cost-effective and readily available solution.

- If your primary focus is a balance of performance and scalability: You may need to investigate alternative, more easily processable fluoropolymers, accepting they may not offer the absolute inertness of PTFE.

Ultimately, choosing a machined PTFE impeller is a deliberate engineering decision where you accept significant manufacturing complexity in exchange for unparalleled material performance.

Summary Table:

| Challenge | Key Detail | Impact |

|---|---|---|

| Cannot Be Molded | PTFE's high melt viscosity prevents injection molding. | Forces reliance on subtractive machining. |

| Specialized Equipment | Requires advanced 5-axis CNC machining centers. | High capital investment and operational costs. |

| Time-Consuming Process | Each impeller takes 3-4 hours to machine. | Results in high per-unit cost and longer lead times. |

| Expert Machining Skill | Soft material with high thermal expansion requires precise tool control. | Risk of part deformation or poor finish without expert knowledge. |

Need a Reliable, High-Performance PTFE Impeller?

Navigating the complexities of PTFE machining requires a partner with deep expertise in both advanced manufacturing and polymer science. KINTEK specializes in precision-machining custom PTFE components, including impellers, for the semiconductor, medical, laboratory, and industrial sectors.

We transform the challenge of PTFE into a reliable solution for you, ensuring:

- Unmatched Chemical Resistance for handling corrosive fluids.

- High-Purity Performance critical for sensitive applications.

- Custom Fabrication from prototypes to high-volume production runs.

Let's discuss your specific application requirements. Contact our engineering team today to get a quote and see how we can deliver the precision and performance your project demands.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Parts Manufacturer PTFE Magnetic Stirring Bar

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs