The primary benefits of using PTFE lined valves are exceptional chemical resistance, high thermal stability, and non-stick surface properties. This combination results in a highly durable and reliable valve that minimizes maintenance, prevents leaks, and extends the lifespan of your piping system when handling corrosive or aggressive substances.

A PTFE lined valve is not just a component; it's a long-term strategy for reducing operational risk and total cost of ownership in demanding industrial environments. It solves the core problems of corrosion, contamination, and leakage that plague standard valves.

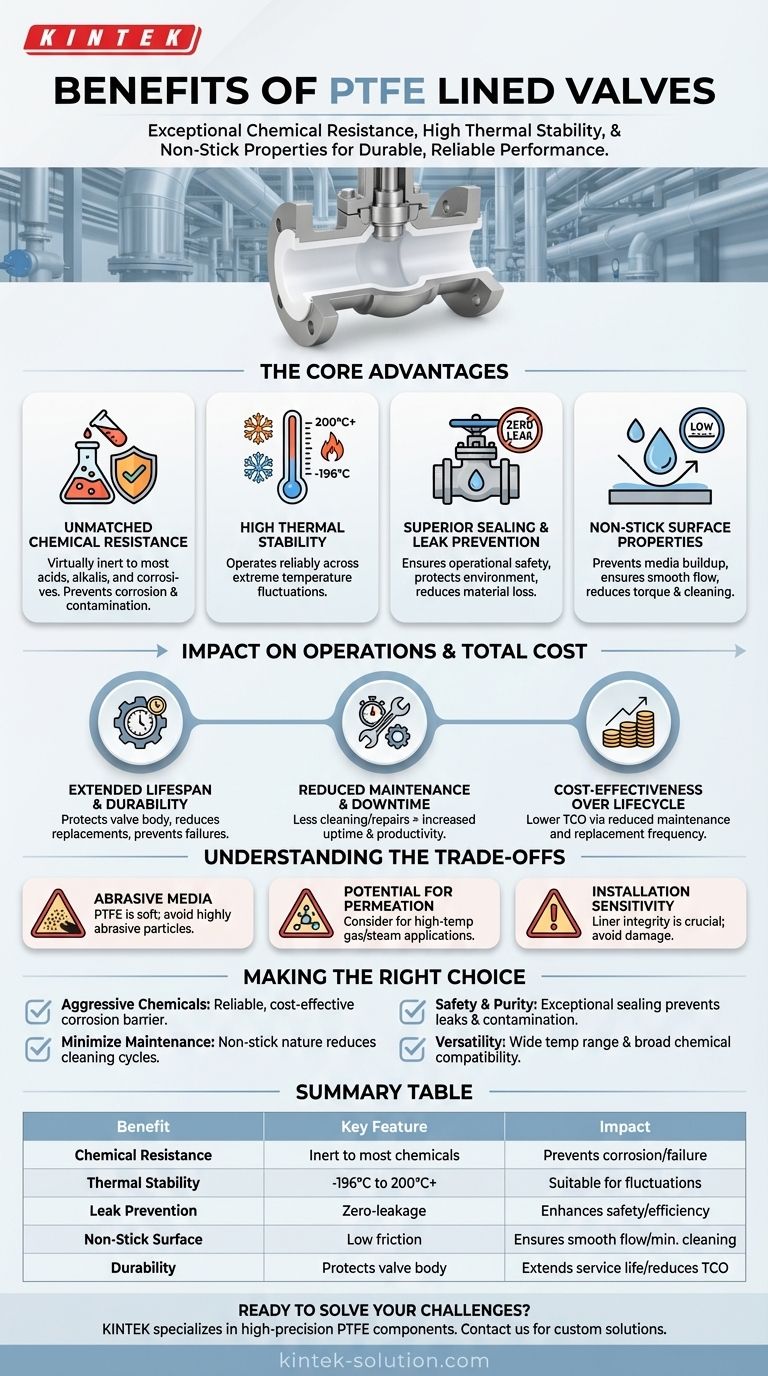

The Core Advantages of a PTFE Lining

Polytetrafluoroethylene (PTFE) is an engineered fluoropolymer that imparts unique and powerful characteristics to the valves it lines. Understanding these properties is key to appreciating their value in an industrial setting.

Unmatched Chemical Resistance

PTFE is virtually inert to almost all industrial chemicals. It can withstand strong acids, alkalis, corrosive media, and powerful oxidants without degrading.

This universal chemical resistance prevents corrosion of the valve's core components, ensuring the integrity of the system and preventing contamination of the process media.

High Thermal Stability

These valves operate reliably across an extremely wide temperature range, typically from cryogenic temperatures (-196°C) up to 200°C or higher.

This versatility makes them suitable for processes that involve significant temperature fluctuations, from chemical processing to water treatment.

Superior Sealing and Leak Prevention

The design and material properties of PTFE liners often allow for zero-leakage performance. This tight seal is critical for operational safety.

By eliminating leaks, you prevent the release of hazardous substances, protecting personnel and the environment while also improving process efficiency and reducing material loss.

Non-Stick Surface Properties

PTFE is famous for its low coefficient of friction, creating a non-stick surface. This prevents media from building up inside the valve.

This characteristic ensures a smooth, consistent flow, reduces the torque needed to operate the valve, and drastically cuts down on the need for cleaning and maintenance.

The Impact on Operations and Total Cost

Choosing a PTFE lined valve goes beyond its technical specifications; it has a direct and positive impact on your operational efficiency, safety, and budget.

Extended Lifespan and Durability

By protecting the valve body from corrosion and wear, the PTFE lining dramatically extends the component's service life.

This durability reduces the frequency of costly replacements and lessens the risk of catastrophic pipeline failures, which can halt production and incur massive costs.

Reduced Maintenance and Downtime

The combination of durability and non-stick properties means these valves require significantly less maintenance.

Less time spent on repairs and cleaning translates directly to increased operational uptime and higher productivity for your facility.

Cost-Effectiveness Over the Lifecycle

While the initial purchase price may be different from a basic valve, PTFE lined valves are often more cost-effective than those made from expensive specialty alloys like stainless steel.

When you factor in the reduced maintenance, lower replacement frequency, and prevention of costly failures, the total cost of ownership is often significantly lower.

Understanding the Trade-offs

No single solution is perfect for every scenario. To make an informed decision, it's critical to understand the limitations of PTFE linings.

Susceptibility to Abrasive Media

While chemically robust, PTFE is a relatively soft material. It is not ideal for services containing highly abrasive particles or slurries, which can wear down or damage the liner over time.

Potential for Permeation

In certain high-temperature gas or steam applications, very small molecules can sometimes permeate the PTFE liner. This is a specific consideration that must be evaluated for the intended service.

Installation Sensitivity

The integrity of the valve depends entirely on the integrity of the liner. Care must be taken during installation to avoid scratching, gouging, or otherwise damaging the PTFE surface, as this would create a weak point for chemical attack.

Making the Right Choice for Your Application

Selecting the correct valve depends on identifying your most critical operational goal.

- If your primary focus is handling aggressive chemicals: PTFE's near-universal chemical inertness provides one of the most reliable and cost-effective barriers against corrosion available.

- If your primary focus is minimizing maintenance and downtime: The non-stick, durable nature of a PTFE lining reduces cleaning cycles, prevents buildup, and extends the valve's service life.

- If your primary focus is ensuring safety and media purity: The exceptional sealing capability prevents hazardous leaks, while the inert material protects sensitive media (like pharmaceuticals or foods) from contamination.

- If your primary focus is versatility: The wide operating temperature range and broad chemical compatibility make PTFE lined valves a robust choice for a diverse set of industrial applications.

Ultimately, choosing a PTFE lined valve is an investment in the long-term reliability and safety of your entire process.

Summary Table:

| Benefit | Key Feature | Impact on Operations |

|---|---|---|

| Chemical Resistance | Virtually inert to most industrial chemicals | Prevents corrosion, contamination, and system failure |

| Thermal Stability | Operates from -196°C to 200°C+ | Suitable for processes with extreme temperature fluctuations |

| Leak Prevention | Zero-leakage performance and superior sealing | Enhances safety, protects the environment, and improves efficiency |

| Non-Stick Surface | Low coefficient of friction prevents media buildup | Reduces torque, ensures smooth flow, and minimizes cleaning |

| Durability | Protects valve body from wear and corrosion | Extends service life and reduces total cost of ownership |

Ready to solve your corrosion and contamination challenges?

KINTEK specializes in manufacturing high-precision PTFE components, including custom-lined valves, seals, and labware for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get a solution tailored to your exact process requirements, delivering long-term reliability and reduced operational costs.

Contact KINTEK today to discuss your application and discover how our PTFE solutions can enhance your system's performance and safety.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support