At its core, a Teflon bellow mechanical seal is used in critical rotating equipment where preventing leaks is non-negotiable. You will find them primarily in devices like pumps, mixers, agitators, and valves, especially when the system must handle highly corrosive, abrasive, or high-temperature fluids that would quickly degrade conventional seals.

The decision to use a Teflon bellow seal is driven less by the type of machine and more by the extreme nature of the fluid being processed. Its purpose is to provide a reliable seal in environments where other materials would chemically decompose or fail.

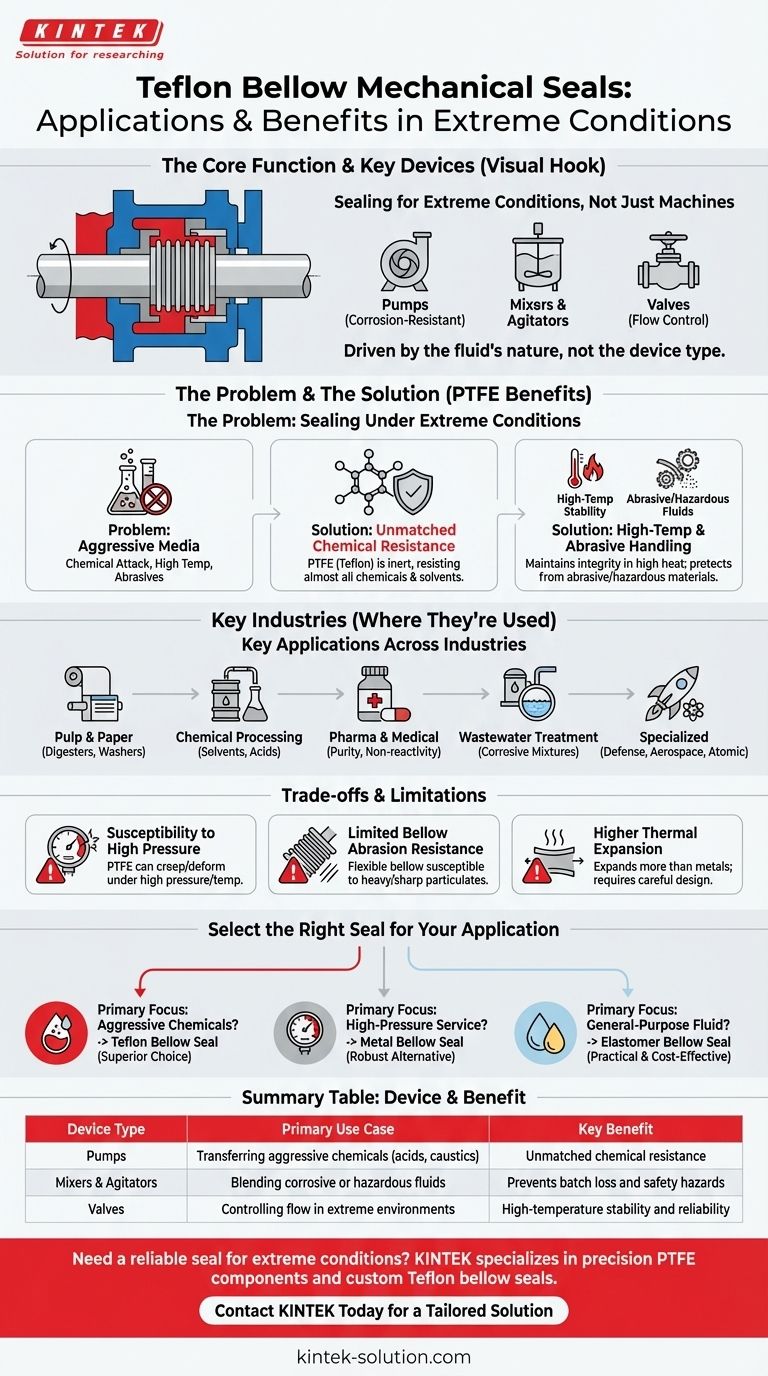

The Core Problem: Sealing Under Extreme Conditions

A mechanical seal's job is to contain fluid within a rotating piece of equipment. While many materials can do this with water or oil, the challenge escalates dramatically when dealing with aggressive media. This is the specific problem the Teflon bellow seal is engineered to solve.

Unmatched Chemical Resistance

The primary advantage of these seals comes from their construction material, Polytetrafluoroethylene (PTFE), commonly known as Teflon. PTFE is virtually inert, meaning it resists attack from almost all industrial chemicals and solvents.

This makes it the go-to choice for applications in the chemical, pharmaceutical, and food processing industries where product purity and equipment longevity are paramount.

High-Temperature Stability

Many industrial processes, such as pulp digestion in paper manufacturing, operate at elevated temperatures. Teflon bellow seals are designed to maintain their structural integrity and sealing capability under these demanding thermal conditions.

This prevents the escape of hazardous or environmentally harmful substances, ensuring the safety and reliability of the process equipment.

Handling Abrasive and Hazardous Fluids

In addition to chemical and thermal resistance, these seals are frequently used in systems that move fluids containing abrasive particles. The design helps protect equipment and prevent leaks of materials that could be dangerous to personnel or the environment.

Where You'll Find These Seals: Key Applications

While the principle is consistent, the application of Teflon bellow seals spans a vast range of industries and specific pieces of equipment.

In Industrial Pumps

Pumps are the most common application for these seals. They are particularly prevalent in corrosion-resistant pumps designed specifically for transferring acids, caustics, and other aggressive chemicals. A PTFE bellow seal is often the default choice in this context.

In Mixers and Agitators

Equipment used for blending, mixing, and agitating chemicals relies heavily on reliable sealing. A seal failure in a mixer can ruin a batch, damage the equipment, and create a significant safety hazard. Teflon bellows provide the necessary resilience.

Across Specialized Industries

The versatility of PTFE makes these seals critical components in a wide array of sectors. You will find them in:

- Pulp and Paper: In digesters, washers, and pumps.

- Chemical Processing: Handling everything from solvents to acids.

- Pharmaceutical & Medical: Where purity and non-reactivity are essential.

- Wastewater Treatment: Resisting a complex mixture of corrosive chemicals.

- Defense, Aerospace, and Atomic Energy: For specialized and demanding fluid-handling applications.

Understanding the Trade-offs

No engineering solution is without its limitations. Being a trusted advisor means acknowledging the situations where a Teflon bellow seal might not be the best choice.

Susceptibility to High Pressure

While excellent for chemical resistance, PTFE is a relatively soft material that can creep or deform under high pressure, especially when combined with high temperatures. In high-pressure applications, a different seal design, such as a metal bellow seal, might be required.

Limited Abrasion Resistance of the Bellows

The seal faces (often made of carbon, ceramic, or silicon carbide) handle the primary wear and tear. However, the flexible PTFE bellow itself can be susceptible to damage in applications with very heavy or sharp particulate matter.

Higher Thermal Expansion

PTFE expands and contracts with temperature changes more than metals do. This must be accounted for in the seal's design and installation to ensure the seal faces remain properly loaded and effective across the full operating temperature range.

Making the Right Choice for Your Application

Selecting the correct seal is about matching the material and design to the specific operational challenge your equipment faces.

- If your primary focus is handling aggressive chemicals: The Teflon bellow seal is almost always the superior choice due to its chemical inertness.

- If your primary focus is high-pressure service: Carefully evaluate the pressure and temperature ratings, and consider a metal bellow seal as a more robust alternative.

- If your primary focus is general-purpose fluid handling (like water or mild oils): A less expensive seal with an elastomer bellow is likely a more practical and cost-effective solution.

Ultimately, choosing the right seal ensures the safety, reliability, and efficiency of your entire process.

Summary Table:

| Device Type | Primary Use Case | Key Benefit |

|---|---|---|

| Pumps | Transferring aggressive chemicals (acids, caustics) | Unmatched chemical resistance |

| Mixers & Agitators | Blending corrosive or hazardous fluids | Prevents batch loss and safety hazards |

| Valves | Controlling flow in extreme environments | High-temperature stability and reliability |

Need a reliable seal for extreme conditions? KINTEK specializes in precision PTFE components, including custom Teflon bellow seals for semiconductor, medical, laboratory, and industrial applications. We ensure your equipment handles corrosive, high-temperature, or abrasive fluids safely—from prototypes to high-volume orders. Contact us today to discuss your sealing challenges and get a solution tailored to your needs!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining