PTFE oil seals are indispensable in a wide range of demanding industries. They are the material of choice for aerospace, high-performance automotive, chemical processing, food and pharmaceutical manufacturing, and heavy industrial sectors like energy and construction. Their adoption is driven by an exceptional ability to perform reliably under extreme operational conditions where standard seals would fail.

The widespread use of PTFE seals is not due to a single feature, but a unique combination of properties. Their capacity to simultaneously resist extreme temperatures, aggressive chemicals, and high pressures makes them the default choice for critical applications where reliability is paramount.

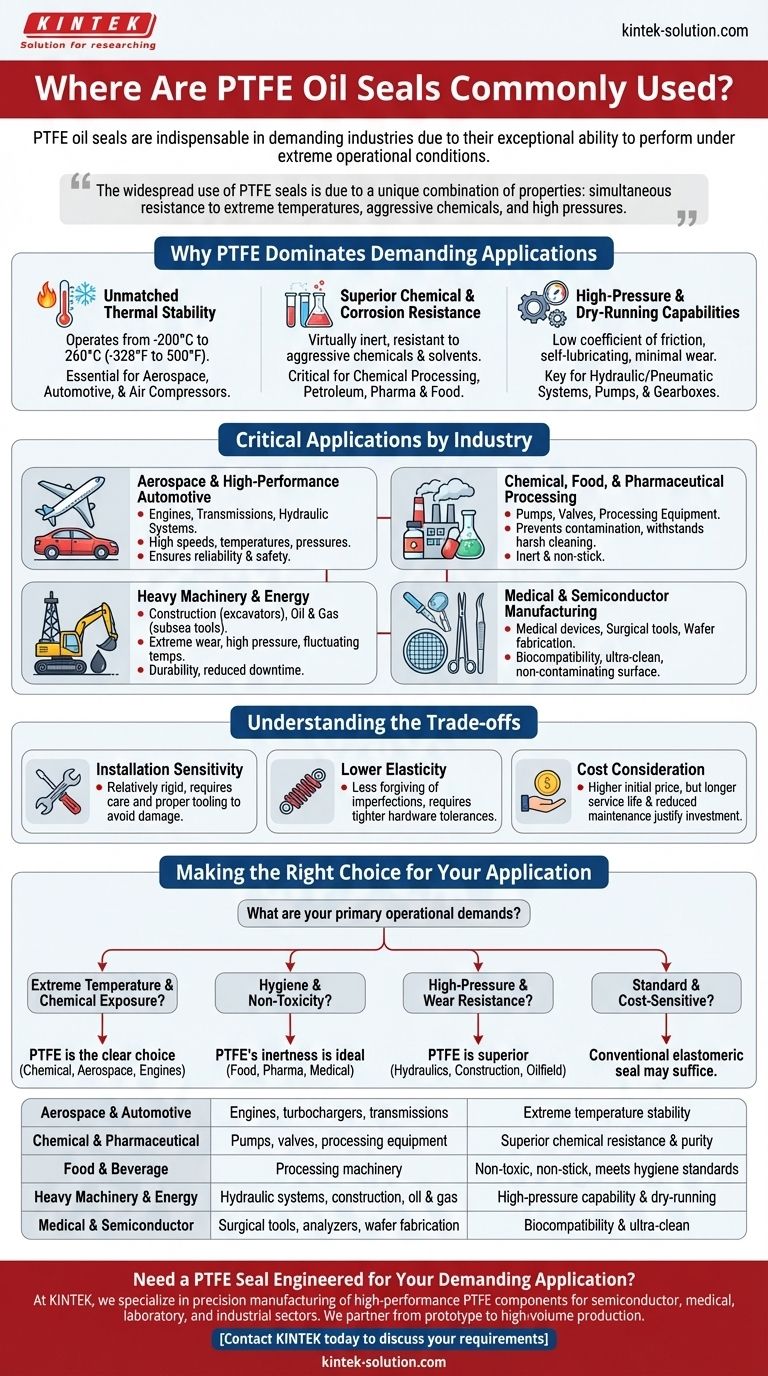

Why PTFE Dominates Demanding Applications

The decision to use a PTFE seal is fundamentally a decision to engineer for resilience. The material's core characteristics directly address the most common points of failure in industrial equipment.

Unmatched Thermal Stability

PTFE seals operate effectively across an exceptionally wide temperature range, typically from -200°C to 260°C (-328°F to 500°F).

This thermal resilience makes them essential in aerospace engines, automotive turbochargers, and industrial air compressors, where extreme heat is a constant.

Superior Chemical and Corrosion Resistance

PTFE is virtually inert, meaning it does not react with most chemicals, including aggressive acids, solvents, and oils.

This property is critical in chemical processing plants and petroleum industry equipment (like downhole tools) that handle corrosive fluids. It also ensures purity in pharmaceutical and food processing applications.

High-Pressure and Dry-Running Capabilities

PTFE has an extremely low coefficient of friction, allowing it to handle high-pressure environments with minimal wear and heat generation.

This self-lubricating nature also means PTFE seals can operate in "dry running" conditions without immediate failure. This is a key advantage in hydraulic and pneumatic systems, pumps, and gearboxes.

Critical Applications by Industry

While the material properties explain the "why," seeing where PTFE seals are deployed clarifies their practical value.

Aerospace and High-Performance Automotive

In these sectors, components like engines, transmissions, and hydraulic systems operate at high speeds, temperatures, and pressures. PTFE seals provide the necessary reliability to prevent leaks and ensure operational safety.

Chemical, Food, and Pharmaceutical Processing

Here, the primary concerns are preventing contamination and withstanding harsh cleaning agents. PTFE's chemical inertness, non-stick surface, and compliance with food safety standards make it the ideal sealing material.

Heavy Machinery and Energy

Equipment used in construction (excavators, loaders) and the oil and gas industry (subsea equipment, HPHT tools) faces extreme wear, high pressure, and fluctuating temperatures. PTFE's durability ensures longer service intervals and reduced downtime.

Medical and Semiconductor Manufacturing

In medical devices like surgical tools and analyzers, PTFE's biocompatibility prevents adverse reactions. In semiconductor manufacturing, its non-stick, non-contaminating surface is vital for maintaining the ultra-clean environments required for production.

Understanding the Trade-offs

While highly effective, PTFE seals are not a universal solution. An objective assessment requires acknowledging their specific limitations.

Installation Sensitivity

PTFE is a relatively rigid material compared to traditional elastomers like rubber. This means installation requires greater care and proper tooling to avoid scratching or damaging the sealing lip, which could compromise its effectiveness.

Lower Elasticity

Unlike rubber, PTFE has very little elastic "memory." It is less forgiving of imperfections in the shaft surface or out-of-round conditions. The hardware it seals against must be manufactured to tighter tolerances.

Cost Consideration

PTFE seals typically have a higher initial purchase price than standard elastomeric seals. However, this cost is often justified by significantly longer service life, reduced maintenance, and the prevention of costly failures in critical systems.

Making the Right Choice for Your Application

Selecting the correct seal depends entirely on the operational demands of your equipment.

- If your primary focus is extreme temperature and chemical exposure: PTFE is the clear choice for applications in chemical processing, aerospace, or high-performance engines.

- If your primary focus is hygiene and non-toxicity: PTFE's inertness and non-stick surface make it ideal for food, pharmaceutical, and medical equipment.

- If your primary focus is high-pressure and wear resistance: PTFE is a superior option for demanding hydraulic systems, heavy construction machinery, and oilfield tools.

- If your application is standard and cost-sensitive: A conventional elastomeric (rubber) seal may be sufficient, provided that temperatures and chemical exposures are moderate.

Ultimately, selecting a PTFE seal is a strategic decision to ensure reliability and longevity in environments where failure is not an option.

Summary Table:

| Industry | Key Application | Primary PTFE Benefit |

|---|---|---|

| Aerospace & Automotive | Engines, turbochargers, transmissions | Extreme temperature stability (-200°C to 260°C) |

| Chemical & Pharmaceutical | Pumps, valves, processing equipment | Superior chemical resistance & purity |

| Food & Beverage | Processing machinery | Non-toxic, non-stick, meets hygiene standards |

| Heavy Machinery & Energy | Hydraulic systems, construction equipment, oil & gas tools | High-pressure capability & dry-running performance |

| Medical & Semiconductor | Surgical tools, analyzers, wafer fabrication | Biocompatibility & ultra-clean non-contaminating surface |

Need a PTFE Seal Engineered for Your Demanding Application?

At KINTEK, we specialize in the precision manufacturing of high-performance PTFE components, including seals, liners, and custom labware. Whether you're in the semiconductor, medical, laboratory, or industrial sector, our expertise ensures you get a reliable solution tailored to withstand your specific extreme conditions—from aggressive chemicals to high temperatures and pressures.

We partner with you from prototype to high-volume production, ensuring quality and performance are never compromised.

Contact KINTEK today to discuss your requirements and let our experts provide a sealing solution that enhances your equipment's reliability and longevity.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments