At its core, Polytetrafluoroethylene (PTFE) offers a unique combination of three industrial advantages that few other materials can match. It provides near-total chemical inertness, the lowest coefficient of friction of any solid material, and exceptional performance across a vast temperature range. These properties make it a premier problem-solving material for some of the most demanding industrial environments.

The true advantage of PTFE isn't just a single property, but its ability to deliver extreme reliability where other materials fail. Choosing PTFE is an investment in reducing long-term costs associated with maintenance, downtime, and component failure in harsh operating conditions.

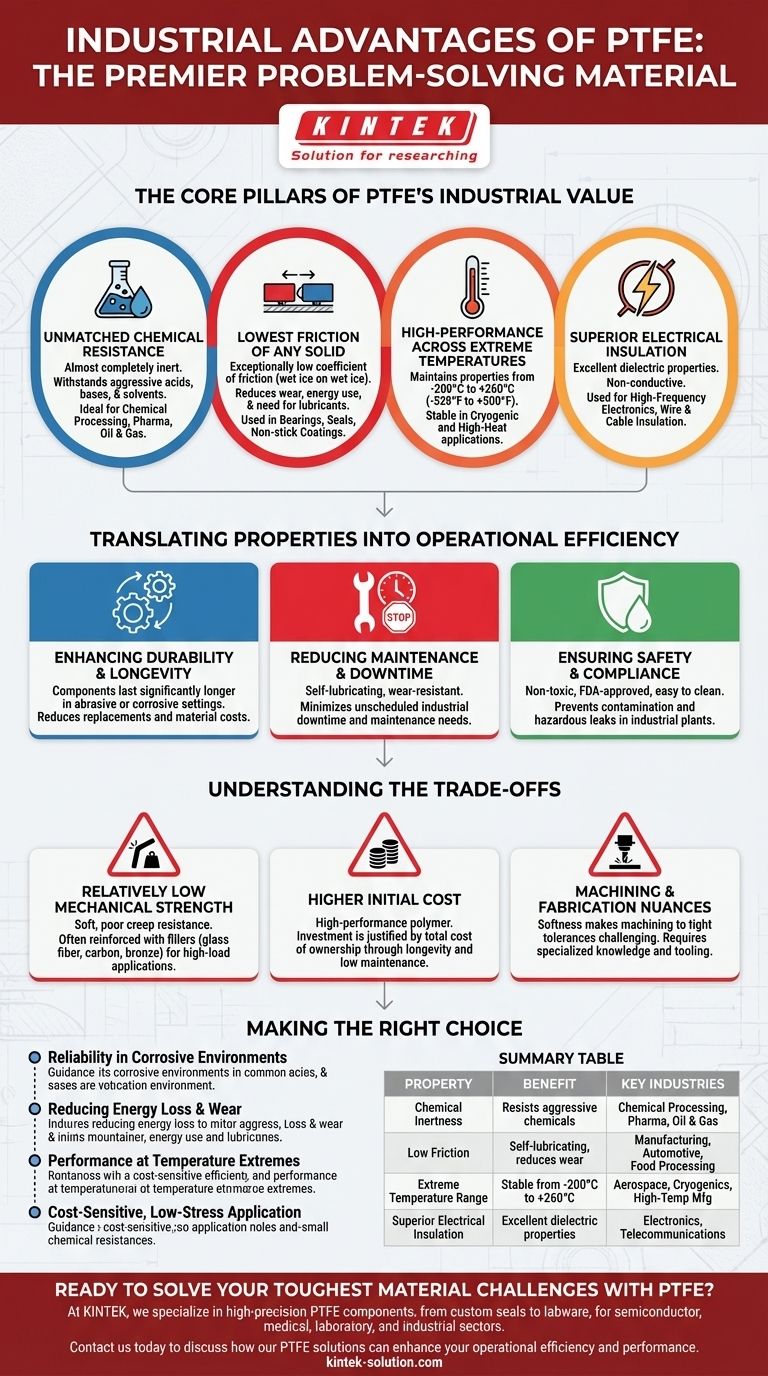

The Core Pillars of PTFE's Industrial Value

To understand why PTFE is so widely adopted, we must look at its fundamental material characteristics. These properties are the foundation of its performance and versatility.

Unmatched Chemical Resistance

PTFE is a fluoropolymer, characterized by incredibly strong carbon-fluorine bonds. This molecular structure makes it almost completely inert.

It can withstand aggressive acids, bases, and solvents that would degrade most other plastics and even many metals. This makes it an essential material for the chemical processing, pharmaceutical, and oil and gas industries.

The Lowest Friction of Any Solid

PTFE has an exceptionally low coefficient of friction, often compared to wet ice on wet ice. This means components move against each other with minimal resistance.

This property is critical for applications like bearings, seals, and non-stick coatings. It reduces wear and tear on machinery, lowers energy consumption, and often eliminates the need for liquid lubricants.

High-Performance Across Extreme Temperatures

PTFE maintains its properties across a remarkably wide operating temperature range, typically from -200°C to +260°C (-328°F to +500°F).

Unlike many plastics that become brittle in cryogenic conditions or melt at high temperatures, PTFE remains stable and functional, making it indispensable for aerospace, food processing, and specialized manufacturing.

Superior Electrical Insulation

PTFE possesses outstanding dielectric properties, meaning it does not conduct electricity. This makes it an excellent insulator.

It is widely used for high-frequency applications in electronics, as well as for insulating wires and cables, particularly in environments where chemical or thermal resistance is also required.

Translating Properties into Operational Efficiency

The true industrial advantage of PTFE is how its core properties translate into tangible benefits like lower costs, increased safety, and improved productivity.

Enhancing Durability and Longevity

Components made from or coated with PTFE—such as valves, gaskets, and seals—have a significantly longer service life, especially in abrasive or corrosive settings.

This inherent durability means less frequent need for replacements, directly cutting down on material and labor costs over the component's lifecycle.

Reducing Maintenance and Downtime

Because PTFE parts last longer and resist wear, they require minimal maintenance. The self-lubricating nature of the material further reduces the need for regular upkeep.

This reliability is crucial in manufacturing, as it minimizes unscheduled industrial downtime, one of the most significant hidden costs in any production environment.

Ensuring Safety and Compliance

PTFE is non-toxic and FDA-approved for food and drink applications. Its non-wetting, non-stick surface is also easy to clean, preventing contamination.

Furthermore, its reliability in sealing applications is a major safety benefit, preventing leaks of hazardous chemicals in industrial plants.

Understanding the Trade-offs

No material is perfect, and being a trusted advisor means acknowledging a material's limitations. Understanding PTFE's trade-offs is key to using it effectively.

Relatively Low Mechanical Strength

Compared to other engineering plastics, PTFE is relatively soft and has poor resistance to "creep" (deformation under sustained load).

For high-load mechanical applications, PTFE is often reinforced with fillers like glass fiber, carbon, or bronze to improve its strength and durability.

Higher Initial Cost

PTFE is a high-performance polymer, and its initial cost is higher than that of commodity plastics like polyethylene or polypropylene.

The investment is justified by its total cost of ownership. Its longevity and low-maintenance nature almost always result in long-term savings in demanding applications.

Machining and Fabrication Nuances

While versatile, the softness of PTFE can make it challenging to machine to extremely tight tolerances. It requires specialized knowledge and tooling to fabricate correctly without introducing internal stresses.

Making the Right Choice for Your Application

Selecting the right material depends entirely on the primary challenge you need to solve.

- If your primary focus is reliability in corrosive environments: PTFE's chemical inertness makes it the definitive choice for seals, linings, and valves in chemical or pharmaceutical processing.

- If your primary focus is reducing energy loss and wear: Its exceptionally low friction is ideal for self-lubricating bearings, slide plates, and non-stick coatings where efficiency is paramount.

- If your primary focus is performance at temperature extremes: PTFE's wide operating range ensures stability in both cryogenic and high-heat applications where other materials would fail.

- If your primary focus is a cost-sensitive, low-stress application: You may need to evaluate if PTFE's performance benefits justify its higher cost compared to less robust engineering plastics.

Ultimately, selecting PTFE is an investment in long-term operational stability and performance where standard materials cannot compete.

Summary Table:

| Property | Benefit | Key Industries |

|---|---|---|

| Chemical Inertness | Resists aggressive acids, bases, and solvents | Chemical Processing, Pharma, Oil & Gas |

| Low Friction | Self-lubricating, reduces wear and energy use | Manufacturing, Automotive, Food Processing |

| Extreme Temperature Range | Stable from -200°C to +260°C | Aerospace, Cryogenics, High-Temp Manufacturing |

| Superior Electrical Insulation | Excellent dielectric properties | Electronics, Telecommunications |

Ready to solve your toughest material challenges with PTFE?

At KINTEK, we specialize in manufacturing high-precision PTFE components—including custom seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication, from prototypes to high-volume orders, ensures you get components that deliver long-term reliability, reduce maintenance costs, and prevent downtime.

Contact us today to discuss how our PTFE solutions can enhance your operational efficiency and performance.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What are the key properties of Teflon (PTFE)? Unlocking Extreme Performance for Demanding Applications

- What are the key components of PTFE? Unlocking the Power of Carbon and Fluorine

- Why are fillers added to PTFE? Enhance Performance for Demanding Applications

- How is Fine Powder PTFE different from Granular PTFE? Choose the Right Material for Your Process

- What are the key characteristics of PTFE? A Guide to Its Extreme Performance

- How does the electronegativity of fluorine affect PTFE's structure? The Key to Its Unmatched Chemical Resistance

- What are the characteristics and uses of bronze-filled PTFE? A Guide to High-Strength PTFE Composites

- What are the key takeaways about PTFE and expanded PTFE? Choosing the Right High-Performance Polymer