At its most fundamental level, Polytetrafluoroethylene (PTFE) is a high-performance fluoropolymer composed of only two elements: carbon and fluorine. This simple chemical foundation gives rise to a unique set of properties, which in turn allows for the creation of a wide array of physical components used across countless industries.

The core concept to grasp is that PTFE's remarkable characteristics—its extreme chemical inertness, non-stick surface, and wide temperature tolerance—are all direct results of its simple, incredibly strong carbon-fluorine molecular structure.

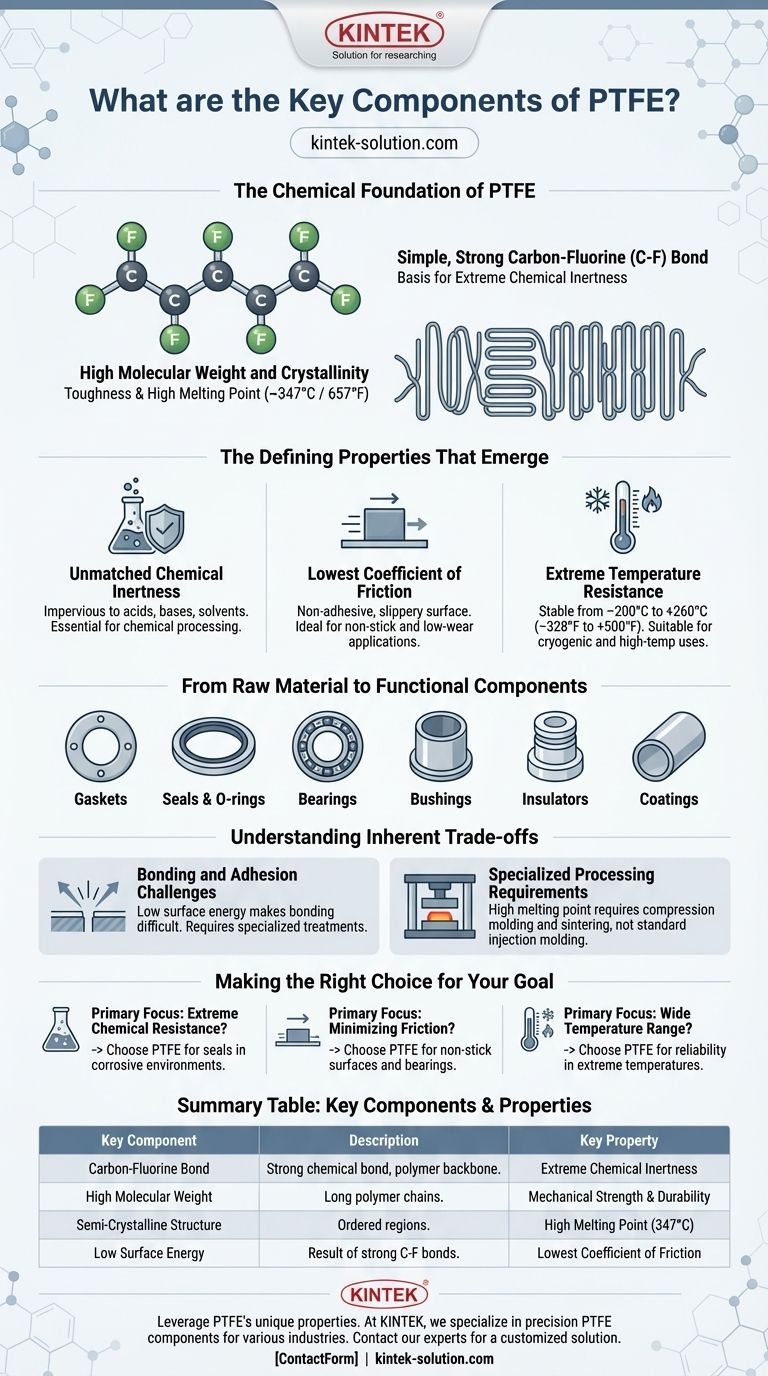

The Chemical Foundation of PTFE

To truly understand PTFE, you must start at the molecular level. Its properties are not random; they are a direct consequence of its chemical makeup.

Carbon and Fluorine: A Simple, Strong Bond

PTFE is a linear polymer with a repeating monomer unit of C2F4. The bond between carbon and fluorine atoms is one of the strongest known in organic chemistry.

This powerful bond shields the carbon backbone from chemical attack, forming the basis for PTFE's legendary inertness.

High Molecular Weight and Crystallinity

PTFE consists of very long polymer chains, giving it a high molecular weight. This contributes significantly to its toughness and mechanical strength.

The material also has a semi-crystalline structure, with ordered regions that provide stability and contribute to its high melting point of around 347°C (657°F).

The Defining Properties That Emerge

The molecular structure of PTFE gives rise to a combination of physical and chemical properties that are unmatched by any other single material.

Unmatched Chemical Inertness

Because of its strong C-F bonds, PTFE is virtually impervious to chemical attack. It can withstand exposure to the most aggressive acids, bases, and solvents without degrading.

This makes it an essential material for chemical processing equipment, pipes, and container linings.

The Lowest Coefficient of Friction

PTFE has the lowest coefficient of friction of any known solid material. This gives it an exceptionally non-adhesive and "slippery" surface.

This property is the reason it is used for non-stick coatings, as well as for high-performance bearings, piston rings, and seals where low wear is critical.

Extreme Temperature Resistance

The material is highly flexible and stable across an exceptionally wide temperature range, performing reliably from –200°C to +260°C (–328°F to +500°F).

This allows it to be used in cryogenic applications as well as in high-temperature industrial processes.

Excellent Dielectric Properties

PTFE is an outstanding electrical insulator. Its resistance to electrical current makes it a preferred choice for high-frequency wire and cable insulation.

From Raw Material to Functional Components

The unique properties of PTFE allow it to be machined and molded into a vast array of physical components that solve specific engineering challenges.

Common Machined Shapes

PTFE is easily machined into precise shapes for demanding applications.

Common components include gaskets, seals, V-rings, O-rings, bearings, bushings, piston rings, washers, and insulators.

Versatility in Application

Beyond discrete parts, its properties make it suitable for surface coatings, pump components like AODD balls, and spacers in complex assemblies. Its compliance with FDA standards also allows for its use in food and medical applications.

Understanding the Inherent Trade-offs

While its properties are remarkable, they also introduce specific limitations that are critical to understand for successful application.

Bonding and Adhesion Challenges

The very property that makes PTFE non-stick—its low surface energy—also makes it extremely difficult to bond to other materials.

Specialized surface treatments, such as chemical etching, are required to create a bondable surface, adding complexity and cost to the manufacturing process.

Specialized Processing Requirements

PTFE's high melting point means it cannot be processed using conventional thermoplastic techniques like injection molding.

It requires specialized compression molding and sintering (a high-temperature heating process) to form solid shapes, which can be slower and more complex than other polymer processing methods.

Making the Right Choice for Your Goal

Understanding the core components of PTFE—both its chemistry and its resulting properties—allows you to apply it effectively.

- If your primary focus is extreme chemical resistance: PTFE's inertness makes it the definitive choice for seals, linings, and components in corrosive environments.

- If your primary focus is minimizing friction: Its incredibly low coefficient of friction makes it the top choice for non-stick surfaces and low-wear bearings.

- If your primary focus is performance across a wide temperature range: PTFE maintains its integrity from cryogenic lows to industrial highs, ensuring reliability where other materials fail.

Ultimately, recognizing how PTFE's simple two-element chemistry creates its powerful, multifaceted performance is the key to leveraging it correctly.

Summary Table:

| Key Component | Description | Key Property |

|---|---|---|

| Carbon-Fluorine Bond | Strong chemical bond forming the polymer backbone. | Extreme Chemical Inertness |

| High Molecular Weight | Long polymer chains contributing to toughness. | Mechanical Strength & Durability |

| Semi-Crystalline Structure | Ordered regions within the polymer. | High Melting Point (347°C / 657°F) |

| Low Surface Energy | Result of the strong C-F bonds. | Lowest Coefficient of Friction |

Leverage PTFE's unique properties for your most demanding applications. At KINTEK, we specialize in precision manufacturing of PTFE components—from custom seals and liners to complex labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you need prototypes or high-volume production, our expertise ensures optimal performance for corrosive, high-temperature, or low-friction environments. Contact our experts today to discuss your specific requirements and receive a customized solution.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability