In short, fillers are added to PTFE to overcome its natural softness and tendency to deform under pressure. While virgin PTFE is known for its low friction and chemical inertness, it lacks the mechanical strength for many demanding applications. Fillers act as a reinforcing agent, dramatically improving properties like wear resistance, compressive strength, and thermal conductivity.

Adding a filler to PTFE fundamentally transforms it from a soft, non-stick material into a durable, high-performance engineering plastic. The specific filler is chosen to selectively enhance the exact properties required by the application, such as load-bearing capacity or heat dissipation.

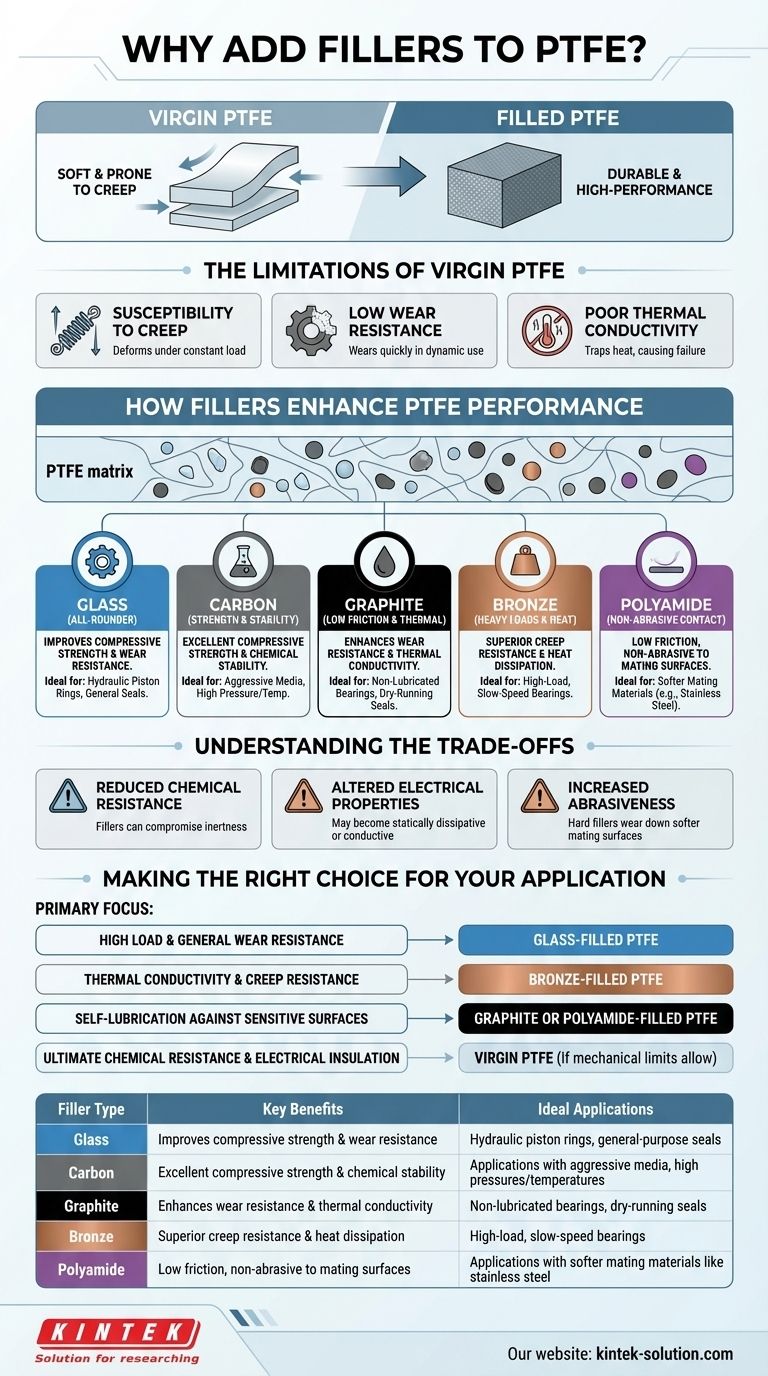

The Limitations of Virgin PTFE

To understand why fillers are necessary, we must first recognize the inherent weaknesses of Polytetrafluoroethylene (PTFE) in its pure, or "virgin," state.

Susceptibility to Creep

Virgin PTFE is susceptible to creep, which is the tendency of a solid material to move slowly or deform permanently under the influence of persistent mechanical stress.

Under a heavy or constant load, a component made from virgin PTFE will gradually lose its shape, compromising the integrity of a seal or bearing.

Low Wear Resistance

While PTFE has an exceptionally low coefficient of friction, this does not mean it is resistant to abrasion.

In applications with repetitive motion, virgin PTFE can wear down quickly, generating debris and leading to premature failure.

Poor Thermal Conductivity

PTFE is an excellent thermal insulator. In high-speed or high-friction applications, this becomes a liability.

Heat generated by friction cannot dissipate effectively, which can cause the material to soften, expand, and fail.

How Fillers Enhance PTFE Performance

By blending specific materials into the PTFE matrix, engineers can precisely tune its properties to meet demanding operational conditions.

Glass: The All-Rounder

Glass fiber is the most common filler used in PTFE.

It significantly improves compressive strength and wear resistance, making it a default choice for components like hydraulic piston rings and general-purpose seals.

Carbon: For Strength and Chemical Stability

Carbon, often in fiber form, provides excellent compressive strength and is more resistant to harsh chemicals than glass.

This makes carbon-filled PTFE ideal for applications involving aggressive media, high pressures, and high temperatures.

Graphite: For Low Friction and Thermal Management

Graphite enhances both wear resistance and thermal conductivity.

It also imparts self-lubricating properties, making graphite-filled PTFE a top choice for non-lubricated or dry-running applications like bearings and seals.

Bronze: For Heavy Loads and Heat Dissipation

Bronze fillers provide the best creep resistance and thermal conductivity of all common fillers.

This combination is perfect for high-load, slow-speed applications where the material must maintain its shape and dissipate frictional heat effectively.

Polyamide: For Non-Abrasive Contact

Polyamide has a low friction coefficient and is much less abrasive than glass.

This makes it an excellent choice for applications where the PTFE component runs against softer materials like stainless steel, aluminum, or brass, as it minimizes wear on the mating surface.

Understanding the Trade-offs of Filled PTFE

While fillers provide substantial benefits, they also introduce critical trade-offs that must be considered during material selection.

Reduced Chemical Resistance

The primary advantage of virgin PTFE is its near-universal chemical inertness.

Adding a filler material can compromise this property. The filler itself may be susceptible to chemical attack from media that virgin PTFE would easily resist.

Altered Electrical Properties

Virgin PTFE is one of the best electrical insulators available.

Adding conductive fillers like carbon, graphite, or metals will dramatically change these properties, potentially making the material statically dissipative or even conductive.

Increased Abrasiveness

Hard fillers, particularly glass, can be abrasive to the surfaces they run against.

This is a critical consideration in dynamic applications, as a glass-filled seal could prematurely wear down a softer metal shaft.

Making the Right Choice for Your Application

Selecting the correct filled PTFE compound is a matter of aligning the material's properties with the primary demands of your application.

- If your primary focus is high load and general wear resistance: Glass-filled PTFE is the most common and cost-effective solution.

- If your primary focus is thermal conductivity and creep resistance: Bronze-filled PTFE is superior for heavy-duty bearings and load-bearing components.

- If your primary focus is self-lubrication against sensitive surfaces: Graphite or polyamide-filled PTFE will minimize wear on mating parts in dry-running systems.

- If your primary focus is ultimate chemical resistance and electrical insulation: Virgin PTFE remains the best choice, provided its mechanical limitations are acceptable.

By understanding these fundamentals, you can select a material engineered to succeed in your specific operational environment.

Summary Table:

| Filler Type | Key Benefits | Ideal Applications |

|---|---|---|

| Glass | Improves compressive strength & wear resistance | Hydraulic piston rings, general-purpose seals |

| Carbon | Excellent compressive strength & chemical stability | Applications with aggressive media, high pressures/temperatures |

| Graphite | Enhances wear resistance & thermal conductivity | Non-lubricated bearings, dry-running seals |

| Bronze | Superior creep resistance & heat dissipation | High-load, slow-speed bearings |

| Polyamide | Low friction, non-abrasive to mating surfaces | Applications with softer mating materials like stainless steel |

Need high-performance PTFE components tailored to your specific requirements? KINTEK specializes in manufacturing precision PTFE seals, liners, labware, and custom components for semiconductor, medical, laboratory, and industrial applications. We offer custom fabrication from prototypes to high-volume orders, ensuring your filled PTFE parts deliver optimal performance in demanding environments. Contact us today to discuss your project and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What is the dispersion method of producing PTFE and what are its products? Ideal for Thin Coatings and Films

- Which countries are the major producers of PTFE? Navigating the Concentrated Global Supply Chain

- What are the different types of Teflon coatings and their features? Choose the Right Fluoropolymer for Your Application

- What raw materials are used to create Teflon? From Simple Minerals to High-Performance PTFE

- What are the environmental and safety considerations for Teflon and UHMW? Ensure Safe Material Selection

- What are the benefits of using Teflon in fiberglass? Achieve Unmatched Durability and Chemical Resistance

- Why is PTFE's low friction coefficient significant? Unlock Superior Efficiency and Longevity

- How does PTFE perform in chemically aggressive applications? Unmatched Chemical Resistance for Demanding Industries