In short, Polytetrafluoroethylene (PTFE), commonly known as Teflon, is a high-performance fluoropolymer defined by a unique combination of extreme properties. Its key characteristics are an exceptionally low coefficient of friction, near-total chemical inertness, high-temperature stability, and excellent electrical insulation. These traits make it a "problem-solver" material for demanding engineering environments.

The true value of PTFE isn't found in any single property, but in its rare combination of capabilities. It is a material of extremes that simultaneously resists chemical attack, heat, friction, and electrical current, making it invaluable where other materials fail.

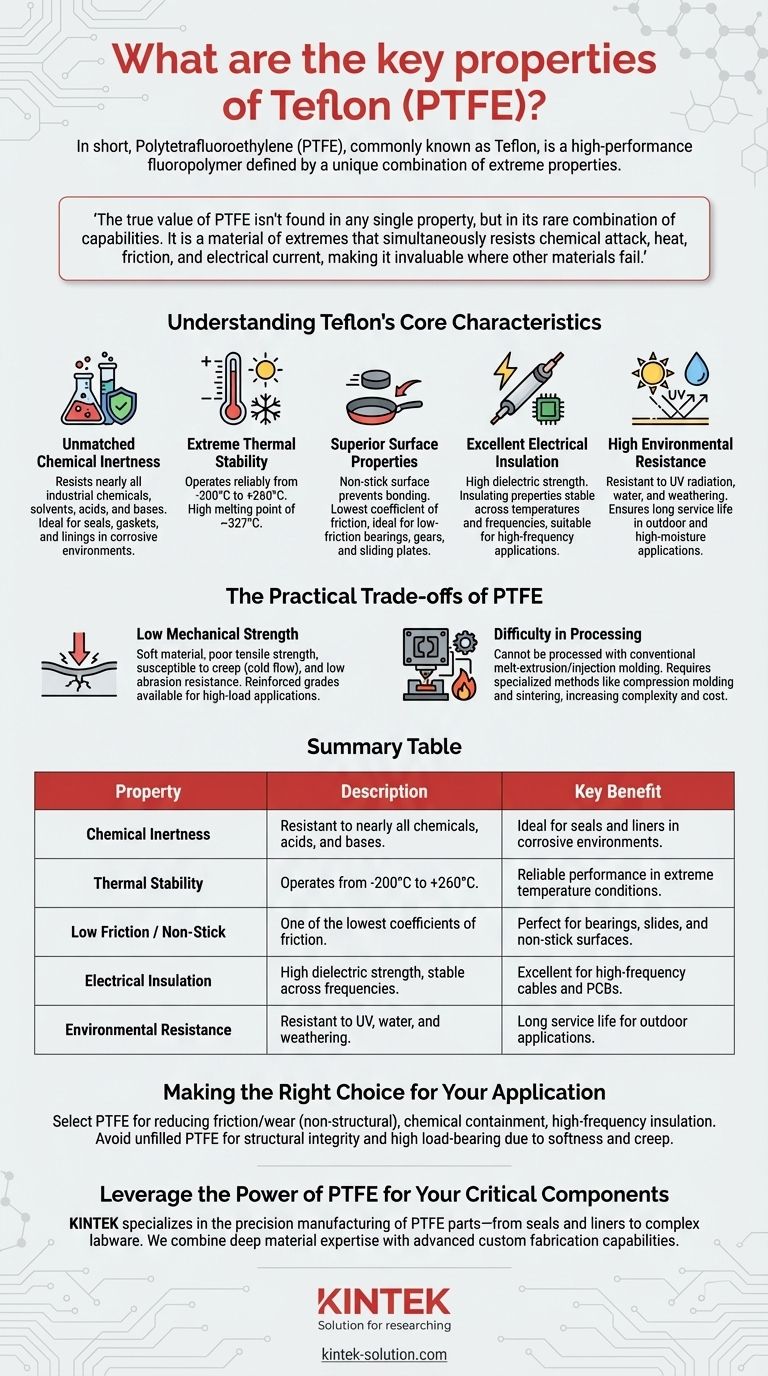

Understanding Teflon's Core Characteristics

To effectively apply PTFE, it's crucial to understand how its distinct properties create value in different contexts. These characteristics stem directly from its molecular structure: a strong carbon-fluorine bond.

Unmatched Chemical Inertness

PTFE exhibits remarkable resistance to nearly all industrial chemicals, solvents, acids, and bases. This makes it an ideal material for seals, gaskets, and linings in corrosive environments.

Its surface is non-reactive, which also contributes to its suitability for use in the food and medical industries.

Extreme Thermal Stability

The material operates reliably across an exceptionally wide temperature range, typically from -200°C to +260°C (-328°F to +500°F).

While it can withstand these temperatures for extended periods, it has a high melting point of approximately 327°C (621°F).

Superior Surface Properties

PTFE is famous for its non-stick or anti-adhesive surface. This low surface energy prevents other materials, from dirt and contaminants to sticky foods, from bonding to it.

It also possesses one of the lowest coefficients of friction of any known solid. This extreme lubricity makes it a first-choice material for low-friction bearings, gears, and sliding plates where "stick-slip" motion must be avoided.

Excellent Electrical Insulation

PTFE is an outstanding electrical insulator with a high dielectric strength. Its insulating properties remain stable across a wide range of temperatures and frequencies.

This consistency makes it highly valuable for high-frequency applications, such as in coaxial cables and printed circuit boards (PCBs).

High Environmental Resistance

The material is highly resistant to environmental factors. It does not absorb water and is virtually immune to degradation from UV radiation and weathering.

This durability ensures a long service life for components used in outdoor or high-moisture applications.

The Practical Trade-offs of PTFE

While its properties are exceptional, PTFE is not the solution for every problem. An objective assessment must include its inherent limitations, which are primarily mechanical.

Low Mechanical Strength

PTFE is a relatively soft material. It has poor tensile strength and is susceptible to creep, also known as "cold flow," where the material deforms under sustained pressure.

It also has low abrasion and wear resistance compared to other engineering plastics. For high-load mechanical applications, it is often reinforced with fillers like glass, carbon, or bronze.

Difficulty in Processing

Unlike common thermoplastics, PTFE cannot be processed using conventional melt-extrusion or injection molding techniques due to its extremely high melt viscosity.

It must be processed using specialized methods like compression molding and sintering, which can increase manufacturing complexity and cost.

Making the Right Choice for Your Application

Selecting the right material requires matching its properties to your primary goal. Use these guidelines to determine if PTFE is the optimal choice for your project.

- If your primary focus is reducing friction and wear: PTFE is an excellent choice for non-structural, low-load applications like slide bearings, but consider filled grades for higher mechanical demands.

- If your primary focus is chemical containment: Its near-total chemical inertness makes it one of the best materials available for seals, liners, and tubing in aggressive chemical environments.

- If your primary focus is high-frequency electrical insulation: PTFE's stable and low dielectric constant is ideal for high-performance cables, connectors, and substrates.

- If your primary focus is structural integrity and high load-bearing: Unfilled PTFE is likely the wrong choice due to its softness and tendency to creep; look to other engineering polymers or filled PTFE grades.

Understanding both the unparalleled strengths and the distinct weaknesses of PTFE is the key to leveraging it effectively in any design.

Summary Table:

| Property | Description | Key Benefit |

|---|---|---|

| Chemical Inertness | Resistant to nearly all chemicals, acids, and bases. | Ideal for seals and liners in corrosive environments. |

| Thermal Stability | Operates from -200°C to +260°C. | Reliable performance in extreme temperature conditions. |

| Low Friction / Non-Stick | One of the lowest coefficients of friction. | Perfect for bearings, slides, and non-stick surfaces. |

| Electrical Insulation | High dielectric strength, stable across frequencies. | Excellent for high-frequency cables and PCBs. |

| Environmental Resistance | Resistant to UV, water, and weathering. | Long service life for outdoor applications. |

Leverage the Power of PTFE for Your Critical Components

Understanding PTFE's properties is the first step. Implementing them effectively in a custom component is the next. KINTEK specializes in the precision manufacturing of PTFE parts—from seals and liners to complex labware—for the semiconductor, medical, laboratory, and industrial sectors.

We combine deep material expertise with advanced custom fabrication capabilities, guiding your project from prototype to high-volume production. Ensure your application benefits from PTFE's full potential.

Contact KINTEK today to discuss your specific requirements and get a quote for your custom PTFE solution.

Visual Guide

Related Products

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What environmental resistances does PTFE offer? Unmatched Durability for Harsh Conditions

- When was PTFE discovered and developed? The Accidental Invention That Changed Industries

- What are the similarities between PTFE and RPTFE? Unlocking the Core Fluoropolymer Identity

- What is PTFE and what class of plastics does it belong to? A Guide to High-Performance Fluoropolymers

- What is PTFE commonly known as and what type of material is it? A Guide to High-Performance PTFE Properties