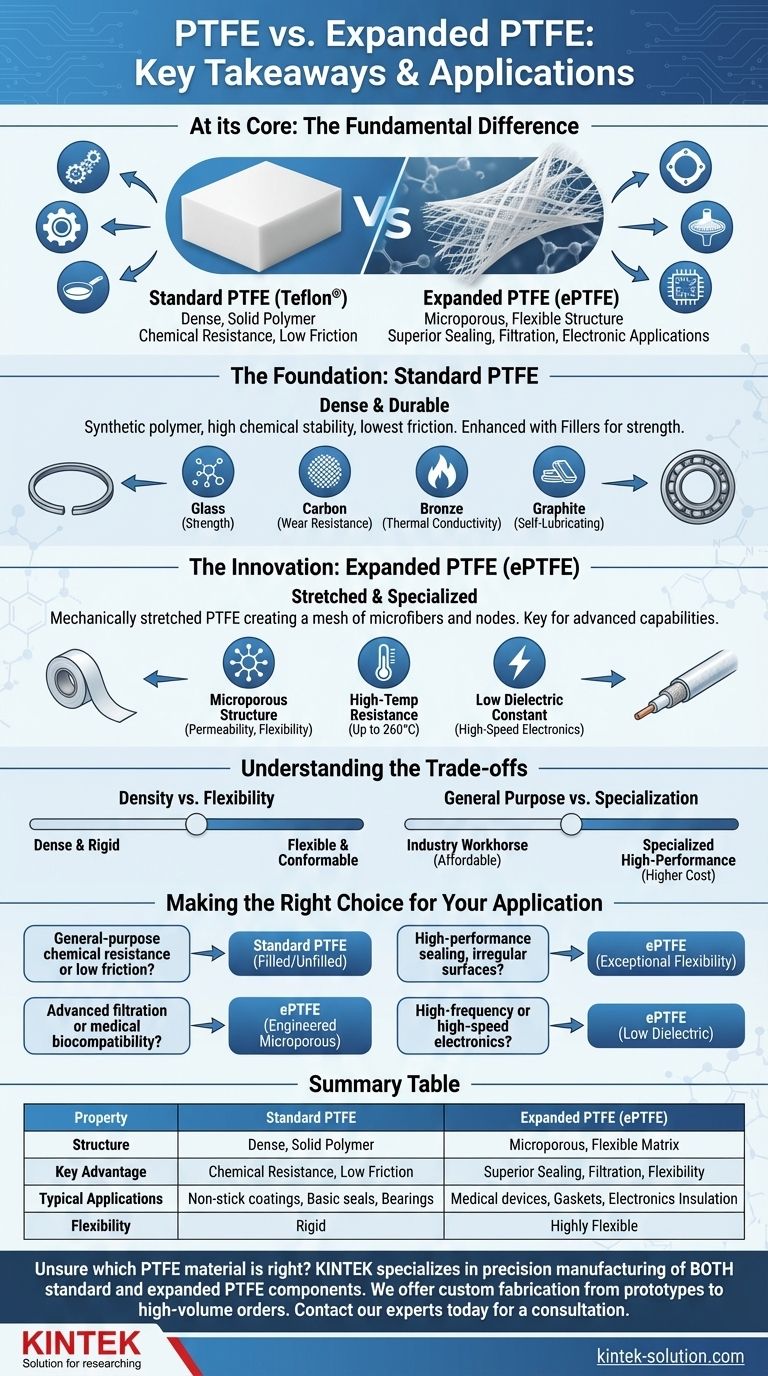

At its core, Polytetrafluoroethylene (PTFE) is a highly stable and chemically resistant solid polymer, widely known by the brand name Teflon. Expanded PTFE (ePTFE) is a modified version of this same material, physically stretched to create a microporous, flexible structure that grants it a unique set of high-performance capabilities.

The fundamental difference lies in their structure: standard PTFE is a dense, solid material valued for chemical resistance and low friction, while ePTFE is a pliable, porous material engineered for superior sealing, filtration, and specialized electronic applications.

The Foundation: Understanding Standard PTFE

Standard PTFE is a versatile fluoropolymer that serves as the basis for many industrial and commercial applications. Its dense molecular structure is the source of its most well-known properties.

### What is PTFE?

PTFE, or Polytetrafluoroethylene, is a synthetic polymer renowned for its exceptional chemical stability and corrosion resistance. It is a solid material with one of the lowest coefficients of friction of any solid.

This inherent inertness and lubricity make it a default choice for applications requiring a non-stick, non-reactive surface.

### The Role of Fillers

While base PTFE is highly effective, its mechanical properties like strength and wear resistance can be significantly enhanced with fillers. These additives are mixed into the PTFE resin before it is processed.

Common fillers include:

- Glass: The most common filler, used to improve strength and wear resistance, particularly in components like hydraulic piston rings.

- Carbon: Offers excellent wear resistance and reduces deformation under load.

- Bronze: Provides superior thermal conductivity and is often used in bearings and piston rings.

- Graphite: A self-lubricating filler that reduces initial wear.

The Innovation: Expanded PTFE (ePTFE)

ePTFE begins as standard PTFE but undergoes a mechanical expansion process. This creates a fundamentally different material with a unique physical structure.

### How ePTFE is Different

The expansion process creates a mesh structure of microfibers connected by nodes, resulting in countless microscopic pores. This gives the material its characteristic flexibility and permeability while retaining the chemical inertness of the original PTFE.

This microporous structure is the key to ePTFE's advanced capabilities, allowing it to be engineered with varying levels of porosity (low, medium, and high density) for specific needs.

### Key Properties and Applications

While sharing PTFE's high-temperature resistance (up to 260°C) and chemical inertness, ePTFE offers several distinct advantages.

It provides high linear strength, excellent radial expansion, and watertightness at low pressure. Its flexibility makes it exceptionally easy to cut, shape, and install, especially as a sealing tape or gasket for irregular or wide flange gaps.

Because of these properties, ePTFE is critical in demanding fields such as medical devices (due to its biocompatibility), high-performance filters, chemical pipe flanges, and as an insulator in high-speed electronics.

Understanding the Trade-offs

Choosing between PTFE and ePTFE requires understanding the balance between performance requirements, environmental conditions, and cost.

### Density vs. Flexibility

Standard PTFE is a dense, relatively rigid material. Its strength often comes from its solid form or the addition of fillers.

ePTFE is, by design, less dense and highly flexible. This makes it a superior sealing material for conforming to uneven surfaces but means it serves a different mechanical purpose than solid, load-bearing PTFE components.

### General Purpose vs. Specialization

PTFE is the industry workhorse for a vast range of applications, from non-stick coatings to basic insulators and seals. It is widely available and generally more affordable.

ePTFE is a specialized, high-performance material. Its higher cost is justified in applications where its unique properties—like controlled porosity, extreme flexibility, or low dielectric constant for high-frequency circuits—are non-negotiable.

Making the Right Choice for Your Application

Your final decision depends entirely on the specific demands of your project. The two materials solve different problems, even though they share a common chemical origin.

- If your primary focus is general-purpose chemical resistance or low-friction surfaces: Standard PTFE, often with appropriate fillers for mechanical strength, is the most robust and cost-effective solution.

- If your primary focus is high-performance sealing, especially on irregular surfaces: ePTFE is the superior choice due to its exceptional flexibility and ability to conform under pressure.

- If your primary focus is advanced filtration or medical biocompatibility: The engineered microporous structure of ePTFE makes it the only viable option.

- If your primary focus is high-frequency or high-speed electronics: ePTFE's low dielectric constant is critical for maintaining signal integrity, justifying its higher cost.

Ultimately, selecting the correct material requires matching its distinct physical structure to the specific challenges of your application.

Summary Table:

| Property | Standard PTFE | Expanded PTFE (ePTFE) |

|---|---|---|

| Structure | Dense, solid polymer | Microporous, flexible matrix |

| Key Advantage | Chemical resistance, low friction | Superior sealing, filtration, flexibility |

| Typical Applications | Non-stick coatings, basic seals, bearings | Medical devices, high-performance gaskets, electronics insulation |

| Flexibility | Rigid | Highly flexible and conformable |

Unsure which PTFE material is right for your project?

KINTEK specializes in the precision manufacturing of both standard PTFE and expanded PTFE components. Whether you need the robust chemical resistance of filled PTFE seals or the advanced performance of ePTFE gaskets for demanding semiconductor, medical, or industrial applications, our expertise ensures you get the optimal solution.

We offer custom fabrication from prototypes to high-volume orders, guaranteeing the performance and reliability your project demands.

Contact our experts today for a consultation and let us help you select and manufacture the perfect PTFE component.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech