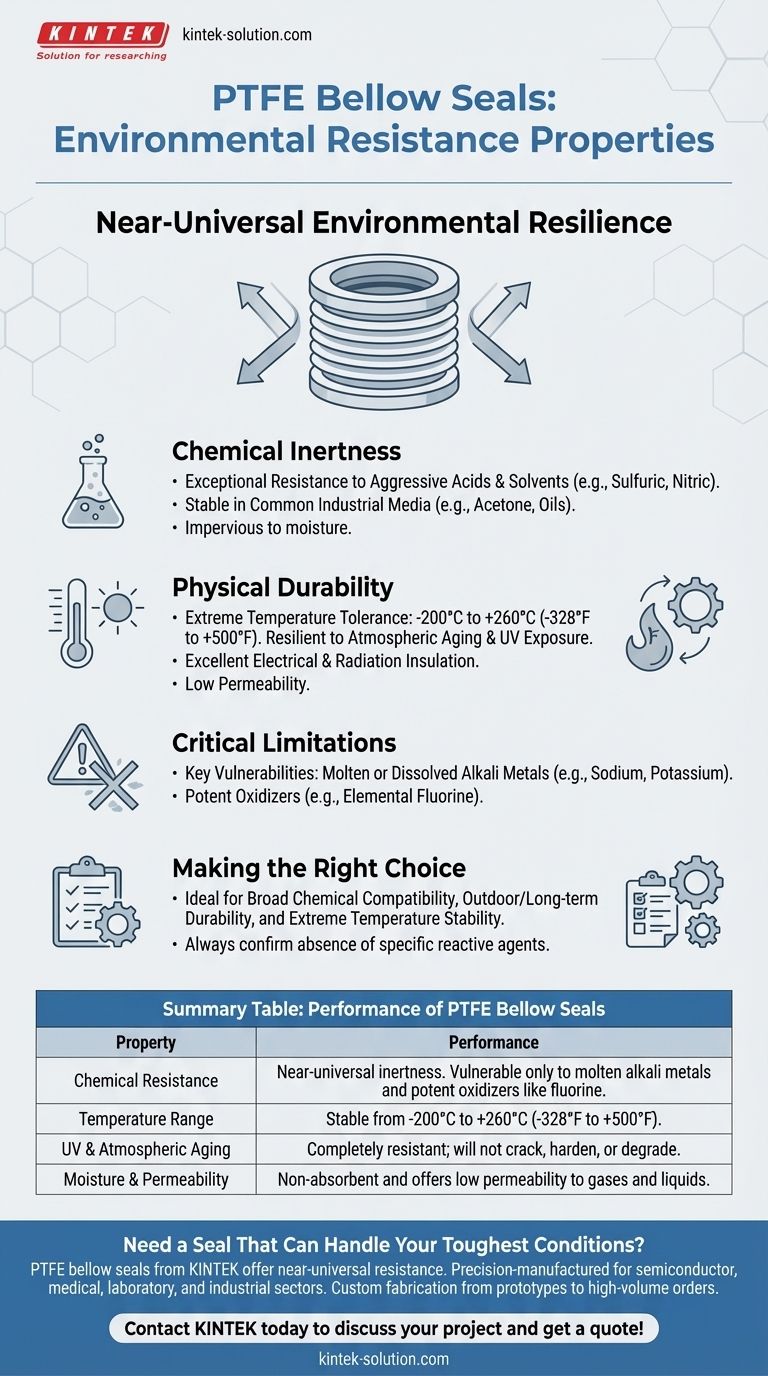

At its core, Polytetrafluoroethylene (PTFE) provides near-universal environmental resistance. PTFE bellow seals are exceptionally resilient against a vast range of environmental factors. They exhibit near-total chemical inertness, are unaffected by atmospheric aging, UV light, or moisture, and maintain their integrity across an extremely wide temperature spectrum.

While PTFE provides an unparalleled defense against most chemicals and environmental conditions, its primary vulnerability lies with a very specific class of reactive agents, such as molten alkali metals and potent oxidizers like fluorine. Understanding this critical exception is key to its successful application.

A Breakdown of PTFE's Chemical Inertness

The primary reason engineers specify PTFE is its remarkable ability to withstand chemical attack. This property is not just a minor feature; it is a defining characteristic of the material.

Resistance to Aggressive Acids and Solvents

PTFE is nearly impervious to chemical corrosion. It remains completely unchanged even when boiled in concentrated acids like sulfuric, nitric, or hydrochloric acid.

Furthermore, it has almost no solubility in any common solvent at temperatures below 300°C (572°F), preventing chemical absorption that could lead to swelling or degradation.

Stability in Common Industrial Media

The material demonstrates exceptional stability in a wide range of industrial fluids. This includes common substances like acetone, chloroform, oils, tallow, and even sodium peroxide.

Its performance is further enhanced by the fact that it does not absorb moisture, ensuring consistent dimensions and properties in humid or submerged environments.

Performance in Demanding Physical Environments

Beyond chemical stability, PTFE bellow seals are engineered to survive in physically harsh conditions where lesser materials would quickly fail.

Extreme Temperature Tolerance

PTFE maintains its properties across an exceptionally wide service temperature range, from –200° C to +260° C (–328° F to +500° F).

This allows it to be used reliably in everything from cryogenic applications to high-heat industrial processes without becoming brittle or degrading.

Resilience to Atmospheric and UV Exposure

The material is completely stable against atmospheric aging, oxygen, and UV light.

This makes PTFE bellow seals ideal for outdoor equipment or any application with long-term exposure to the elements, as they will not crack, harden, or lose performance over time.

Electrical and Radiation Insulation

PTFE is an excellent electrical insulator, with a very high volume resistance that is unaffected by environmental conditions or frequency. It also demonstrates strong resistance to radiation damage.

Its low permeability means it effectively resists the passage of gases and liquids, a critical feature for any sealing component.

Understanding the Critical Limitations

No material is perfect. A technical advisor's role is to clarify not just the strengths but also the specific weaknesses. For PTFE, these limitations are few but absolute.

The Alkali Metal Exception

PTFE will be attacked and degraded by molten or dissolved alkali metals, such as liquid sodium or potassium. This is one of its most well-known and critical vulnerabilities.

Vulnerability to Potent Oxidizers

The material is not resistant to elemental fluorine and other extremely potent oxidizing agents.

These highly reactive chemicals are among the very few that can break down the stable fluoropolymer structure of PTFE.

Making the Right Choice for Your Application

To determine if a PTFE bellow seal is the correct choice, match its specific resistance profile to your operational environment.

- If your primary focus is broad chemical compatibility: PTFE is an ideal choice for systems handling aggressive acids, solvents, and oils, as long as you can confirm the absence of molten alkali metals or elemental fluorine.

- If your primary focus is outdoor or long-term durability: Its complete immunity to UV, ozone, and moisture makes PTFE a superior material for applications requiring sustained performance without aging or degradation.

- If your primary focus is extreme temperature stability: The material’s vast operating range from cryogenic lows to high heat ensures reliable sealing where other elastomers would fail.

Ultimately, a PTFE bellow seal provides a nearly foolproof solution for most environmental challenges, provided you operate within its well-defined chemical boundaries.

Summary Table:

| Property | Performance of PTFE Bellow Seals |

|---|---|

| Chemical Resistance | Near-universal inertness to acids, solvents, and industrial media. Vulnerable only to molten alkali metals and potent oxidizers like fluorine. |

| Temperature Range | Stable from -200°C to +260°C (-328°F to +500°F), suitable for cryogenic to high-heat applications. |

| UV & Atmospheric Aging | Completely resistant; will not crack, harden, or degrade from exposure. |

| Moisture & Permeability | Non-absorbent and offers low permeability to gases and liquids. |

Need a Seal That Can Handle Your Toughest Conditions?

PTFE bellow seals from KINTEK offer the near-universal environmental resistance your application demands. Whether you're in the semiconductor, medical, laboratory, or industrial sector, our precision-manufactured PTFE components—including custom seals, liners, and labware—are engineered for reliability in aggressive chemical and extreme temperature environments.

We specialize in custom fabrication, from prototypes to high-volume orders, ensuring a perfect fit for your specific needs.

Contact KINTEK today to discuss your project and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What chemical resistance properties do PTFE envelope gaskets offer? Achieve Universal Sealing for Aggressive Chemicals

- What speed capability do PTFE oil seals have? Handle High-Speeds up to 30 m/s

- What materials are used for jacket profiles and springs in PTFE seals? A Guide to Material Selection

- How does the PTFE oil seal's design handle shaft eccentricity? Achieve Reliable Sealing Under Dynamic Conditions

- How does PTFE Liner help in eliminating stick-slip in cable applications? Achieve Smooth, Reliable Motion

- How do PTFE and nylon differ in terms of water interactivity? Key Differences for Component Stability

- Why are PTFE extruded rods used in chemical processing equipment? For Superior Chemical Resistance and Purity

- What makes Teflon plastic sheets versatile across industries? The Ultimate High-Performance Solution