PTFE oil seals are specifically engineered for high-speed applications, capable of operating at surface speeds up to 30 m/s (approximately 6,000 ft/min), with certain designs reaching even higher velocities. This performance is not accidental; it is a direct consequence of PTFE's unique material characteristics, which allow it to manage the intense heat and friction generated by rapidly rotating shafts.

The true value of a PTFE seal isn't just its maximum speed rating, but its ability to maintain integrity under the extreme conditions that high speeds create. Its low-friction nature and high-temperature resistance work in tandem to prevent the very heat buildup that causes traditional seals to fail.

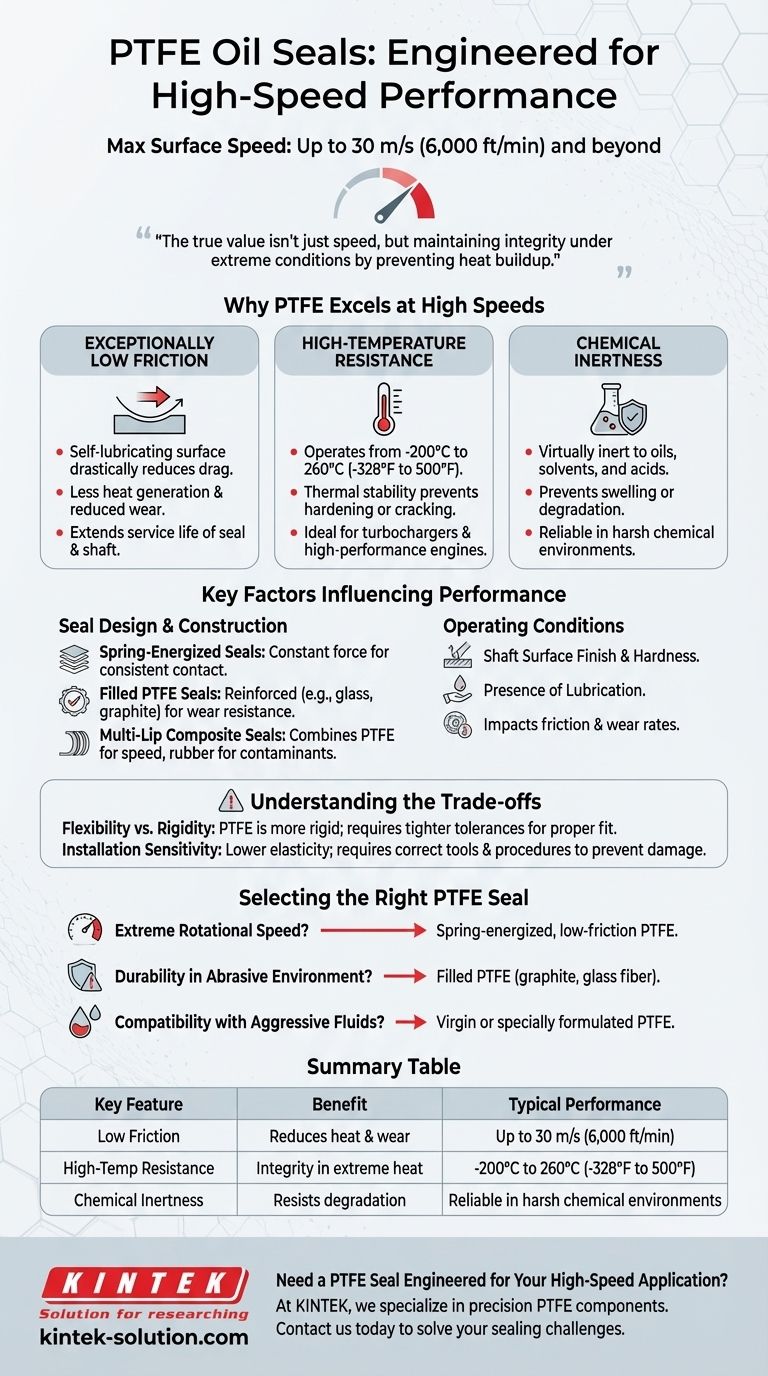

Why PTFE Excels at High Speeds

The superior performance of PTFE seals in demanding, high-velocity environments stems from a combination of core material properties. These characteristics directly address the primary challenges of rotational sealing.

Exceptionally Low Friction

PTFE has one of the lowest coefficients of friction of any solid material. This self-lubricating, non-stick surface drastically reduces the drag between the seal lip and the rotating shaft.

This property directly translates to less frictional heat generation, which is the principal cause of seal degradation and failure in high-speed applications. It also reduces wear on both the seal and the shaft, extending the service life of the entire assembly.

High-Temperature Resistance

High rotational speeds invariably generate significant heat. PTFE seals are designed to operate effectively across a vast temperature range, typically from -200°C to 260°C (-328°F to 500°F).

This thermal stability ensures the seal material does not harden, crack, or lose its sealing properties when exposed to the high temperatures common in turbochargers, high-performance engines, and industrial gearboxes.

Chemical Inertness

In many applications, from chemical processing to automotive transmissions, seals are exposed to aggressive oils, solvents, or acids.

PTFE is virtually inert to most chemicals. This resistance prevents the material from swelling, softening, or degrading, ensuring a reliable seal even in harsh chemical environments.

Key Factors Influencing Performance

The maximum achievable speed of a PTFE seal is not a fixed number but is influenced by the specific design of the seal and the conditions under which it operates.

Seal Design and Construction

Not all PTFE seals are created equal. Different designs are optimized for different challenges.

- Spring-Energized Seals: These incorporate a stainless steel spring to provide a constant, energized force on the sealing lip. This ensures consistent contact with the shaft, even with variations in pressure or temperature.

- Filled PTFE Seals: The base PTFE material is often reinforced with fillers like glass fiber, graphite, or bronze powder. These additives enhance properties like wear resistance, creep resistance, and thermal conductivity.

- Multi-Lip Composite Seals: These advanced designs may combine a PTFE sealing lip for high-speed contact with a secondary rubber or polyurethane lip to protect against dust and external contaminants.

Operating Conditions

The application environment plays a critical role in seal performance and longevity. Factors such as shaft surface finish, hardness, and the presence of lubrication directly impact the friction and wear rates at the sealing interface.

Understanding the Trade-offs

While PTFE offers exceptional performance, it is essential to understand its specific characteristics compared to traditional elastomeric (rubber) seals.

Flexibility vs. Rigidity

PTFE is a more rigid material than rubber. While it has enough flexibility to conform to shafts, it is less forgiving of imperfections.

This means that achieving a reliable seal often requires tighter tolerances on both the shaft and the housing bore to ensure proper fit and function.

Installation Sensitivity

Due to its lower elasticity, a PTFE seal lip can be damaged during installation if proper care is not taken.

Using correct installation tools and procedures is critical to prevent nicks or deformation of the sealing edge, which would compromise its performance from the start.

Selecting the Right PTFE Seal for Your Application

Choosing the optimal seal requires matching the design to the primary demands of your equipment.

- If your primary focus is extreme rotational speed: Prioritize a spring-energized design with a low-friction PTFE compound to ensure consistent sealing force and minimal heat generation.

- If your primary focus is durability in an abrasive environment: Choose a filled PTFE seal, reinforced with materials like graphite or glass fiber, to significantly improve wear resistance.

- If your primary focus is compatibility with aggressive fluids: Select a seal made from a virgin or specially formulated PTFE compound known for its broad chemical inertness, common in chemical and pharmaceutical equipment.

Ultimately, recognizing that a PTFE seal's speed capability is a function of its thermal and frictional properties empowers you to select a solution engineered to thrive in your specific high-performance environment.

Summary Table:

| Key Feature | Benefit | Typical Performance |

|---|---|---|

| Low Friction | Reduces heat generation, extends seal & shaft life | Enables speeds up to 30 m/s (6,000 ft/min) |

| High-Temp Resistance | Maintains integrity in extreme heat | Operates from -200°C to 260°C (-328°F to 500°F) |

| Chemical Inertness | Resists degradation from oils, solvents, acids | Reliable performance in harsh chemical environments |

Need a PTFE Seal Engineered for Your High-Speed Application?

At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you need a standard solution or a custom-fabricated seal for prototypes or high-volume orders, our expertise ensures optimal performance under extreme conditions.

Contact us today to discuss how our high-performance PTFE seals can solve your sealing challenges and enhance your equipment's reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application