At its core, a PTFE liner eliminates stick-slip by leveraging the material's exceptionally low coefficient of friction. This property nearly erases the difference between static (sticking) friction and kinetic (sliding) friction, preventing the jerking motion that defines stick-slip. Combined with its high abrasion resistance, this ensures smooth, predictable cable movement and a significantly longer product lifecycle.

The core problem of stick-slip isn't just about jerky motion; it's a fundamental issue of control, precision, and premature wear. A PTFE liner solves this by creating a permanently lubricated, ultra-low-friction pathway, ensuring cables operate with predictable smoothness.

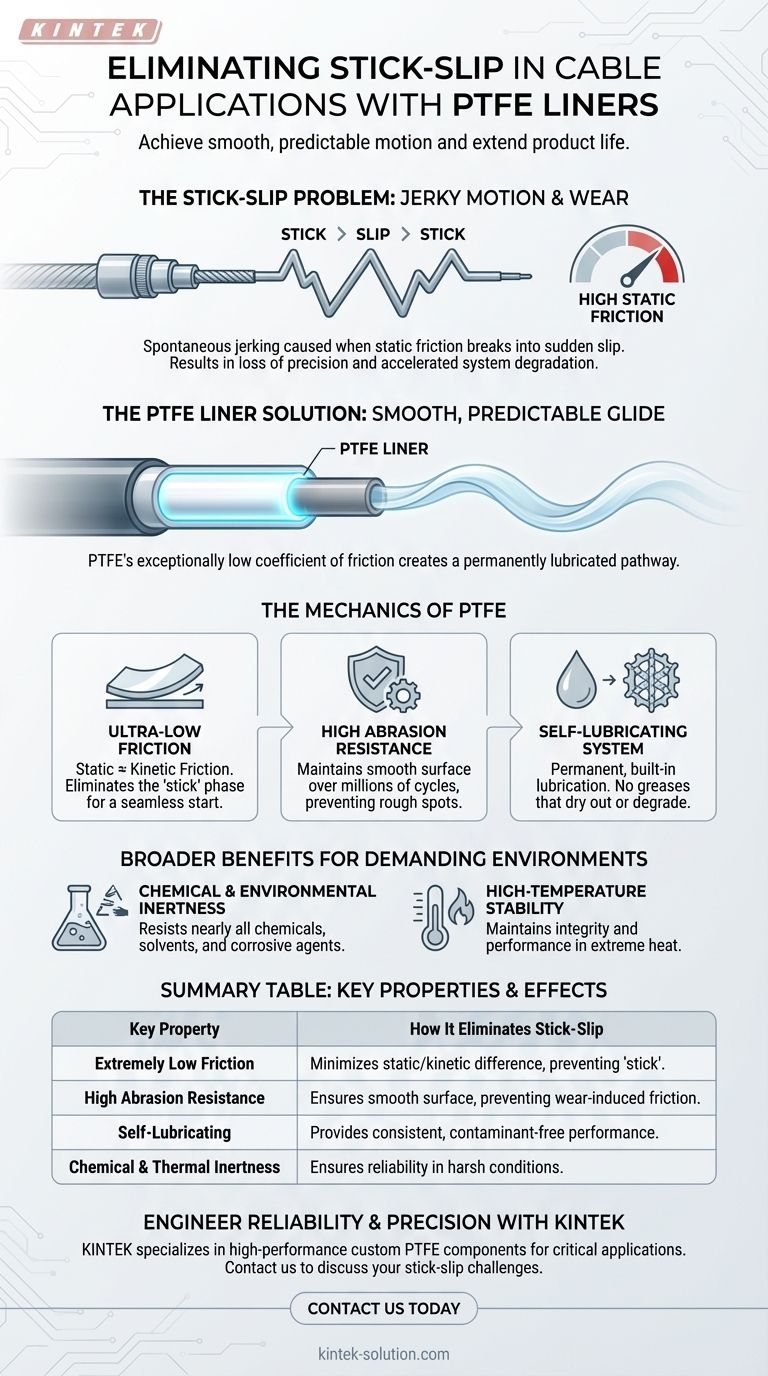

The Mechanics of Stick-Slip in Cables

What is Stick-Slip?

Stick-slip is the spontaneous jerking motion that occurs when one object slides over another. It's a rapid cycle of the surfaces sticking (due to static friction) and then slipping once the applied force overcomes that friction.

This phenomenon occurs when the static friction between two surfaces is significantly higher than the kinetic (sliding) friction. Force builds up until it breaks the static bond, causing a sudden slip, after which the surfaces immediately try to stick again.

Why It Matters in Cable Systems

In any mechanical cable system, from industrial robotics to medical endoscopes, stick-slip is a critical failure point.

This jerky, uncontrolled movement translates directly into a loss of precision. It also dramatically accelerates wear and tear on both the inner cable and the outer conduit, leading to system degradation and eventual failure.

How PTFE Provides the Definitive Solution

Exceptionally Low Coefficient of Friction

PTFE possesses one of the lowest coefficients of friction of any known solid material. This is its primary weapon against stick-slip.

Because the difference between PTFE's static and kinetic friction is almost zero, the force required to start the cable moving is virtually the same as the force needed to keep it moving. This eliminates the "stick" phase entirely, resulting in a perfectly smooth slide.

High Abrasion Resistance

A low-friction surface is only useful if it lasts. PTFE is highly resistant to abrasion from the cable moving back and forth within it.

This inherent durability means the liner maintains its anti-friction properties over millions of cycles, preventing the formation of rough spots that could reintroduce friction and wear.

Creating a Self-Lubricating System

A PTFE liner essentially provides permanent, built-in lubrication.

Unlike applied greases or oils, which can dry out, attract contaminants, or degrade under chemical or thermal stress, PTFE's properties are an integral part of the material. This ensures consistent performance for the life of the component.

Understanding the Broader Benefits

Chemical and Environmental Inertness

PTFE is famously inert and resistant to nearly all chemicals, solvents, and corrosive agents.

This makes it an ideal choice for cables operating in aggressive industrial environments or sterile medical applications where contamination or material degradation is not an option.

High-Temperature Stability

The material's ability to withstand a wide range of temperatures adds to its versatility.

PTFE liners maintain their structural integrity and low-friction properties in applications exposed to significant heat, from automotive engine compartments to aerospace systems.

How to Apply This to Your Project

Before implementation, consider the complete system requirements. A PTFE liner is a premium component, and its value is maximized when engineered as a solution to a specific operational challenge.

- If your primary focus is precision and control: A PTFE liner is non-negotiable, as it provides the smooth, repeatable actuation required for robotics, medical devices, and sensitive instrumentation.

- If your primary focus is reliability and lifespan: The liner's combination of abrasion resistance and chemical inertness dramatically reduces wear, making it essential for mission-critical or low-maintenance systems.

- If your primary focus is performance in harsh environments: PTFE's resistance to heat and chemicals ensures the cable system will not fail due to environmental degradation.

Ultimately, integrating a PTFE liner is a strategic decision to engineer reliability and precision directly into your mechanical system.

Summary Table:

| Key Property | How It Eliminates Stick-Slip |

|---|---|

| Extremely Low Friction | Minimizes difference between static and kinetic friction, preventing the 'stick' phase. |

| High Abrasion Resistance | Maintains a smooth surface over millions of cycles, preventing wear-induced friction. |

| Self-Lubricating | Provides permanent, contaminant-free lubrication for consistent performance. |

| Chemical & Thermal Inertness | Ensures reliability in harsh environments where other materials fail. |

Eliminate stick-slip and enhance your cable system's precision and durability.

At KINTEK, we specialize in manufacturing high-performance, custom PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our precision production ensures your components deliver the smooth, reliable motion critical for your application, from prototypes to high-volume orders.

Contact us today to discuss how a custom PTFE liner can solve your stick-slip challenges and extend your product's lifecycle.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What is another name for PTFE V Ring? It's Also Known as a Teflon V Ring

- What are the alternatives to PTFE sheet lining for chemical tanks? Explore Better Options

- What are the advantages of using PTFE gaskets? Achieve Superior Chemical and Thermal Sealing

- What is PTFE used for in bearing bushings? To enable self-lubrication in extreme environments.

- What industrial applications commonly use PTFE gaskets? Solve Your Toughest Sealing Challenges

- What are PTFE O-rings? High-Performance Seals for Extreme Conditions

- What additional safety feature do PTFE compensators provide? Prevent Electrical Sparks in Hazardous Environments

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability