The primary reason PTFE extruded rods are used in chemical processing is their almost universal chemical resistance. This material's unique molecular structure makes it non-reactive to nearly all acids, bases, and solvents, ensuring equipment longevity and preventing contamination in highly corrosive environments.

The core takeaway is that Polytetrafluoroethylene (PTFE) is not just resistant to some chemicals; it is fundamentally inert. This makes it the default material choice for components that must maintain structural integrity and purity when in direct contact with the most aggressive substances.

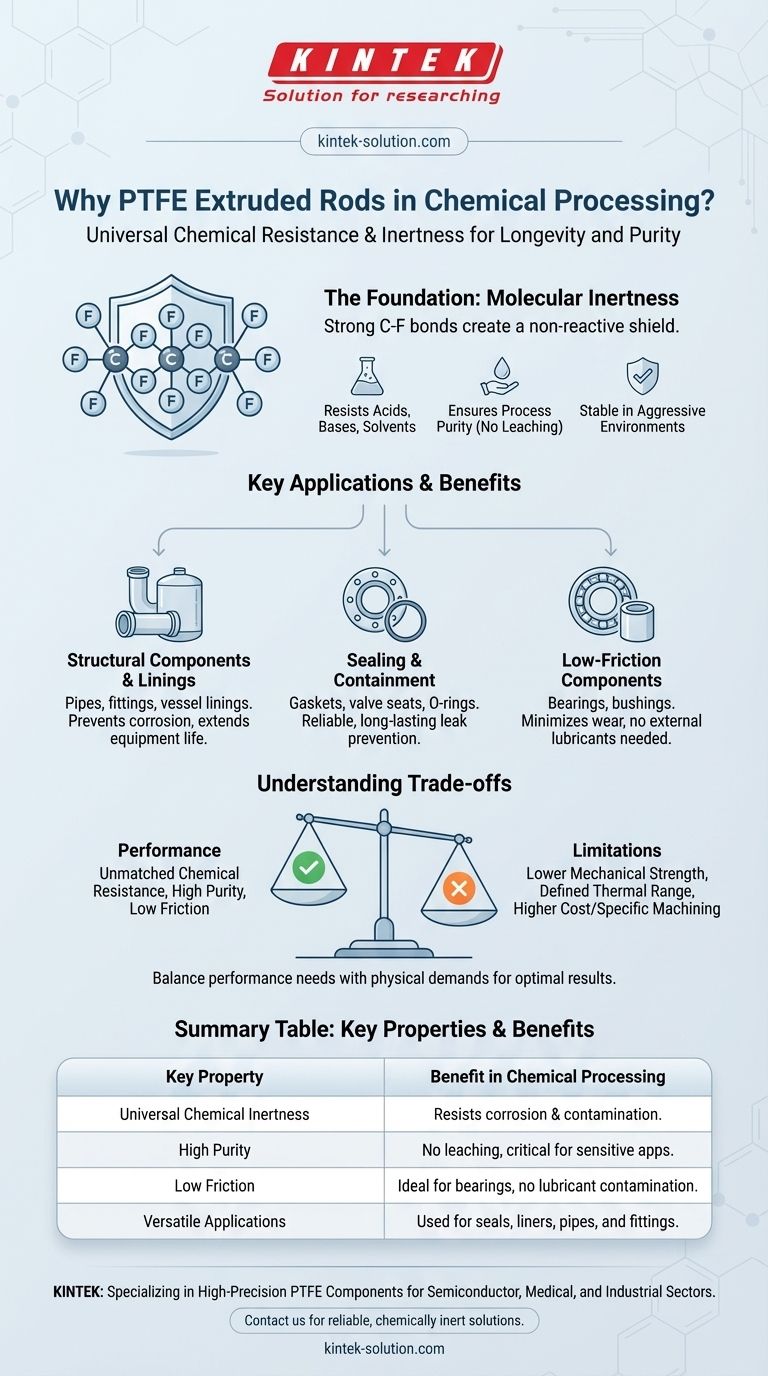

The Foundation of PTFE's Performance: Chemical Inertness

The value of PTFE in chemical processing originates at the molecular level. Its properties are not additives but are inherent to the material itself.

The Molecular Structure Advantage

PTFE's molecular structure consists of a carbon backbone fully encased by fluorine atoms. The carbon-fluorine bond is exceptionally strong and stable, creating a non-reactive surface that effectively shields the material from chemical attack.

A Broad Spectrum of Resistance

This inert nature allows PTFE rods to withstand prolonged exposure to a vast range of aggressive chemicals. This includes highly corrosive acids, potent bases, and industrial solvents that would quickly degrade most other polymers and even many metals.

Ensuring Process Purity

Because PTFE is so non-reactive, it does not leach chemicals or contaminate the substances it touches. This is critical in applications where the purity of the final product, such as in pharmaceuticals or specialty chemicals, is paramount.

Key Applications in Chemical Processing

The properties of PTFE make it uniquely suited for several critical roles within a chemical processing plant, where reliability is non-negotiable.

Structural Components and Linings

Extruded rods are machined into essential components like pipes, fittings, and vessel linings. Using PTFE ensures these parts will not corrode or fail, even under constant exposure to harsh chemicals, extending the operational life of the equipment.

Sealing and Containment

In any fluid system, preventing leaks is crucial. PTFE's ability to resist chemical degradation makes it the ideal material for flange gaskets, valve seats, and O-rings in pumps and reactors, ensuring a reliable and long-lasting seal.

Low-Friction Components

For moving parts within chemical equipment, PTFE is an excellent choice for bearings and bushings. Its chemical resistance ensures reliable operation, while its naturally low coefficient of friction minimizes wear and energy consumption without requiring external lubricants that could contaminate the process.

Understanding the Trade-offs

While its chemical performance is unmatched, PTFE is not a universal solution. Understanding its limitations is key to proper application.

Mechanical Limitations

PTFE is a relatively soft material with lower tensile strength and abrasion resistance compared to metals or engineering plastics. It is not suitable for high-load structural applications unless reinforced or used as a liner for a stronger material like steel.

Thermal Considerations

PTFE has a well-defined and useful service temperature range, but it is not intended for high-heat applications where ceramics or specialty metals would be required. Its performance can degrade at extreme temperatures.

Cost and Machinability

As a high-performance polymer, PTFE is typically more expensive than common plastics. While it can be machined into complex shapes from extruded rods, it requires specific techniques to achieve tight tolerances without causing stress to the material.

Making the Right Choice for Your Application

Selecting the right material requires balancing performance needs with physical demands.

- If your primary focus is maximum chemical resistance and purity: PTFE is the unparalleled choice for any component in direct contact with corrosive media.

- If your application involves high mechanical stress and chemical exposure: Consider using PTFE as a liner inside a structurally robust metal housing.

- If you need to create a leak-proof seal in a corrosive environment: PTFE gaskets, O-rings, and valve seats offer the most reliable long-term performance.

Ultimately, specifying PTFE extruded rods for chemical processing components is a strategic decision for ensuring operational reliability and safety in the most demanding environments.

Summary Table:

| Key Property | Benefit in Chemical Processing |

|---|---|

| Universal Chemical Inertness | Resists virtually all acids, bases, and solvents, preventing corrosion and contamination. |

| High Purity | Non-reactive surface ensures no leaching, critical for pharmaceuticals and specialty chemicals. |

| Low Friction | Ideal for bearings and bushings without needing lubricants that could contaminate the process. |

| Versatile Applications | Used for seals, liners, pipes, and fittings in highly corrosive environments. |

Need reliable, chemically inert components for your processing equipment?

At KINTEK, we specialize in manufacturing high-precision PTFE components—including extruded rods, seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication ensures you get parts that meet exact specifications, from prototypes to high-volume orders, guaranteeing longevity and purity in your most demanding applications.

Contact us today to discuss how our PTFE solutions can enhance your chemical processing equipment's performance and reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials