To put it simply, Teflon (PTFE) plastic sheets are exceptionally versatile because they possess a rare combination of high-performance properties that other materials cannot match. Their ability to simultaneously resist aggressive chemicals, withstand extreme temperatures, and provide an incredibly low-friction surface makes them an indispensable problem-solver across dozens of industries, from aerospace to food processing.

The true value of Teflon is not in any single attribute, but in its unique ability to solve critical engineering challenges in harsh environments where conventional plastics or metals would quickly fail. It thrives under conditions of extreme chemical, thermal, and mechanical stress.

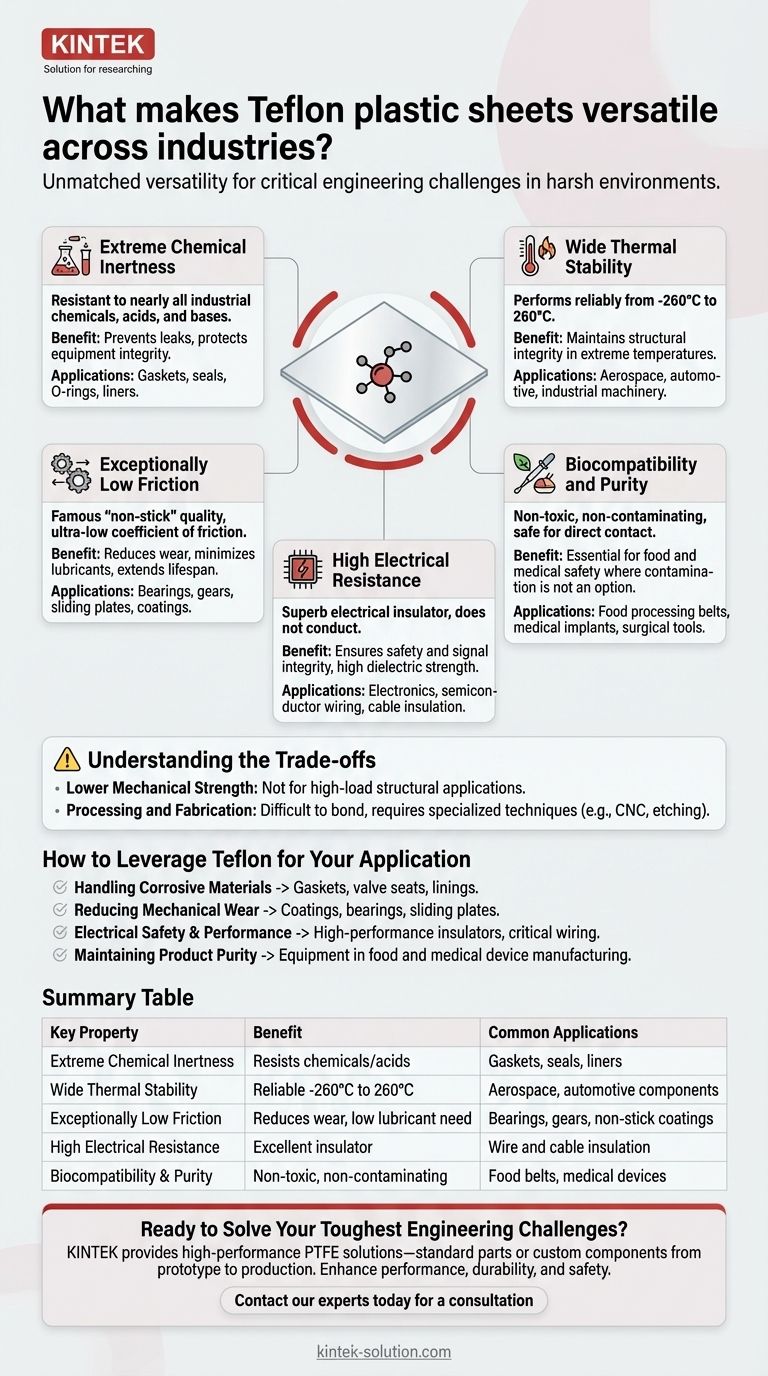

The Core Properties Driving Teflon's Adaptability

Teflon's versatility isn't accidental; it stems from the fundamental molecular structure of Polytetrafluoroethylene (PTFE). This structure gives rise to a set of distinct properties that make it uniquely suited for demanding applications.

Extreme Chemical Inertness

Teflon is resistant to nearly all industrial chemicals, acids, and bases. This makes it an ideal material for handling corrosive substances.

This property is critical in chemical processing plants, laboratories, and manufacturing facilities where equipment is constantly exposed to harsh materials. It is frequently used for gaskets, seals, O-rings, and liners to prevent leaks and protect equipment integrity.

Wide Thermal Stability

Teflon performs reliably across an exceptionally broad temperature range, typically from -260°C to 260°C (-436°F to 500°F).

It maintains its structural integrity and properties in cryogenic applications as well as in high-heat industrial processes, a feat few other polymers can achieve. This makes it invaluable in aerospace, automotive, and industrial machinery.

Exceptionally Low Friction

Teflon has one of the lowest coefficients of friction of any known solid material, giving it its famous "non-stick" quality.

This characteristic is essential for reducing wear and tear on moving parts like bearings and gears. It minimizes the need for liquid lubricants, reduces operational downtime, and extends the lifespan of machinery, especially in high-speed applications.

High Electrical Resistance

As a superb electrical insulator, Teflon does not conduct electricity. It maintains its high dielectric strength even at high frequencies and temperatures.

This makes it a critical component in the electronics and semiconductor industries for insulating wires, cables, and other sensitive electrical components, ensuring safety and signal integrity.

Biocompatibility and Purity

Teflon is non-toxic and does not contaminate the materials it touches, making it safe for direct contact with food and for use in medical devices.

This purity is essential in food processing for belts and liners and in the medical field for implants and surgical tools where contamination is not an option.

Understanding the Trade-offs

No material is perfect for every situation. Being a trusted advisor means acknowledging a material's limitations to ensure it is used correctly.

Lower Mechanical Strength

While durable, Teflon is a relatively soft material. It is not intended for high-load structural applications where materials like steel or aluminum are required for their rigidity and strength.

Its value lies in its surface properties and resilience, not its ability to bear heavy mechanical loads.

Processing and Fabrication

The same chemical inertness that makes Teflon so useful also makes it difficult to bond using conventional adhesives.

Specialized techniques like CNC machining or surface etching are often required to shape the material or prepare it for bonding, which can add complexity to the manufacturing process.

How to Leverage Teflon for Your Application

Choosing the right material depends entirely on the problem you need to solve. Teflon offers a clear solution for specific, high-stakes challenges.

- If your primary focus is handling corrosive materials: Teflon's chemical inertness makes it the definitive choice for gaskets, valve seats, and container linings.

- If your primary focus is reducing mechanical wear: Its ultra-low friction surface is ideal for coatings, bearings, and sliding plates in machinery.

- If your primary focus is electrical safety and performance: Use it as a high-performance insulator for critical wiring and electronic components, especially in high-temperature environments.

- If your primary focus is maintaining product purity: Its biocompatibility and non-reactive surface are essential for equipment in food production and medical device manufacturing.

Ultimately, leveraging Teflon effectively means applying its unique combination of properties to solve the most demanding engineering challenges.

Summary Table:

| Key Property | Benefit | Common Applications |

|---|---|---|

| Extreme Chemical Inertness | Resists nearly all industrial chemicals, acids, and bases. | Gaskets, seals, liners in chemical processing. |

| Wide Thermal Stability | Performs reliably from -260°C to 260°C. | Components in aerospace, automotive, and industrial machinery. |

| Exceptionally Low Friction | Reduces wear and tear, minimizes need for lubricants. | Bearings, gears, sliding plates, non-stick coatings. |

| High Electrical Resistance | Excellent insulator, even at high temperatures. | Wire and cable insulation in electronics and semiconductors. |

| Biocompatibility & Purity | Non-toxic and non-contaminating. | Food processing belts, medical devices, and surgical tools. |

Ready to Solve Your Toughest Engineering Challenges?

Teflon's unique properties make it the ideal choice for demanding applications in the semiconductor, medical, laboratory, and industrial sectors. At KINTEK, we don't just supply PTFE components—we provide high-performance solutions.

We specialize in the precision manufacturing of PTFE sheets, seals, liners, and custom labware. Whether you need a standard part or a custom-fabricated component from prototype to high-volume production, our expertise ensures a perfect fit for your application's critical requirements.

Let's discuss how our PTFE components can enhance your product's performance, durability, and safety.

Contact our experts today for a consultation

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the primary applications of extra-thick PTFE washers (5mm – 6mm)? Critical for High-Pressure Sealing & Load-Bearing

- What advantages does PTFE offer as an engineering plastic in CNC machining? Unlock Superior Performance for Extreme Environments

- What are the advantages of using PTFE ring gaskets? Superior Sealing for Demanding Applications

- How do PTFE bellow seals perform with chemical reagents? Superior Resistance to Corrosive Chemicals

- Why are Teflon bushes suitable for food and pharmaceutical manufacturing? Ensuring Purity and Safety

- How often should a PTFE coating thrust washer be replaced? Proactive Maintenance for Peak Performance

- What are PTFE heat press sheets commonly known as? Achieve Flawless Heat Transfer with Teflon Sheets

- What additional properties do PTFE O-rings require besides thermal resistance? Master Chemical and Mechanical Sealing