In essence, Teflon bushes are suitable for food and pharmaceutical manufacturing because they are chemically inert and self-lubricating. This unique combination ensures they do not react with or leach into sensitive products, while also eliminating the need for external oils or greases, which are major sources of contamination.

The fundamental advantage of Teflon is its ability to mitigate risk. By being both non-reactive and eliminating the need for traditional lubricants, it directly addresses the two primary pathways for mechanical contamination in sterile production environments.

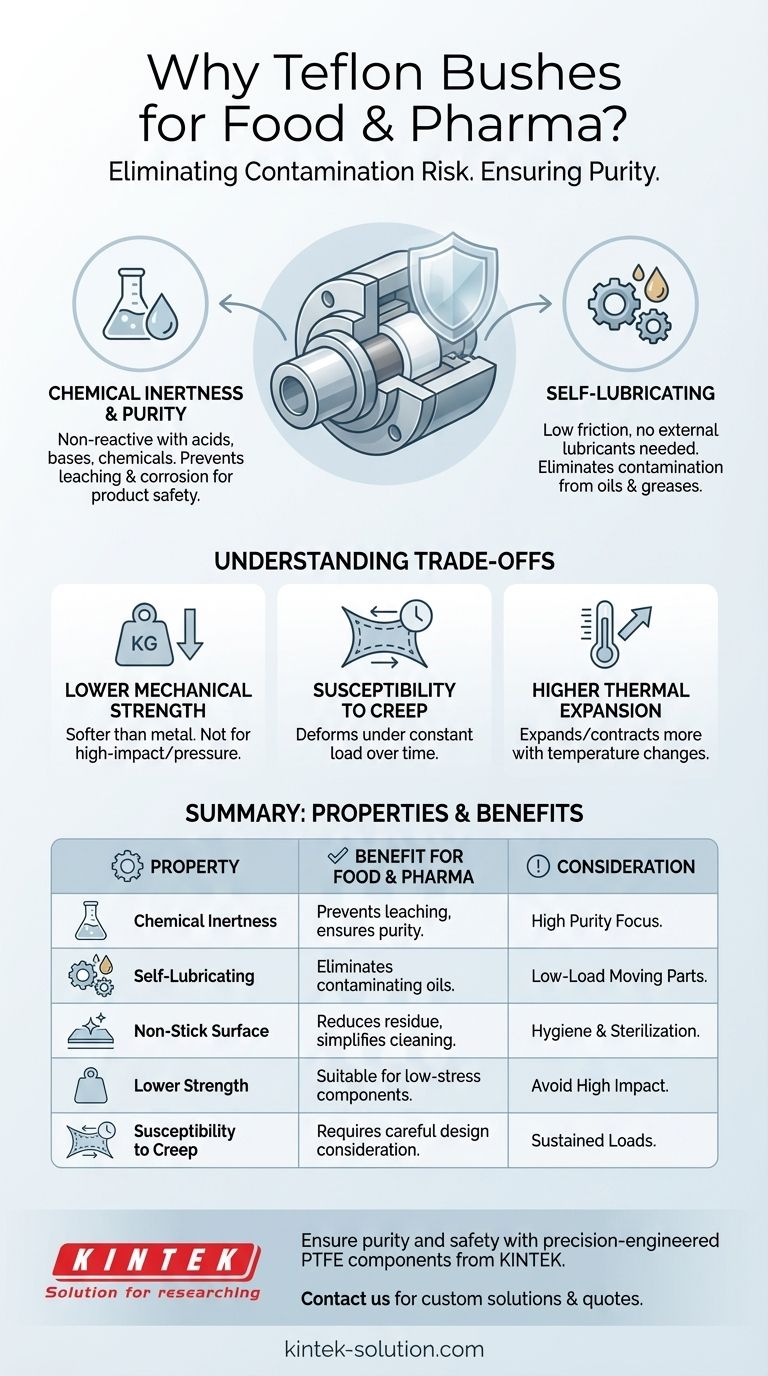

The Core Principle: Eliminating Contamination Risk

In food and pharmaceutical applications, the primary goal is to ensure product purity and safety. Every material that comes into contact with the product must be chosen to prevent contamination, not just withstand the process.

Chemical Inertness and Purity

Teflon (PTFE) is one of the most non-reactive materials known. It does not react with acids, bases, or other chemicals commonly found in food and drug production.

This chemical stability means the bushing will not corrode, degrade, or leach harmful substances into the product stream, ensuring the final product remains uncontaminated and safe for consumption.

Self-Lubricating Properties

Perhaps the most critical feature is Teflon's extremely low coefficient of friction. It is inherently "slippery," allowing it to function as a bearing or guide without any external lubrication.

This eliminates the need for industrial oils and greases, which are significant contaminants. In machinery with moving parts like mixers or dispensers, using Teflon bushes prevents these lubricants from accidentally mixing with the product.

Non-Stick Surface

Teflon's famous non-stick surface also prevents product residue from building up on the machinery parts.

This quality makes equipment easier to clean and sterilize, reducing the risk of microbial growth between production batches and ensuring a consistently hygienic environment.

Understanding the Trade-offs

While Teflon's properties are ideal for purity, it is not a universal solution for all mechanical applications. Understanding its limitations is key to using it effectively.

Lower Mechanical Strength

Compared to bronze or steel bushings, Teflon is a much softer material. It has a lower load-bearing capacity and is not suitable for high-impact or extremely high-pressure applications.

Susceptibility to Creep

Under a constant, sustained load, Teflon can slowly deform over time, a phenomenon known as "creep." This must be accounted for in the design of machinery where precise, long-term tolerances are critical.

Higher Thermal Expansion

Teflon expands and contracts with temperature changes more significantly than metals. In applications with wide temperature swings, this must be engineered into the design to prevent parts from seizing or becoming too loose.

Making the Right Choice for Your Application

Selecting the right material requires balancing the absolute need for purity with the mechanical demands of the specific application.

- If your primary focus is product purity in low-load moving parts: Teflon is the ideal choice for components like shaft guides, mixers, and dispensers where contamination from lubricants is unacceptable.

- If your primary focus is high mechanical stress and load: A food-grade metallic bushing or a filled/reinforced PTFE composite may be a more appropriate choice to provide necessary strength.

- If your primary focus is precision in a variable-temperature environment: The design must explicitly account for Teflon's thermal expansion to ensure consistent and reliable operation.

Ultimately, understanding these material properties empowers you to build safer, more compliant, and more reliable manufacturing systems.

Summary Table:

| Property | Benefit for Food & Pharma Manufacturing |

|---|---|

| Chemical Inertness | Non-reactive; prevents leaching and corrosion, ensuring product purity. |

| Self-Lubricating | Eliminates need for contaminating oils and greases in moving parts. |

| Non-Stick Surface | Reduces residue buildup, simplifies cleaning and sterilization. |

| Lower Mechanical Strength | Not ideal for high-load applications; best for low-stress components. |

| Susceptibility to Creep | Can deform under constant load; requires careful design consideration. |

Ensure the purity and safety of your manufacturing process with precision-engineered PTFE components from KINTEK.

Whether you're in the semiconductor, medical, laboratory, or industrial sector, our custom-fabricated Teflon seals, liners, and labware are designed to meet the highest standards of chemical resistance and cleanliness. From initial prototypes to high-volume production, we prioritize precision to mitigate contamination risks in your critical applications.

Contact KINTEK today to discuss your specific needs and receive a quote for custom PTFE solutions.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Crucibles for Laboratory and Industrial Applications

People Also Ask

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications