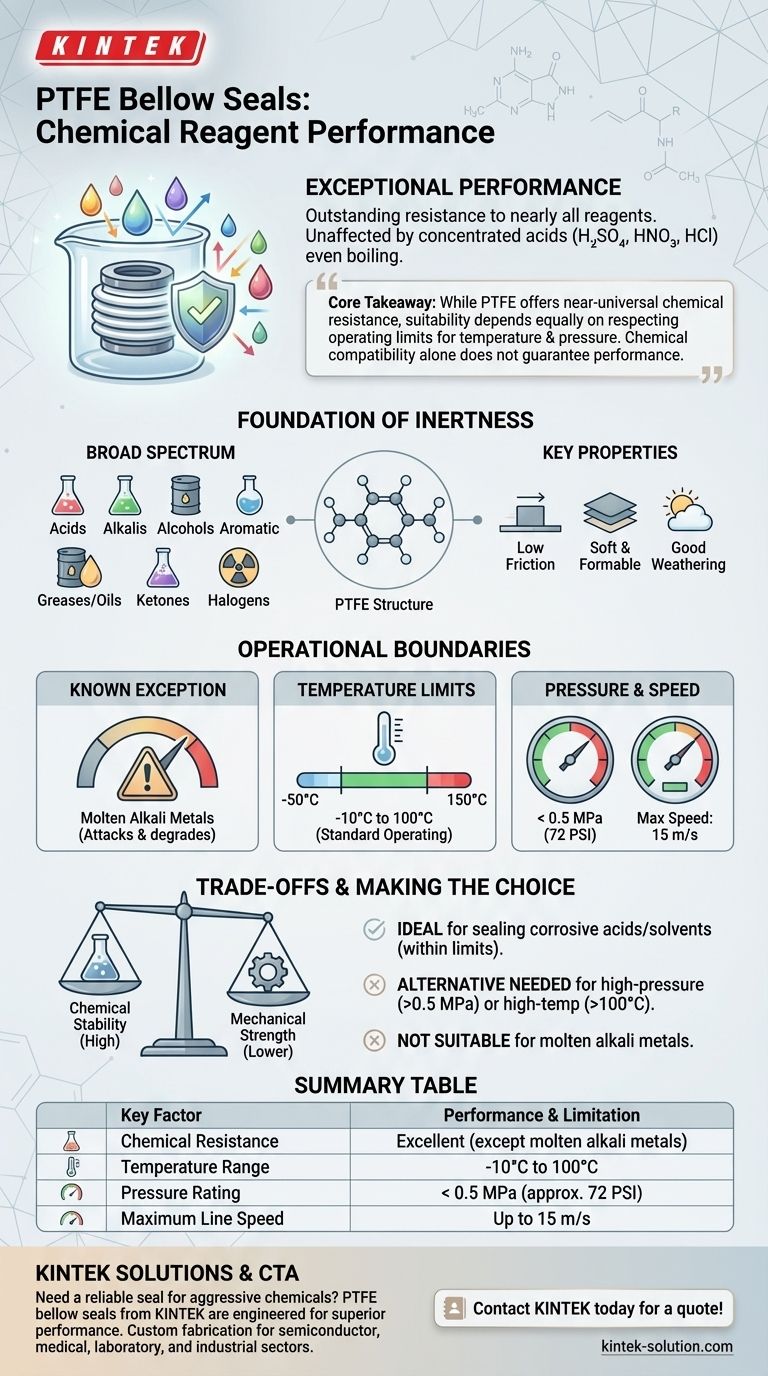

In short, the performance is exceptional. PTFE (Polytetrafluoroethylene) bellow seals exhibit outstanding resistance to nearly all chemical reagents. They remain completely unaffected by aggressive substances like concentrated sulfuric, nitric, or hydrochloric acid, even under boiling conditions. Their inertness makes them a default choice for many demanding chemical applications.

The core takeaway is that while PTFE bellow seals offer near-universal chemical resistance, their suitability for an application depends equally on respecting their specific operating limits for temperature and pressure. Chemical compatibility alone does not guarantee performance.

The Foundation of PTFE's Chemical Inertness

The remarkable performance of PTFE in chemical environments stems from its unique molecular structure and properties. This inherent stability is what makes it so valuable in sealing applications involving corrosive or reactive fluids.

A Broad Spectrum of Resistance

PTFE is not just resistant to a few strong acids; its inertness extends across a vast range of chemical families. It demonstrates excellent resistance to both concentrated and dilute acids, alkalis, and alcohols.

Furthermore, it reliably handles aromatic hydrocarbons, greases and oils, ketones, and even aggressive substances like halogens and halogenated hydrocarbons.

Key Material Properties

Beyond its chemical resilience, PTFE has other properties that contribute to its sealing capability. It has an extremely low coefficient of friction, is inherently soft and formable, and exhibits good weathering resistance, ensuring durability over time.

Understanding the Operational Boundaries

While chemically robust, PTFE bellow seals are not invincible. Their performance is defined by a specific set of operational parameters that must be respected to prevent mechanical failure. The seal's chemical resistance is irrelevant if its physical limits are exceeded.

The Known Chemical Exception

The primary chemical vulnerability of PTFE is contact with molten alkali metals. These are the only common reagents known to readily attack and degrade the material.

Strict Temperature Limitations

The standard operating temperature for these seals is between -10°C and 100°C. Operating outside this window can compromise the seal's integrity, even if the chemical compatibility is perfect.

Pressure and Speed Constraints

PTFE bellow seals are typically designed for lower-pressure systems. They are rated for an operating pressure of less than 0.5 MPa (approximately 72 PSI). Additionally, they have a maximum recommended line speed of 15 m/s.

The Trade-offs of Using PTFE Seals

Selecting a PTFE bellow seal involves balancing its unparalleled chemical stability against its distinct mechanical characteristics. Understanding these trade-offs is critical for successful implementation.

Chemical Stability vs. Mechanical Strength

The softness and formability that help PTFE create a tight seal also mean it has lower mechanical strength compared to metal or hard plastic seals. This makes it less suitable for high-pressure applications where extrusion or deformation could occur.

The Importance of the Complete Picture

A common pitfall is focusing solely on chemical resistance. A seal can fail from over-pressurization or excessive temperature just as easily as it can from chemical attack. You must evaluate all operating parameters—pressure, temperature, and media—to ensure reliability.

Making the Right Choice for Your Application

Use these guidelines to determine if a PTFE bellow seal is the correct solution for your specific operational goal.

- If your primary focus is sealing highly corrosive acids, alkalis, or organic solvents: PTFE is an ideal choice, as long as you operate within its specified temperature and pressure limits.

- If your primary focus is a high-pressure or high-temperature application (above 0.5 MPa or 100°C): You must seek an alternative seal material, as a standard PTFE bellow seal will likely fail mechanically.

- If your primary focus is handling molten alkali metals: PTFE is explicitly unsuitable and a different, specialized material must be selected.

By balancing PTFE's unmatched chemical resistance with its clear operational boundaries, you can confidently select the right seal for your critical application.

Summary Table:

| Key Factor | Performance & Limitation |

|---|---|

| Chemical Resistance | Excellent resistance to nearly all acids, alkalis, solvents, and hydrocarbons. Exception: Molten alkali metals. |

| Temperature Range | Standard operating range: -10°C to 100°C. |

| Pressure Rating | Operating pressure less than 0.5 MPa (approx. 72 PSI). |

| Maximum Line Speed | Up to 15 m/s. |

Need a reliable seal for aggressive chemicals?

PTFE bellow seals from KINTEK are engineered for superior performance in the most demanding environments. Whether you're in the semiconductor, medical, laboratory, or industrial sector, our precision-manufactured PTFE components—including seals, liners, and labware—are designed to handle your toughest challenges.

We offer custom fabrication from prototypes to high-volume orders, ensuring a perfect fit for your specific application requirements.

Contact KINTEK today to discuss your sealing needs and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What advantages do PTFE bearings offer in aviation systems? Achieve Lighter, More Reliable Aircraft Performance

- How are PTFE bushes manufactured to ensure quality? A Guide to Precision and Reliability

- How should the static ring and gland of a PTFE gasket be installed? A Step-by-Step Guide to a Leak-Free Seal

- How has sourcing Teflon parts from global suppliers improved supply chain efficiency?

- What are the applications of silicate/quartz fillers in PTFE? Enhance Sealing for Steel Pipelines

- What are the structural differences between PTFE oil seals and rubber oil seals? A Guide to Lip Design & Performance

- What are the properties of stainless steel-filled PTFE balls? A Guide to Enhanced Strength & Performance

- What are some common applications for hard PTFE grades? Solve High-Load, High-Wear Engineering Challenges