At their core, extra-thick PTFE washers (5mm – 6mm) are specified for applications demanding significant structural support, high-pressure sealing, or robust electrical insulation. Their primary uses include serving as load-bearing components in heavy machinery, sealing critical joints in oil and gas pipelines, and providing structural insulation in high-power industrial equipment.

The critical distinction for an extra-thick PTFE washer is its function: it transitions from a simple surface-protecting spacer to a robust structural component. Its thickness provides the necessary bulk to withstand high compressive loads, seal against extreme pressures, and maintain integrity as a durable insulator.

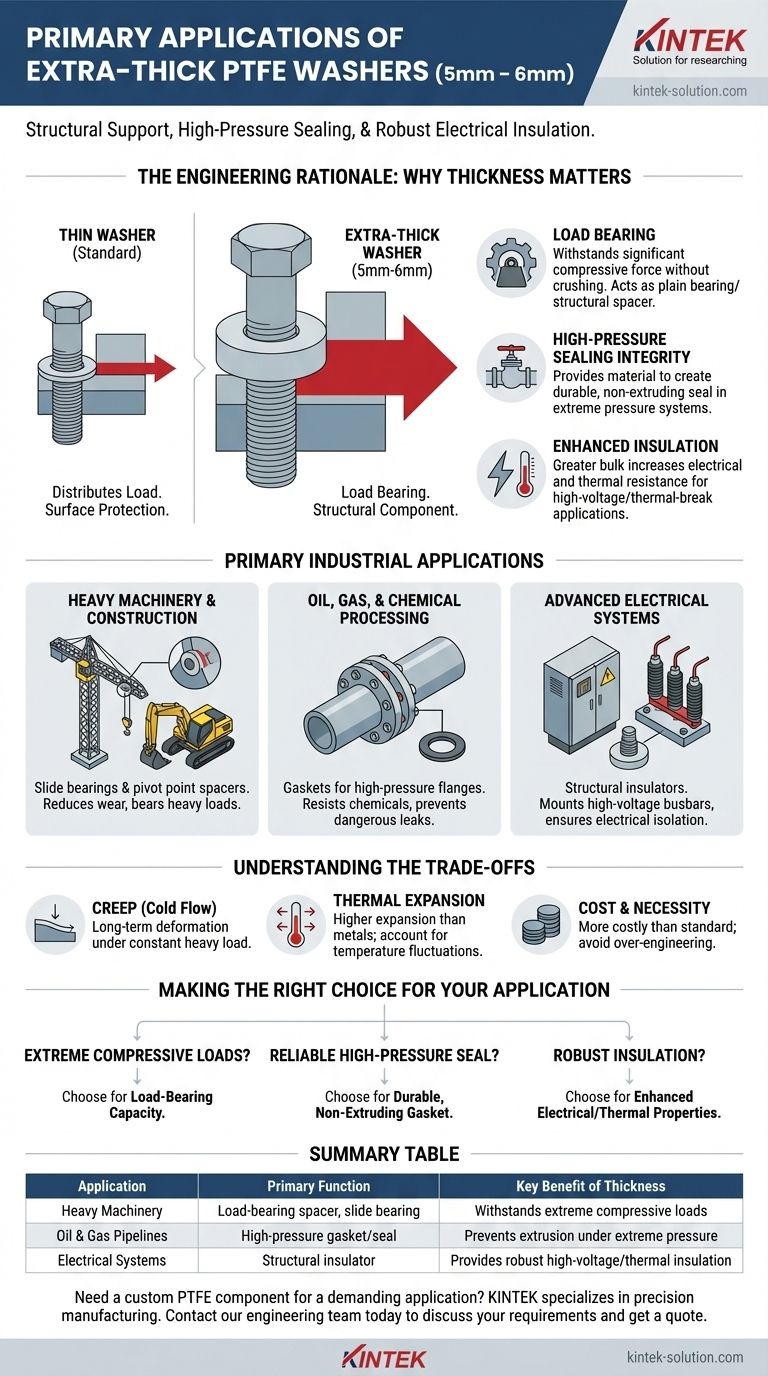

The Engineering Rationale: Why Thickness Matters

The decision to use a 5mm or 6mm PTFE washer is driven by engineering demands that a standard, thinner washer cannot meet. The added thickness fundamentally changes the component's mechanical and insulative properties.

From Load Distribution to Load Bearing

A thin washer primarily distributes the load from a screw or bolt head across a wider surface area to prevent damage.

An extra-thick washer, however, acts as a load-bearing element. It can withstand significant compressive force without being crushed, making it suitable as a plain bearing or a structural spacer between major components.

High-Pressure Sealing Integrity

In high-pressure systems, like oil and gas pipelines, a seal must be able to deform slightly to fill imperfections in flange surfaces without being destroyed.

The substantial thickness provides the necessary material to create a durable, resilient seal that resists being extruded out of the joint under extreme pressure.

Enhanced Electrical and Thermal Insulation

Insulation capability is directly related to the thickness of the insulating material.

For high-voltage electrical applications or where a thermal break is required, the added bulk of a 5mm-6mm washer provides significantly greater electrical and thermal resistance than a standard washer.

Primary Industrial Applications in Detail

The unique properties of thick PTFE washers make them essential in several demanding fields.

Heavy Machinery and Construction

In equipment like cranes, excavators, and industrial presses, these washers are used as slide bearings and pivot point spacers. Their low friction reduces wear on moving metal parts, while their durability allows them to bear heavy, continuous loads.

Oil, Gas, and Chemical Processing

Thick PTFE washers are frequently used as gaskets for flange connections in high-pressure pipelines.

PTFE's exceptional chemical resistance ensures it will not degrade when exposed to corrosive fluids, and its thickness provides the robust seal needed to prevent dangerous leaks.

Advanced Electrical Systems

In power distribution units or large industrial electronics, these washers serve as structural insulators. They can be used to mount high-voltage busbars or other large components, ensuring they remain electrically isolated from the chassis.

Understanding the Trade-offs

While powerful, extra-thick PTFE washers are not a universal solution. Their material properties introduce specific design considerations.

Potential for Creep (Cold Flow)

PTFE can slowly deform over time when subjected to a constant, heavy load—a phenomenon known as creep or cold flow. While thickness improves resistance, this must be calculated for in long-term, high-stress structural applications.

Higher Thermal Expansion

PTFE has a significantly higher coefficient of thermal expansion than metals. In assemblies that experience wide temperature fluctuations, the expansion and contraction of the washer must be accounted for to avoid stressing other components.

Cost and Necessity

These are specialized components that are more costly than standard thin washers. Using one where it is not required represents over-engineering and unnecessary expense.

Making the Right Choice for Your Application

Selecting the correct component requires matching its capabilities to your primary engineering goal.

- If your primary focus is managing extreme compressive loads: Choose an extra-thick washer for its load-bearing capacity, especially in heavy equipment pivot points or as a structural spacer.

- If your primary focus is creating a reliable high-pressure seal: The thickness provides the necessary material to form a durable, non-extruding gasket in chemical or gas pipelines.

- If your primary focus is robust electrical or thermal isolation: The added thickness directly enhances the washer's insulative properties for high-voltage or thermal-break applications.

Ultimately, choosing an extra-thick PTFE washer is a deliberate engineering decision for when standard components simply cannot provide the required structural or sealing integrity.

Summary Table:

| Application | Primary Function | Key Benefit of Thickness |

|---|---|---|

| Heavy Machinery | Load-bearing spacer, slide bearing | Withstands extreme compressive loads |

| Oil & Gas Pipelines | High-pressure gasket/seal | Prevents extrusion under extreme pressure |

| Electrical Systems | Structural insulator | Provides robust high-voltage/thermal insulation |

Need a custom PTFE component for a demanding application?

Your high-pressure sealing, structural support, or critical insulation challenge requires a component built for the task. KINTEK specializes in precision manufacturing of custom PTFE components—including extra-thick washers, seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors.

We deliver the durability and performance you need, from rapid prototypes to high-volume production runs.

Contact our engineering team today to discuss your specific requirements and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the key features of TFE Encapsulated O-Rings and Gaskets? Achieve Superior Sealing in Demanding Environments

- What is the importance of torque checks in PTFE butterfly valves? Prevent Leaks & Extend Valve Life

- Can Teflon PTFE sheets be customized in size? Achieve Precise Custom PTFE Components for Your Industry

- What are the advantages and disadvantages of filled PTFE diaphragms? Enhance Durability & Cost-Effectiveness

- What industries commonly use PTFE expansion joints and why? Solve Critical Pipeline Challenges with PTFE

- What environmental factors should be considered when choosing PTFE sheets? Ensure Long-Term Performance

- What are the advantages of using PTFE as the material for rotary shaft lip seals? Achieve Unmatched Reliability in Extreme Conditions

- What are the key features of PTFE Expansion Bellows? Ensure System Safety & Reliability