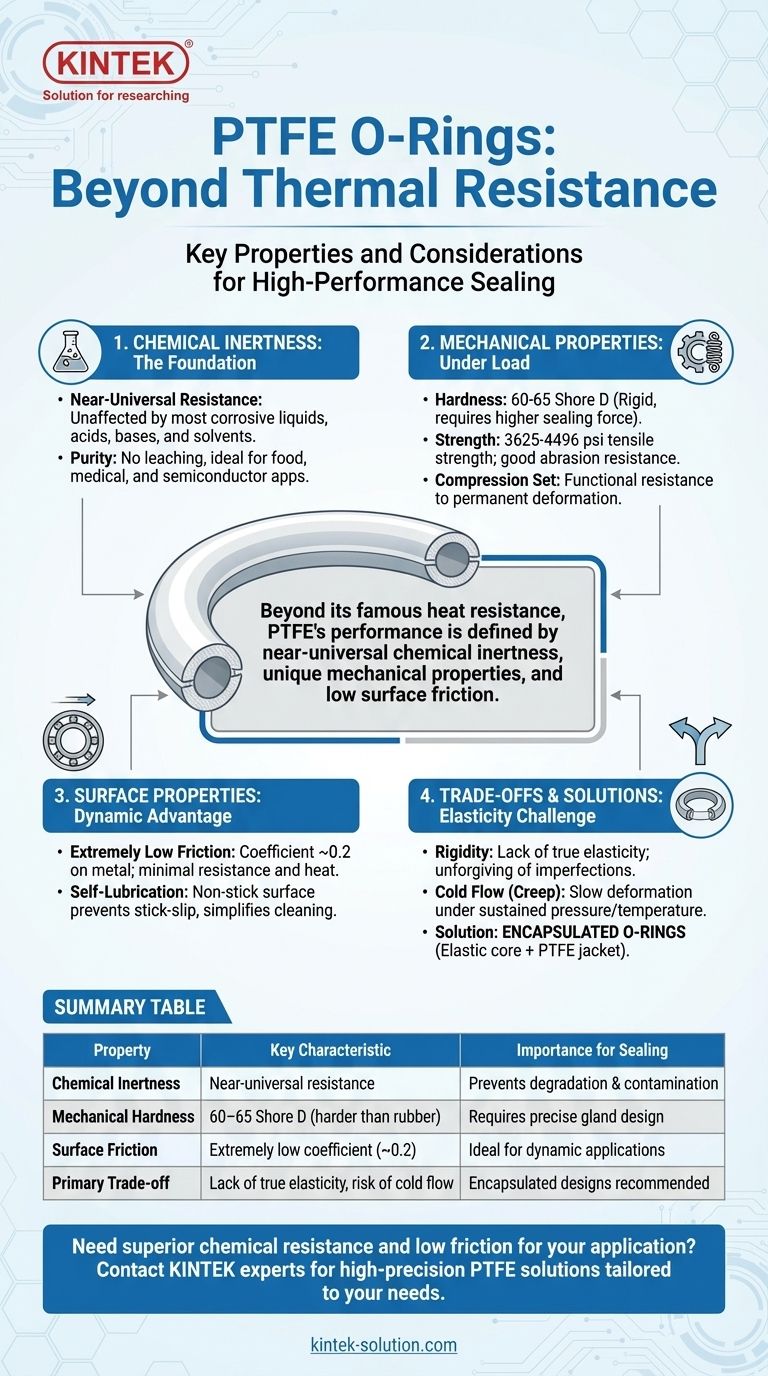

Beyond its famous heat resistance, a PTFE O-ring's performance is critically defined by its near-universal chemical inertness and unique mechanical properties. These characteristics make it a specialized sealing solution for environments where conventional elastomers would quickly fail. Its low-friction surface further expands its use into dynamic applications.

The core takeaway is that while PTFE's thermal stability is exceptional, its primary value in sealing comes from its ability to withstand virtually any chemical. However, this advantage is balanced by its relative rigidity compared to rubber, a critical trade-off that must be considered in any design.

The Foundation of a Reliable Seal: Chemical Inertness

The single most important property of PTFE, besides thermal stability, is its profound resistance to chemical attack.

### Near-Universal Resistance

PTFE is the most chemically resistant plastic known. It is virtually unaffected by corrosive liquids, gases, acids, bases, and solvents that would degrade other materials.

### Purity and Non-Contamination

Because it is so inert, PTFE does not leach contaminants into the fluids it contains. This, combined with its non-stick surface, makes it an excellent choice for sanitary applications in the food, medical, and semiconductor industries.

Performance Under Load: Key Mechanical Properties

How an O-ring behaves physically under pressure is just as important as its chemical resistance. PTFE has a distinct mechanical profile.

### Hardness and Sealing Force

PTFE O-rings typically have a durometer (hardness) of 60-65 on the Shore D scale. This is significantly harder than most rubber O-rings, meaning more force is required to create an effective seal.

### Strength and Durability

With a tensile strength between 3625 and 4496 psi, PTFE is a strong material. This contributes to its good resistance to abrasion and wear, especially in applications with moving parts.

### Resistance to Permanent Deformation

A material's ability to return to its original shape after being compressed is known as its compression set. While PTFE is not a true elastomer, it offers a functional resistance to taking a permanent set, which is crucial for maintaining a long-term seal.

The Advantage in Dynamic Applications: Surface Properties

For seals that involve movement, such as on a rotating shaft or a piston, the surface characteristics of the O-ring are paramount.

### Extremely Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, measured at around 0.2 on metal. This means parts can move against it with minimal resistance and heat generation.

### Self-Lubrication and Non-Stick Surface

This low friction also gives PTFE self-lubricating properties. It prevents the stick-slip phenomenon common in other seals and makes for much smoother, more reliable operation. Its non-stick nature also simplifies cleaning and maintenance.

Understanding the Trade-offs: The Challenge of Elasticity

No material is perfect, and PTFE's primary trade-off is its lack of true elasticity. This is a critical factor to understand for successful seal design.

### The Rigidity of Solid PTFE

Unlike rubber, PTFE is a relatively rigid plastic. It does not have the "bounciness" or memory of an elastomer. This means it is less forgiving of imperfections in sealing surfaces and requires careful design of the gland (the groove it sits in).

### The Risk of Cold Flow (Creep)

Under sustained pressure, especially at elevated temperatures, PTFE has a tendency to "cold flow" or creep. This means it can slowly deform over time, potentially leading to a loss of sealing force in long-term static applications.

### The Solution: Encapsulation

To overcome this limitation, encapsulated O-rings are often used. These feature an elastic core (like silicone or FKM rubber) covered by a thin, seamless jacket of PTFE. This design combines the elasticity and memory of rubber with the chemical and thermal resistance of PTFE.

Making the Right Choice for Your Goal

Selecting the correct sealing material depends entirely on the demands of your application.

- If your primary focus is extreme chemical resistance: PTFE is the industry standard and often the only viable choice for aggressive media.

- If your application involves dynamic movement: The low friction of PTFE is a significant advantage, but ensure your design accommodates its rigidity.

- If you need a reliable, long-term static seal at high pressure: You must carefully engineer the gland to account for PTFE's potential for cold flow, or consider an encapsulated O-ring.

Ultimately, understanding this complete profile of properties allows you to leverage PTFE's exceptional strengths while mitigating its inherent limitations.

Summary Table:

| Property | Key Characteristic | Importance for Sealing |

|---|---|---|

| Chemical Inertness | Near-universal resistance to acids, bases, solvents | Prevents degradation and contamination in harsh environments |

| Mechanical Hardness | 60-65 Shore D (harder than rubber) | Requires precise gland design for effective sealing force |

| Surface Friction | Extremely low coefficient (~0.2) | Ideal for dynamic applications with moving parts |

| Primary Trade-off | Lack of true elasticity, risk of cold flow | Limits use in imperfect surfaces; encapsulated designs recommended |

Need a PTFE O-ring that delivers superior chemical resistance and low friction for your demanding application?

At KINTEK, we specialize in manufacturing high-precision PTFE components, including O-rings, seals, and custom fabrications for the semiconductor, medical, laboratory, and industrial sectors. We understand the critical balance of properties required for a reliable seal.

Our expertise ensures you get a solution that leverages PTFE's strengths while mitigating its limitations through precise design and material selection.

Contact our experts today to discuss your specific requirements and get a custom solution tailored for peak performance.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments