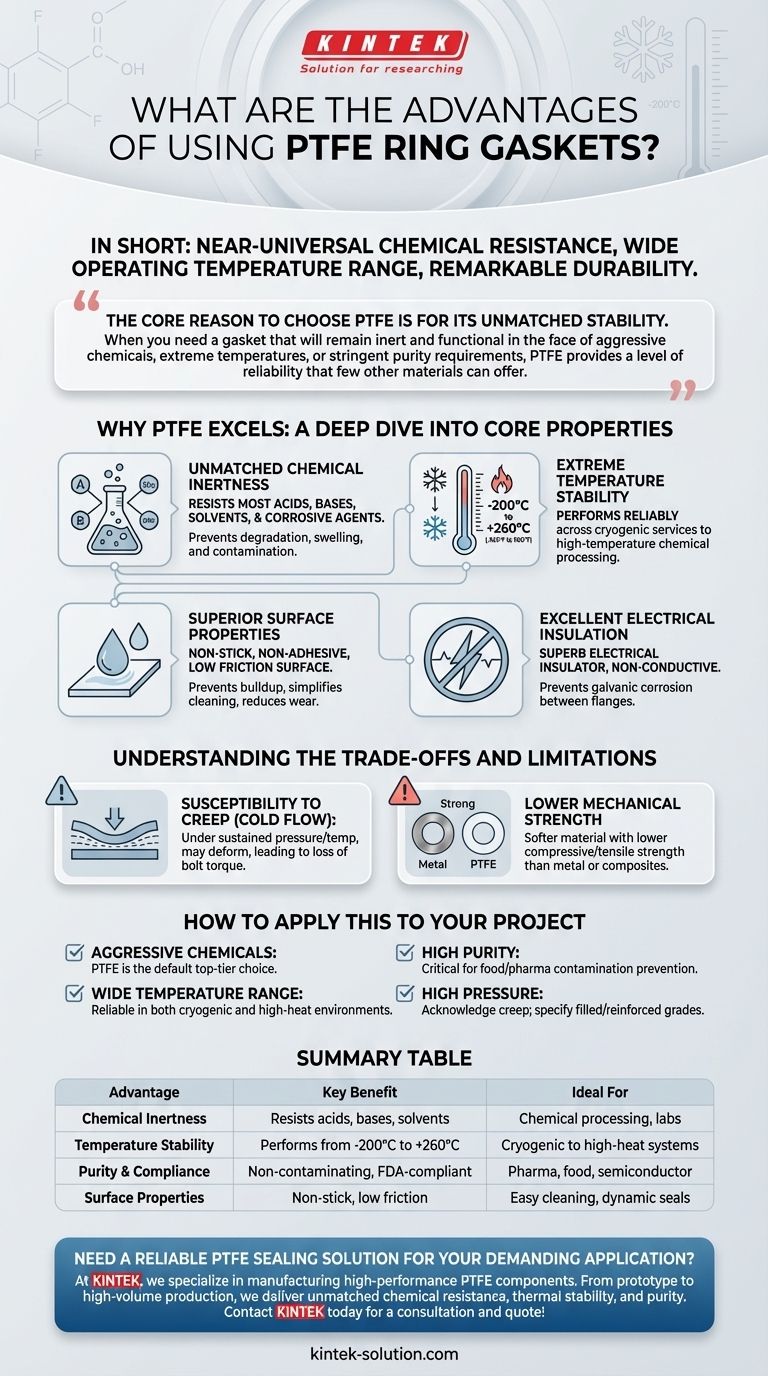

In short, the primary advantages of PTFE ring gaskets are their near-universal chemical resistance, an exceptionally wide operating temperature range, and remarkable durability. These properties make Polytetrafluoroethylene (PTFE) a premier sealing material for demanding industrial applications where lesser materials would quickly degrade and fail.

The core reason to choose PTFE is for its unmatched stability. When you need a gasket that will remain inert and functional in the face of aggressive chemicals, extreme temperatures, or stringent purity requirements, PTFE provides a level of reliability that few other materials can offer.

Why PTFE Excels: A Deep Dive into Core Properties

To understand if PTFE is the right choice, you must look beyond a simple list of benefits and understand how its fundamental properties translate into performance.

Unmatched Chemical Inertness

PTFE is famously resistant to a vast spectrum of chemicals, including most acids, bases, solvents, and corrosive agents.

This inertness means the gasket will not degrade or swell when exposed to aggressive media. This preserves the integrity of the seal and prevents contamination of the process fluid.

Extreme Temperature Stability

PTFE gaskets perform reliably across a massive temperature window, typically from -200°C to +260°C (-328°F to 500°F).

This makes it one of the few materials suitable for applications ranging from cryogenic services to high-temperature chemical processing, offering a versatile solution for plants with diverse operational requirements.

Superior Surface Properties

PTFE has an extremely low coefficient of friction, giving it a non-stick, non-adhesive surface.

This prevents process media from sticking to the gasket, simplifying cleaning and preventing material buildup. In dynamic or rotating applications, its low friction also reduces wear and tear on the components.

Purity and Compliance

Gaskets made from virgin PTFE are inherently pure and free from contaminants.

This non-contaminating characteristic makes them an ideal choice for sensitive industries like food and beverage, pharmaceuticals, and electronics, where preventing process contamination is non-negotiable. Many grades are available that are FDA-compliant.

Excellent Electrical Insulation

PTFE is a superb electrical insulator and is non-conductive.

This property is critical in applications where the gasket must prevent the flow of electrical current between two flange faces, helping to mitigate issues like galvanic corrosion.

Understanding the Trade-offs and Limitations

A trusted advisor must be clear about a material's limitations. While PTFE is exceptional, it is not universally perfect. Understanding its trade-offs is crucial for successful implementation.

Susceptibility to Creep (Cold Flow)

The most significant limitation of pure PTFE is its tendency to "creep" or "cold flow."

Under sustained pressure and temperature, the material can slowly deform, which can lead to a loss of bolt torque and a potential leak path over time. This is especially relevant in high-pressure applications or those with significant thermal cycling.

Lower Mechanical Strength

Compared to metallic gaskets or reinforced composite materials, PTFE is a relatively soft material with lower compressive and tensile strength.

This makes pure PTFE less suitable for extremely high-pressure systems where a more rigid material is required to resist crushing and extrusion. For these applications, filled or reinforced PTFE is often the necessary solution.

How to Apply This to Your Project

Your choice of gasket material should always be driven by the specific demands of your application.

- If your primary focus is aggressive chemical processing: PTFE's near-universal chemical resistance makes it the default, top-tier choice for ensuring seal longevity.

- If your application involves a wide temperature range: The exceptional thermal stability of PTFE provides a reliable seal in both cryogenic and high-heat environments.

- If you require high purity for food or pharmaceuticals: Virgin PTFE is a critical component for preventing process contamination and meeting regulatory standards.

- If you are designing for high-pressure service: Acknowledge the creep potential of pure PTFE and specify a filled or reinforced grade to ensure a stable, long-term seal.

By understanding both its powerful advantages and its specific mechanical limitations, you can confidently deploy PTFE to achieve a reliable, long-lasting seal in your most demanding applications.

Summary Table:

| Advantage | Key Benefit | Ideal For |

|---|---|---|

| Chemical Inertness | Resists acids, bases, solvents | Chemical processing, labs |

| Temperature Stability | Performs from -200°C to +260°C | Cryogenic to high-heat systems |

| Purity & Compliance | Non-contaminating, FDA-compliant | Pharma, food, semiconductor |

| Surface Properties | Non-stick, low friction | Easy cleaning, dynamic seals |

Need a reliable PTFE sealing solution for your demanding application?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including precision ring gaskets, seals, and custom fabrications. Whether you're in the semiconductor, medical, pharmaceutical, or industrial sector, our expertise ensures you get a seal that delivers unmatched chemical resistance, thermal stability, and purity.

We provide solutions from prototype to high-volume production, prioritizing precision and reliability. Let our team help you select or custom-design the perfect PTFE gasket for your specific needs.

Contact KINTEK today for a consultation and quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- Why is PTFE's low friction coefficient advantageous for seals? Boost Efficiency & Reduce Wear

- Why are PTFE lined valves non-reactive with aggressive chemicals? The Molecular Shield Explained

- What are the key properties of PTFE that benefit bellows and diaphragms? Achieve Unmatched Reliability in Harsh Environments

- Why is it important to consider the whole lifecycle cost when evaluating Teflon gland packing? Uncover the True Cost of Ownership

- What are the advantages of Teflon washers? Achieve Superior Performance in Harsh Environments

- What are the different forms of PTFE used for manufacturing gaskets and seals? Choose the Right Material for Your Application

- What are the most suitable PTFE grades for CNC machined parts? Achieve Optimal Performance and Durability

- What is Teflon AF and what are its optical properties? Achieve Superior Optical Clarity with UV Resistance