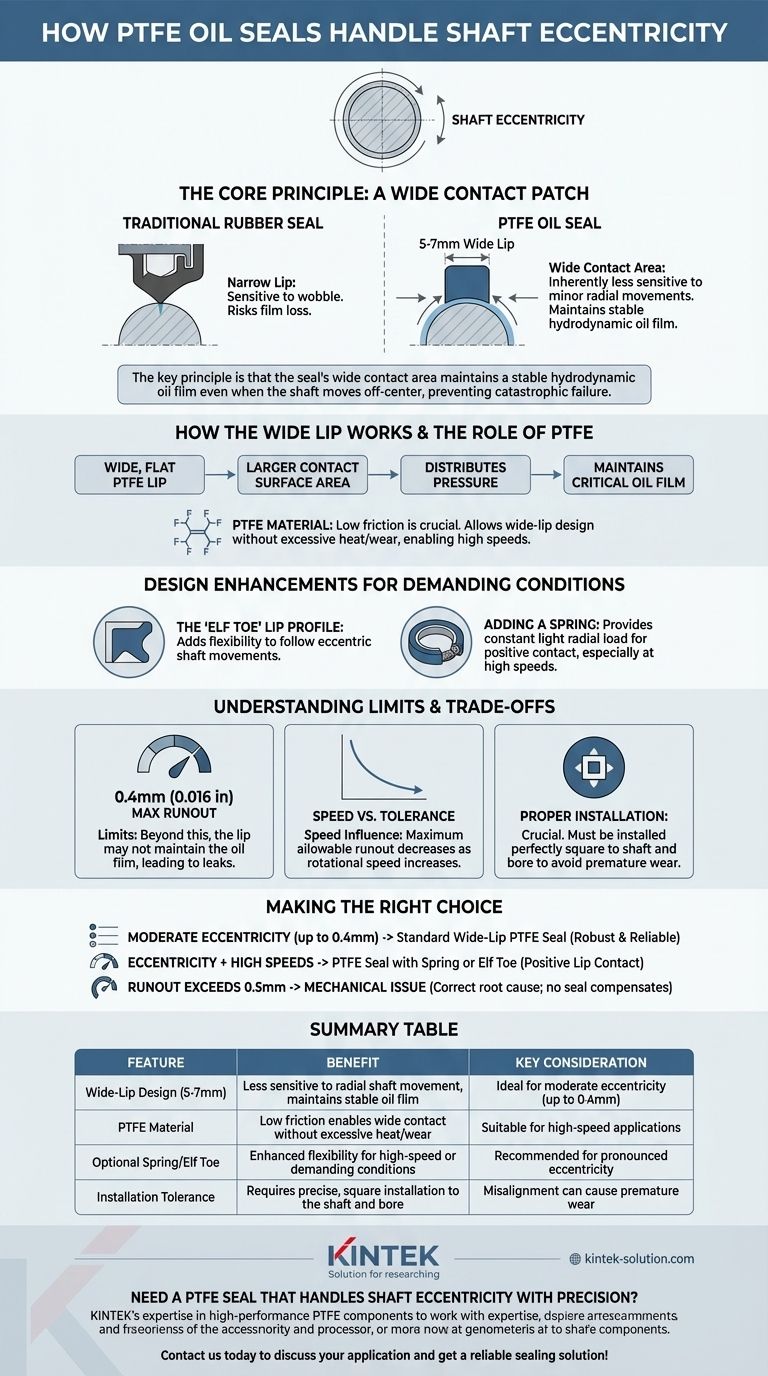

At its core, a PTFE oil seal's ability to handle shaft eccentricity comes from its signature wide-lip design. Unlike a traditional rubber seal that relies on a sharp, flexible point of contact, a PTFE seal uses a broad contact patch, typically 5-7mm wide, which is inherently less sensitive to minor radial shaft movements.

The key principle is that the seal's wide contact area maintains a stable hydrodynamic oil film even when the shaft moves off-center, preventing the catastrophic loss of sealing that would occur with a narrow-lipped seal.

The Core Principle: A Wide Contact Patch

The design philosophy behind a PTFE seal is fundamentally different from that of a traditional elastomeric (rubber) seal. This difference is central to its performance under eccentric conditions.

How the Wide Lip Works

A standard rubber seal uses a sharp, spring-loaded lip to create a high-pressure, narrow sealing line. This design is very effective for a perfectly centered shaft but can struggle to maintain contact if the shaft wobbles.

A PTFE seal, in contrast, uses a wide, flat lip that is precisely machined. This creates a broader contact band against the shaft, distributing pressure over a larger surface area.

Maintaining the Hydrodynamic Film

All seals ride on a micro-thin layer of lubricant called a hydrodynamic film. When a shaft has radial runout, it moves eccentrically.

The PTFE seal's wide lip ensures that even as the shaft moves, a sufficient portion of the lip remains in the optimal position to maintain this critical oil film. The seal doesn't have to "chase" the shaft's position as aggressively as a narrow seal would.

The Role of PTFE Material

The low-friction nature of Polytetrafluoroethylene (PTFE) is crucial. A wide contact patch made from a higher-friction material would generate excessive heat and wear.

PTFE allows for this wide-lip design without a significant thermal penalty, enabling it to function reliably at high speeds even with the larger surface contact.

Design Enhancements for Demanding Conditions

For applications with more pronounced eccentricity or higher speeds, the basic wide-lip design can be modified to improve its performance further.

The 'Elf Toe' Lip Profile

To add flexibility, the lip can be machined with a special profile, sometimes called an 'elf toe'. This modification provides a slight increase in the lip's ability to flex and follow the dynamic movements of an eccentric shaft.

Adding a Spring for Positive Contact

While many PTFE seals are engineered to function without a spring, one can be incorporated.

A small garter spring adds a constant, light radial load to the lip. This ensures the sealing surface maintains positive contact with the shaft, especially during high-speed rotations where runout can become more challenging to manage.

Understanding the Limits and Trade-offs

While robust, the PTFE seal is not a solution for excessive mechanical problems. Understanding its operational limits is critical for reliable performance.

Defining the Operating Limits

A well-designed PTFE seal can typically handle a radial runout of up to 0.4mm (approximately 0.016 inches). Beyond this point, the lip may be unable to maintain the oil film, leading to leaks.

The Influence of Rotational Speed

The amount of eccentricity a seal can tolerate is inversely related to shaft speed. At higher RPMs, the lip has less time to react to the shaft's movement.

Therefore, the maximum allowable runout may decrease as rotational speed increases. A runout of 0.4mm might be acceptable at 1,000 RPM but could cause failure at 5,000 RPM.

The Need for Proper Installation

The wide lip design is less forgiving of installation errors. The seal must be installed perfectly square to the shaft and bore.

Any initial misalignment can cause uneven pressure on the contact band, leading to premature wear and leakage, completely negating the benefits of the design.

Making the Right Choice for Your Application

Selecting the correct seal requires matching its capabilities to your specific operating conditions.

- If your primary focus is moderate eccentricity (up to 0.4mm): A standard wide-lip PTFE seal is an excellent choice, offering a robust and reliable solution.

- If you have both eccentricity and high speeds: Consider a PTFE seal with a spring-energized or 'elf toe' design to ensure positive lip contact.

- If your runout exceeds 0.5mm: The root cause is a mechanical issue that must be corrected. No standard lip seal can reliably compensate for such significant shaft displacement.

By understanding the function of the wide lip, you can confidently specify PTFE seals for applications where minor shaft eccentricity is an expected operating condition.

Summary Table:

| Feature | Benefit | Key Consideration |

|---|---|---|

| Wide-Lip Design (5-7mm) | Less sensitive to radial shaft movement, maintains stable oil film | Ideal for moderate eccentricity (up to 0.4mm) |

| PTFE Material | Low friction enables wide contact without excessive heat/wear | Suitable for high-speed applications |

| Optional Spring/Elf Toe | Enhanced flexibility for high-speed or demanding conditions | Recommended for pronounced eccentricity |

| Installation Tolerance | Requires precise, square installation to the shaft and bore | Misalignment can cause premature wear |

Need a PTFE Seal That Handles Shaft Eccentricity with Precision?

KINTEK specializes in manufacturing high-performance PTFE components, including seals, liners, and labware, for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in precision production and custom fabrication—from prototypes to high-volume orders—ensures you get a seal designed to thrive in your specific operating conditions.

Contact us today to discuss your application and get a reliable sealing solution!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Crucibles for Laboratory and Industrial Applications

People Also Ask

- In what applications are PTFE liners commonly used? Critical Solutions for Harsh Environments

- Can PTFE washers be customized? Get a Perfect Fit for Your Specific Application

- Why are PTFE ball valves not recommended for slurries? Prevent Abrasive Damage and Valve Failure

- Where are PTFE energized seals typically used in cryogenic applications? Critical Seals for LNG & Aerospace

- What are the unique features of PTFE Lined Pressure Seal Valves? The Ultimate Solution for High-Pressure, Corrosive Applications

- What are the limitations of PTFE fasteners? Key Weaknesses in Strength, Creep, and Cost

- Why are PTFE washers suitable for harsh environments? Unmatched Chemical & Temperature Resistance

- Why are PTFE sheets used in the medical industry? For Biocompatibility, Inertness & Low Friction