At its core, Polytetrafluoroethylene (PTFE) is used in the medical industry because of its unique combination of three critical properties. It is highly biocompatible, meaning it does not react with human tissue; it is almost completely chemically inert, so it resists degradation from bodily fluids and sterilizing agents; and it has an extremely low coefficient of friction, making it one of the slickest materials known. This triad of characteristics makes it invaluable for applications ranging from life-saving implants to high-performance surgical tools.

The central reason for PTFE's prevalence in medicine is not just that it is safe, but that its distinct physical properties actively solve fundamental challenges in patient care, such as minimizing tissue trauma, preventing infection, and ensuring the long-term reliability of implanted devices.

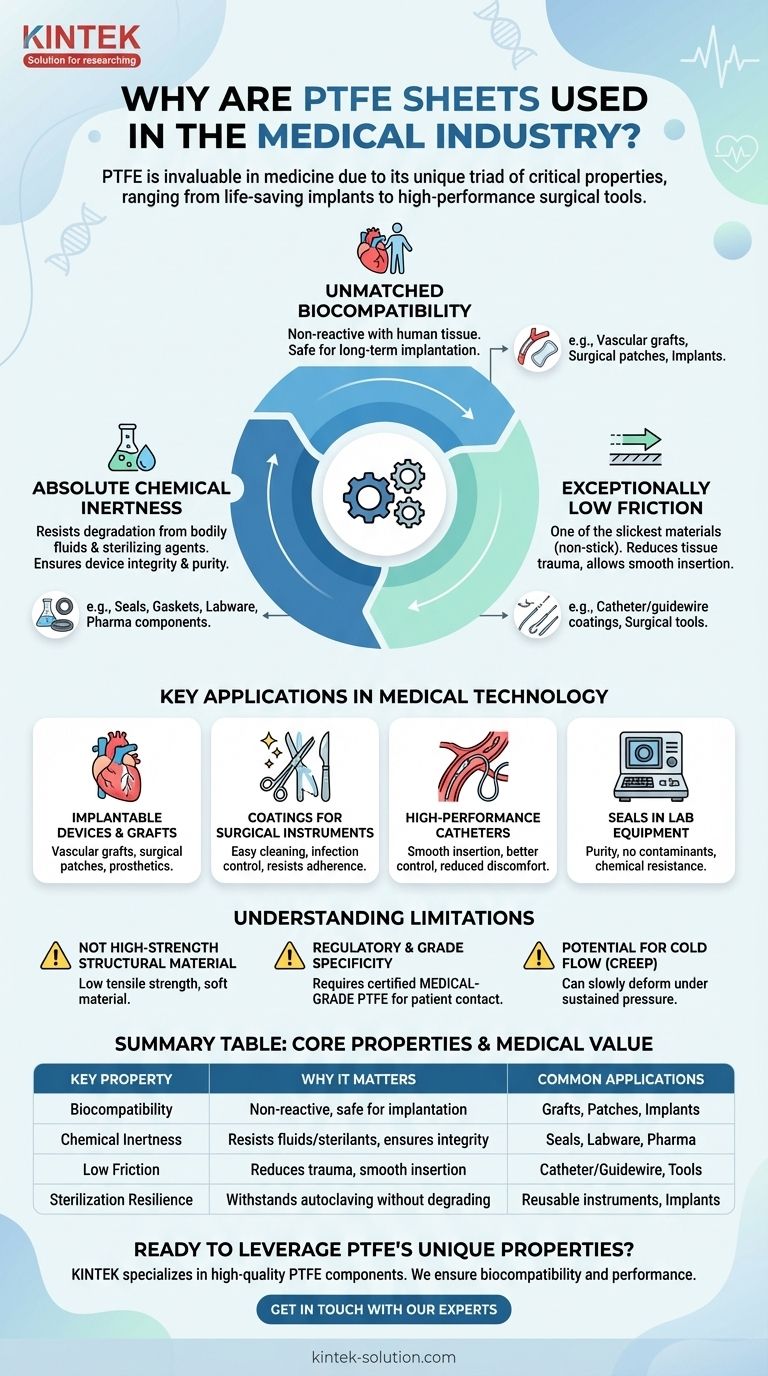

The Core Properties Driving Medical Adoption

The selection of any material for medical use is a rigorous process. PTFE consistently meets the demanding criteria because its inherent molecular structure gives it a powerful advantage.

Unmatched Biocompatibility

Biocompatibility is the single most important prerequisite for a medical material. It means the material can exist within a biological system without causing a harmful or immunological response.

PTFE is exceptionally non-reactive when introduced into the human body, which is why it's a trusted material for devices intended for long-term implantation.

Absolute Chemical Inertness

The medical environment is chemically aggressive, involving everything from bodily fluids to harsh sterilization chemicals. PTFE is resistant to virtually all common chemicals and solvents.

This inertness ensures that devices made from PTFE will not break down over time, leach harmful substances, or react with medications, guaranteeing both device integrity and patient safety.

Exceptionally Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This "non-stick" quality is a significant functional advantage.

For instruments like catheters and guidewires, a PTFE coating allows for smoother insertion and navigation through blood vessels. This minimizes tissue damage, reduces patient discomfort, and lowers the risk of complications.

Resilience to Sterilization

Medical devices must be sterile to prevent infection. PTFE's high thermal stability and chemical resistance allow it to withstand common sterilization methods, including autoclaving.

This ensures that PTFE components can be reliably sterilized without degrading their physical properties or performance, a critical requirement for reusable instruments and implantable devices.

Key Applications in Medical Technology

PTFE's properties translate directly into solutions for a wide range of medical and laboratory challenges.

Implantable Devices and Grafts

Because of its superior biocompatibility, PTFE is frequently used for implants that remain in the body. Common examples include vascular grafts to bypass or replace diseased arteries, surgical patches for tissue repair, and even some joint prosthetics.

Coatings for Surgical Instruments

Surgical instruments coated with PTFE resist the adherence of blood and tissue. This property makes them significantly easier to clean and sterilize effectively, playing a direct role in infection control protocols.

High-Performance Catheters and Guidewires

The ultra-low friction of PTFE is essential for intravascular devices. A thin coating on a guidewire or catheter dramatically reduces the force needed for insertion and maneuvering, providing physicians with better control and improving patient outcomes.

Seals and Components in Lab Equipment

In pharmaceutical manufacturing and diagnostic laboratories, purity is paramount. PTFE's chemical inertness makes it the ideal material for seals, gaskets, and tubing, ensuring that no contaminants are leached into sensitive processes or samples.

Understanding the Limitations and Considerations

While highly versatile, PTFE is not a universal solution. An objective assessment requires understanding its trade-offs.

Not a High-Strength Structural Material

In its pure form, PTFE is a relatively soft material with low tensile strength. It is not suitable for load-bearing applications unless it is reinforced with other materials like glass fiber or carbon.

Regulatory and Grade Specificity

Not all PTFE is created equal. Applications involving direct patient contact, especially implantation, require a specific medical-grade PTFE that has undergone rigorous testing and certification to ensure its purity and biocompatibility. Standard industrial-grade PTFE is not acceptable.

Potential for Cold Flow (Creep)

Under sustained pressure, PTFE can slowly deform over time, a phenomenon known as "creep" or "cold flow." This must be accounted for in the design of components like seals and gaskets that are under constant compressive loads.

Making the Right Choice for Your Goal

The decision to use PTFE should be directly tied to the primary goal of the medical device or component.

- If your primary focus is patient safety and long-term implantation: You must source certified, medical-grade PTFE to leverage its unmatched biocompatibility and chemical inertness for devices like vascular grafts and surgical patches.

- If your primary focus is enhancing device performance and user experience: Capitalize on PTFE's low-friction properties by using it as a coating for catheters, guidewires, and surgical tools to ensure smoother operation and minimize tissue trauma.

- If your primary focus is process purity and reliability: Employ PTFE for its chemical resistance in seals, gaskets, and fluid-handling components within pharmaceutical and laboratory equipment to prevent contamination and ensure consistent performance.

Ultimately, PTFE's unique combination of inert safety and functional performance has solidified its role as a cornerstone material in modern medical innovation.

Summary Table:

| Key Property | Why It Matters in Medicine | Common Applications |

|---|---|---|

| Biocompatibility | Non-reactive with human tissue; safe for long-term implantation. | Vascular grafts, surgical patches, implants. |

| Chemical Inertness | Resists bodily fluids & sterilants; ensures device integrity & purity. | Seals, gaskets, labware, pharmaceutical components. |

| Low Friction | Reduces tissue trauma; allows smooth insertion of instruments. | Catheter/guidewire coatings, surgical tools. |

| Sterilization Resilience | Withstands autoclaving & other methods without degrading. | Reusable surgical instruments, implantable devices. |

Ready to leverage PTFE's unique properties for your medical or lab application?

KINTEK specializes in the precision manufacturing of high-quality PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. We ensure every part meets stringent requirements for biocompatibility and performance, offering custom fabrication from prototypes to high-volume orders.

Contact us today to discuss how our PTFE solutions can enhance the safety, reliability, and performance of your products.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection

- When and by whom was PTFE discovered? A Tale of Accidental Innovation