Yes, PTFE washers are highly customizable. Beyond selecting standard English or metric units, they can be precisely manufactured to your specific dimensional and thickness requirements, produced in various colors, and even supplied with functional additions like a pre-applied pressure-sensitive adhesive backing.

The crucial takeaway is that PTFE is not a material you must design around; it is a material that can be precisely machined and tailored to meet the specific demands of your application, from dimensions and tolerances to functional enhancements.

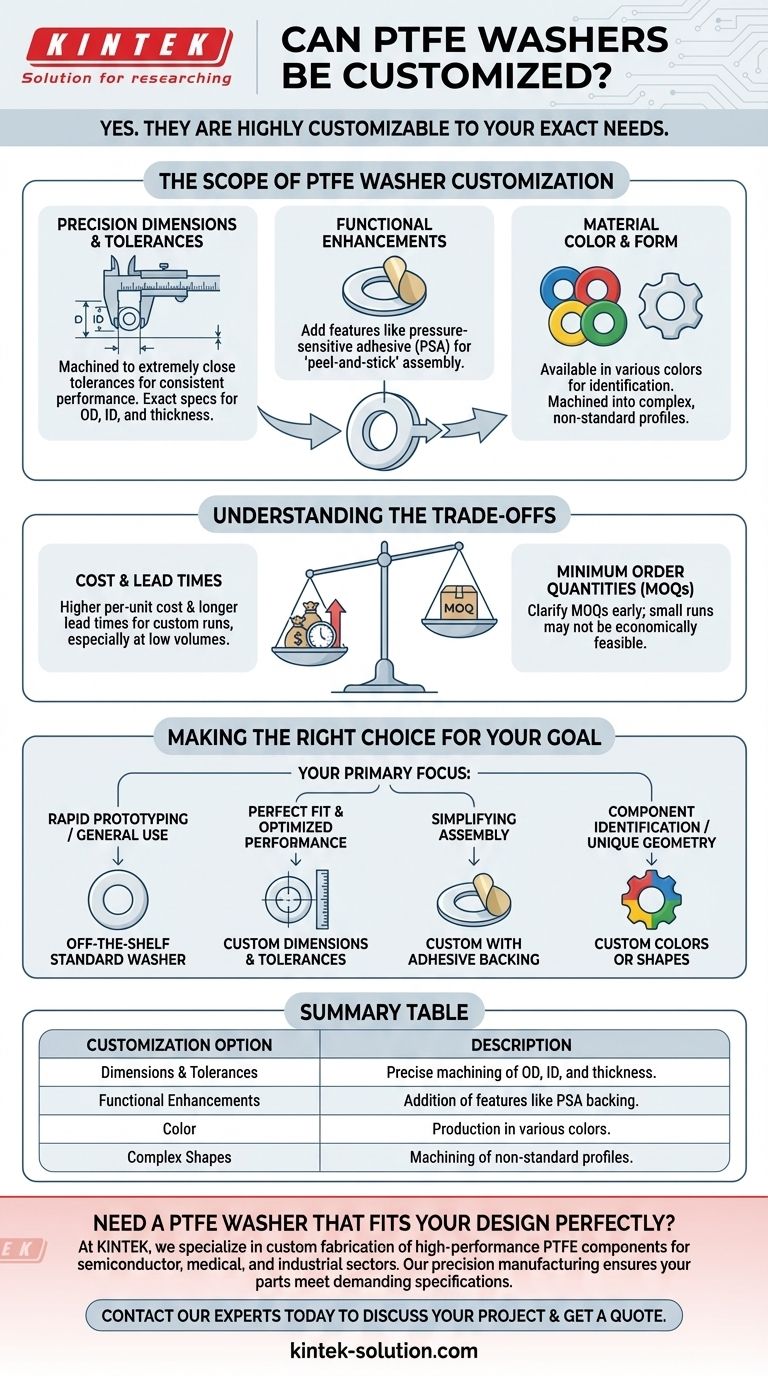

The Scope of PTFE Washer Customization

When sourcing PTFE components, it's helpful to think of a standard washer as just the starting point. The machinability of PTFE allows for a wide range of modifications to solve specific engineering problems.

Precision Dimensions and Tolerances

Your primary reason for customization will likely be achieving a perfect fit. PTFE can be machined on CNC lathes to extremely close tolerances, ensuring consistent performance in demanding applications. This applies to every dimension, including outer diameter, inner diameter, and thickness.

While standard sizes are readily available, custom diameters can range from fractions of an inch to several feet, with thicknesses specified to your exact need.

Functional Enhancements

Customization extends beyond simple dimensions. Functional features can be added to simplify assembly or improve performance in the final product.

The most common enhancement is the application of a pressure-sensitive adhesive (PSA) backing. This turns the washer into a "peel-and-stick" component, ensuring it stays in place during assembly and operation.

Material Color and Form

For applications requiring color-coding, component identification, or specific aesthetic properties, PTFE washers can be produced in various colors.

Furthermore, because they are machined, the term "washer" can be expanded to include more complex shapes and forms. If your design requires a non-standard profile or a shape that is not a simple flat ring, it can likely be produced from PTFE stock.

Understanding the Trade-offs

While the customization possibilities are extensive, it's critical to consider the practical implications before placing an order. Objectivity requires acknowledging the trade-offs involved.

Cost vs. Volume

Custom-machined parts almost always have a higher per-unit cost than off-the-shelf components, especially at low volumes. The setup, tooling, and programming for a custom run create overhead that must be factored in. As the production volume increases, the per-unit cost typically decreases.

Lead Times

Standard washers are often in stock and can be shipped immediately. Custom manufacturing, by contrast, requires longer lead times. This includes the time needed for design finalization, machine setup, production, and quality control. This must be accounted for in your project schedule.

Minimum Order Quantities (MOQs)

Many manufacturers will have a minimum order quantity for a custom run. It is often not economically feasible to set up machinery for just a handful of parts. Always clarify the MOQ with your supplier early in the design process to ensure it aligns with your project's needs.

Making the Right Choice for Your Goal

Selecting the right washer depends entirely on your project's balance of precision, cost, and speed.

- If your primary focus is rapid prototyping or general-purpose use: An off-the-shelf standard washer is the most efficient and cost-effective solution.

- If your primary focus is a perfect fit and optimized performance: Custom dimensions and tight tolerances are essential and well worth the investment.

- If your primary focus is simplifying and speeding up your assembly process: A custom washer with an adhesive backing can provide significant value.

- If your primary focus is component identification or a unique geometry: Custom colors or machined shapes are the ideal approach.

Ultimately, the customizability of PTFE ensures you can source a component that solves your exact problem, rather than compromising your design to fit a standard part.

Summary Table:

| Customization Option | Description |

|---|---|

| Dimensions & Tolerances | Precise machining of OD, ID, and thickness to exact specifications. |

| Functional Enhancements | Addition of features like pressure-sensitive adhesive (PSA) backing. |

| Color | Production in various colors for identification or aesthetics. |

| Complex Shapes | Machining of non-standard profiles beyond simple flat rings. |

Need a PTFE washer that fits your design perfectly?

At KINTEK, we specialize in custom fabrication of high-performance PTFE components, including seals, liners, and labware. Whether you require a prototype or a high-volume production run for the semiconductor, medical, laboratory, or industrial sectors, our precision manufacturing ensures your parts meet the most demanding specifications.

Contact our experts today to discuss your project and receive a quote tailored to your needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications