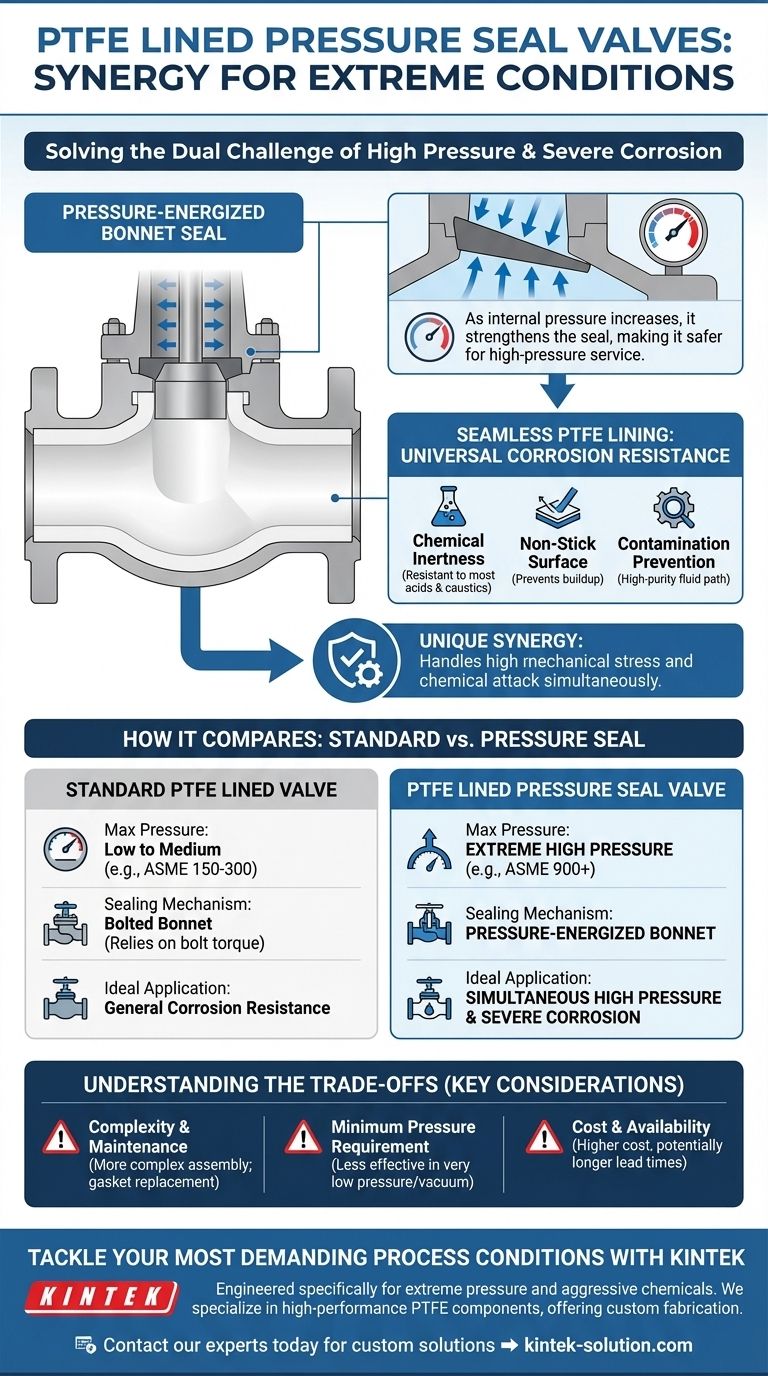

At its core, a PTFE Lined Pressure Seal Valve combines two distinct technologies to solve one of the most difficult industrial challenges. Its unique feature is the synergy between a pressure-energized bonnet seal for handling extreme pressures and a seamless PTFE lining for providing universal corrosion resistance against aggressive chemicals.

The critical takeaway is that this valve type isn't just a PTFE-coated valve; it's a specialized design where the internal system pressure itself is used to strengthen the main body-bonnet seal, making it ideal for applications where both high pressure and severe corrosion are present simultaneously.

Deconstructing the "PTFE Lined Pressure Seal" Design

To understand this valve, you must analyze its two primary components separately: the sealing mechanism and the protective lining. Each addresses a different aspect of a demanding process environment.

The Pressure Seal Bonnet: How It Works

The defining characteristic of a pressure seal valve is how it contains pressure. Unlike standard valves that rely entirely on bolts to squeeze a gasket (bolted bonnet), a pressure seal design uses the process pressure to its advantage.

As internal pressure increases, it pushes the bonnet upwards against a specialized gasket, which is wedged between the bonnet and the tapered valve body. This force energizes the gasket, creating an increasingly tight seal.

The bolts on top are primarily for initial seating and creating a seal at low pressures. The higher the system pressure, the more robust the seal becomes, making it inherently safer for high-pressure service.

The PTFE Lining: Total Corrosion Resistance

The "PTFE Lined" aspect refers to the thick, seamless layer of Polytetrafluoroethylene that completely isolates the process fluid from the valve's metal body (typically carbon or stainless steel).

This lining provides several key benefits:

- Chemical Inertness: PTFE is resistant to nearly all industrial chemicals, acids, and caustics.

- Non-Stick Surface: The low-friction, non-stick nature of PTFE prevents media buildup, reducing maintenance and ensuring smooth operation.

- Contamination Prevention: It ensures a high-purity fluid path, critical in industries like pharmaceuticals and food processing.

The Synergy of Both Features

The combination is what makes this valve unique. It is specified for applications where a standard pressure seal valve would corrode or a standard lined valve could not withstand the pressure. It solves the dual problem of mechanical stress and chemical attack.

How It Compares to Other PTFE Lined Valves

Not all lined valves are built for the same purpose. The pressure seal design places this valve in a class of its own for high-energy systems.

vs. Lined Gate & Plug Valves

PTFE lined gate and plug valves are excellent for providing a tight, corrosion-resistant shutoff. However, they almost always use a traditional bolted bonnet, which limits their suitability for the extreme pressures (e.g., ASME Class 900 and above) where pressure seal designs excel.

vs. Lined Butterfly Valves

Lined butterfly valves are designed for flow regulation (throttling) and are lightweight and economical, especially in large pipe diameters. They are not intended for the ultra-high-pressure applications that demand a pressure seal bonnet.

vs. Lined Check Valves

These valves serve a completely different purpose: preventing reverse flow. While they benefit from a PTFE lining for corrosion resistance, their function is passive and unrelated to the active shutoff or control provided by a pressure seal gate or globe valve.

Understanding the Trade-offs

No design is without its compromises. Acknowledging the limitations of this specialized valve is key to proper application.

Complexity and Maintenance

The pressure seal bonnet is more complex to assemble and disassemble than a simple bolted bonnet. The sealing gasket, often made of flexible graphite or expanded PTFE (ePTFE), requires careful handling and is typically replaced during servicing.

Minimum Pressure Requirement

Because the seal is pressure-assisted, these valves may be less effective in very low-pressure or vacuum conditions. The initial bolt torque provides a seal, but the design is optimized for environments where significant pressure is present.

Cost and Availability

This is a high-performance, specialized valve. The combination of a pressure seal body and a high-integrity PTFE lining results in a significantly higher cost and potentially longer lead times compared to more common valve types.

Making the Right Choice for Your System

Selecting the correct valve requires a clear understanding of your primary operational challenge: pressure, corrosion, or both.

- If your primary focus is extreme pressure AND corrosive media: The PTFE Lined Pressure Seal Valve is specifically engineered for this punishing combination, offering safety and material compatibility.

- If your primary focus is general corrosion resistance in low-to-medium pressure: Standard PTFE lined ball, plug, or butterfly valves are more cost-effective and simpler to maintain.

- If your primary focus is simple on/off service for non-corrosive, high-pressure fluids: A standard, unlined pressure seal valve is the correct and more economical choice.

Understanding this synergy between pressure handling and chemical resistance is key to specifying a valve that ensures both safety and longevity in your most demanding applications.

Summary Table:

| Feature | Standard PTFE Lined Valve | PTFE Lined Pressure Seal Valve |

|---|---|---|

| Max Pressure Rating | Low to Medium (e.g., ASME Class 150-300) | Extreme High Pressure (e.g., ASME Class 900+) |

| Primary Sealing Mechanism | Bolted Bonnet | Pressure-Energized Bonnet |

| Ideal Application | General Corrosion Resistance | Simultaneous High Pressure & Severe Corrosion |

| Best For | Chemical processing, water treatment | Power generation, oil & gas, severe chemical processes |

Tackle Your Most Demanding Process Conditions with KINTEK

Does your application involve a punishing combination of extreme pressure and aggressive, corrosive chemicals? Standard valves may fail, but a PTFE Lined Pressure Seal Valve is engineered specifically for this challenge.

At KINTEK, we specialize in manufacturing high-performance PTFE components, including custom-fabricated seals, liners, and labware for the semiconductor, medical, laboratory, and industrial sectors. We understand the critical need for precision and reliability in harsh environments.

Let us provide you with a valve solution that ensures safety, longevity, and peak performance. We offer custom fabrication from prototypes to high-volume orders.

Contact our experts today to discuss your specific requirements ➔ Get in Touch

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are the key properties of PTFE that benefit gland packing? Achieve Superior Sealing Performance

- What materials are used in PTFE lined butterfly valves to ensure resistance to corrosion and leakage? The Core Components Explained

- What makes PTFE bushes suitable for high-temperature applications? Unlock Reliability in Extreme Heat

- How does the free extrusion process enhance the yield strength of PTFE liners? Achieve Superior Axial Strength

- Why are PTFE-coated O-rings particularly suitable for food processing applications? Ensure Ultimate Hygiene & Safety

- What design considerations are important when using PTFE seals? Optimize Your Sealing System Design

- What are the symptoms of a leaking PTFE butterfly valve? Identify External & Internal Leaks

- What makes PTFE-lined butterfly valves durable? Unmatched Chemical & Thermal Resistance