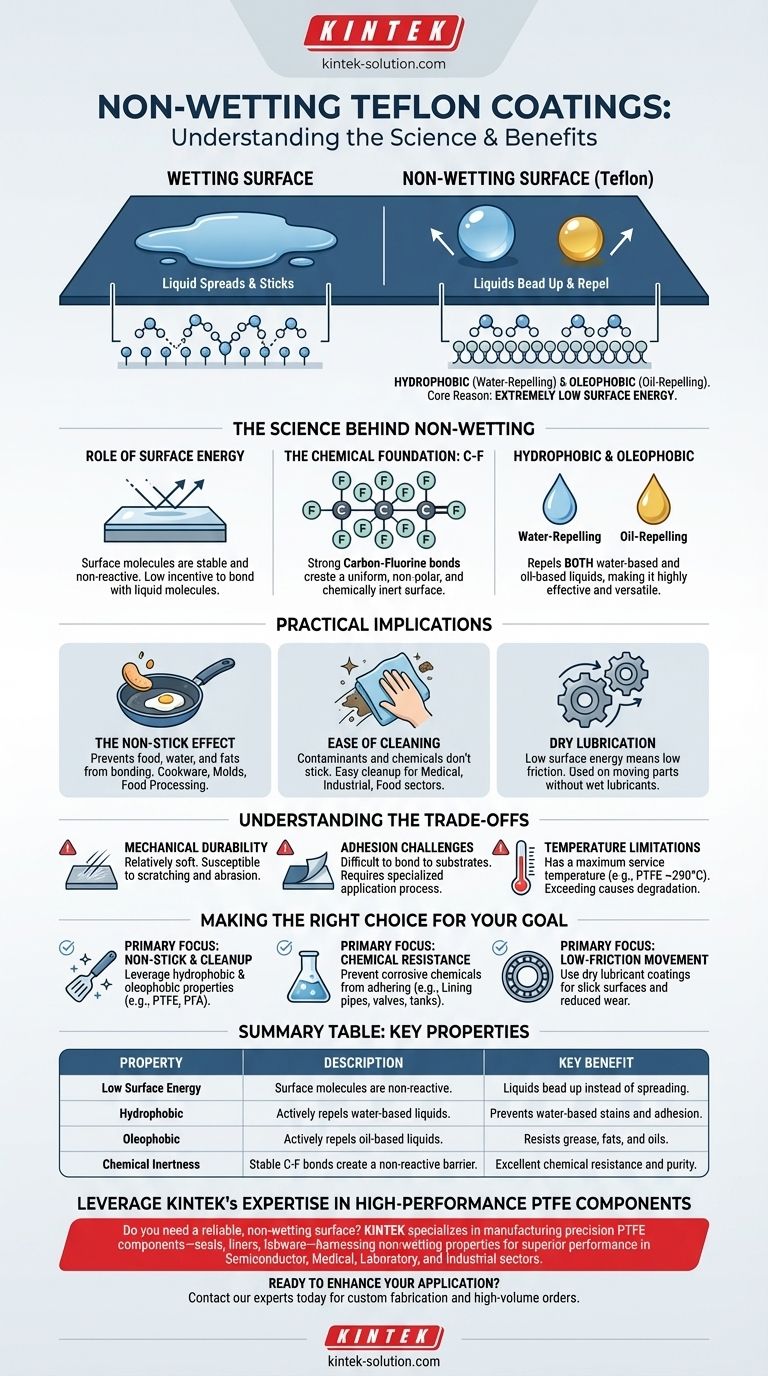

To say a Teflon coating is "non-wetting" means that it actively repels liquids, including both water and oils. Instead of spreading out and "wetting" the surface, liquids are forced to bead up into distinct droplets due to a property called low surface energy. This characteristic makes Teflon both hydrophobic (water-repelling) and oleophobic (oil-repelling).

The core reason Teflon is non-wetting is its extremely low surface energy. This property, derived from its stable carbon-fluorine chemical structure, makes liquids more attracted to their own molecules than to the Teflon surface, causing them to retract into beads.

The Science Behind Non-Wetting

To understand why Teflon works this way, we need to look at its fundamental physical and chemical properties. It isn't a simple barrier; it's a result of forces at the molecular level.

The Role of Surface Energy

Surface energy is a measure of how much a material's surface molecules want to interact with other things. High-energy surfaces are reactive and easily wetted, while low-energy surfaces are stable and non-reactive.

Teflon possesses one of the lowest surface energies of any known solid. This means its surface is extremely stable and has very little incentive to bond with or attract the molecules of a liquid placed upon it.

The Chemical Foundation: Carbon and Fluorine

Teflon's chemical structure consists of a long chain of carbon atoms completely surrounded by fluorine atoms. This Carbon-Fluorine (C-F) bond is exceptionally strong and stable.

The fluorine atoms create a uniform, non-polar, and chemically inert surface. There is almost no electrical charge for liquid molecules to grab onto, effectively creating a non-interactive barrier.

Hydrophobic and Oleophobic Properties

A material that repels water is hydrophobic. A material that repels oil is oleophobic.

While many materials are hydrophobic, very few are also oleophobic. Teflon's ability to repel both water-based and oil-based liquids is what makes its non-wetting capability so effective and versatile.

Practical Implications of a Non-Wetting Surface

This single property of being non-wetting is the source of Teflon's most famous characteristics and drives its use across countless industries.

The "Non-Stick" Effect

The most familiar application is in cookware. Because food contains both water and fats (oils), Teflon's ability to repel both prevents food from forming a bond with the pan's surface, allowing it to slide off easily.

Ease of Cleaning

The non-wetting property is synonymous with easy cleanup. Since contaminants, chemicals, and grime cannot effectively stick to the surface, they can be wiped away with minimal effort. This is critical in food processing, medical, and industrial applications.

Dry Lubrication

Specialized Teflon coatings are used as dry lubricants on moving parts. The low surface energy results in extremely low friction, allowing components to move smoothly without the need for wet oils or greases that can attract dirt and debris.

Understanding the Trade-offs

While its non-wetting properties are powerful, Teflon coatings are not without their limitations. Understanding these is key to using them effectively.

Mechanical Durability

The same chemical stability that makes Teflon non-stick also makes it a relatively soft material. Pure PTFE coatings can be susceptible to scratching and abrasion, which can compromise the non-wetting surface.

Adhesion Challenges

The very property that prevents things from sticking to Teflon also makes it difficult to get Teflon to stick to a substrate. Applying these coatings is a specialized industrial process requiring careful surface preparation to ensure a durable bond.

Temperature Limitations

While highly resistant to a wide range of temperatures, each type of Teflon coating has a maximum service temperature. For example, PTFE is stable up to around 290°C (554°F), while others like FEP have a lower limit. Exceeding this can cause the coating to degrade.

Making the Right Choice for Your Goal

The non-wetting characteristic can be leveraged for several different outcomes, and your primary goal should guide your choice.

- If your primary focus is non-stick performance and easy cleanup: The powerful hydrophobic and oleophobic nature of coatings like PTFE or PFA is exactly what you need for cookware, food processing equipment, or molds.

- If your primary focus is chemical resistance: The non-wetting surface prevents corrosive chemicals from adhering to and attacking the underlying material, making it ideal for lining pipes, valves, and tanks.

- If your primary focus is low-friction movement: Dry lubricant coatings that use PTFE's non-wetting nature provide a slick surface that reduces wear on moving parts without attracting contaminants.

Ultimately, understanding that "non-wetting" is a direct result of low surface energy allows you to predict and leverage Teflon's unique performance in any application.

Summary Table:

| Property | Description | Key Benefit |

|---|---|---|

| Low Surface Energy | Teflon's surface molecules are non-reactive. | Liquids bead up instead of spreading. |

| Hydrophobic | Actively repels water-based liquids. | Prevents water-based stains and adhesion. |

| Oleophobic | Actively repels oil-based liquids. | Resists grease, fats, and oils. |

| Chemical Inertness | Stable carbon-fluorine bonds create a non-reactive barrier. | Excellent chemical resistance and purity. |

Leverage KINTEK's Expertise in High-Performance PTFE Components

Do you need a reliable, non-wetting surface to solve a critical challenge in your industry? KINTEK specializes in manufacturing precision PTFE components—including custom seals, liners, and labware—that harness the power of non-wetting properties for superior performance.

We serve the semiconductor, medical, laboratory, and industrial sectors with custom fabrication from prototypes to high-volume orders, ensuring your components meet exact specifications for non-stick performance, chemical resistance, and low friction.

Ready to enhance your application with a trusted PTFE solution? Contact our experts today to discuss your project requirements and discover how we can add value to your operations.

Visual Guide

Related Products

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

People Also Ask

- What advantages do PTFE gaskets offer in terms of friction and wear? Achieve Low-Friction, Long-Lasting Seals

- What are spring-energized seals, and why are they used in extreme environments?

- How do composite bellows compare to PTFE bellows? Choose the Right Bellow for Your Application

- What industries benefit from using PTFE rod in bearings and bushings? Enhance Performance in Demanding Environments

- How does the melting point and thermal stability of PTFE impact its CNC machining? Mastering Heat Control for Precision

- What are the main types of CNC machining used for Teflon? Master Precision PTFE Parts Fabrication

- What long-term benefits do Teflon bearings provide? Slash Maintenance Costs & Boost Reliability

- What are the advantages of glass-filled Teflon balls? Enhanced Strength & Wear Resistance for Demanding Applications