Ultimately, the high melting point of PTFE is misleading. While the material won't melt during CNC machining, its excellent thermal stability is paired with a critical weakness: it softens and expands significantly with heat. This means the primary challenge isn't preventing melting, but managing the thermal deformation caused by cutting friction to maintain dimensional accuracy.

The core problem when machining PTFE is not its melting point, but its high rate of thermal expansion and tendency to soften. Success depends entirely on controlling heat at the cutting edge to prevent the material from deforming and compromising the final part's precision.

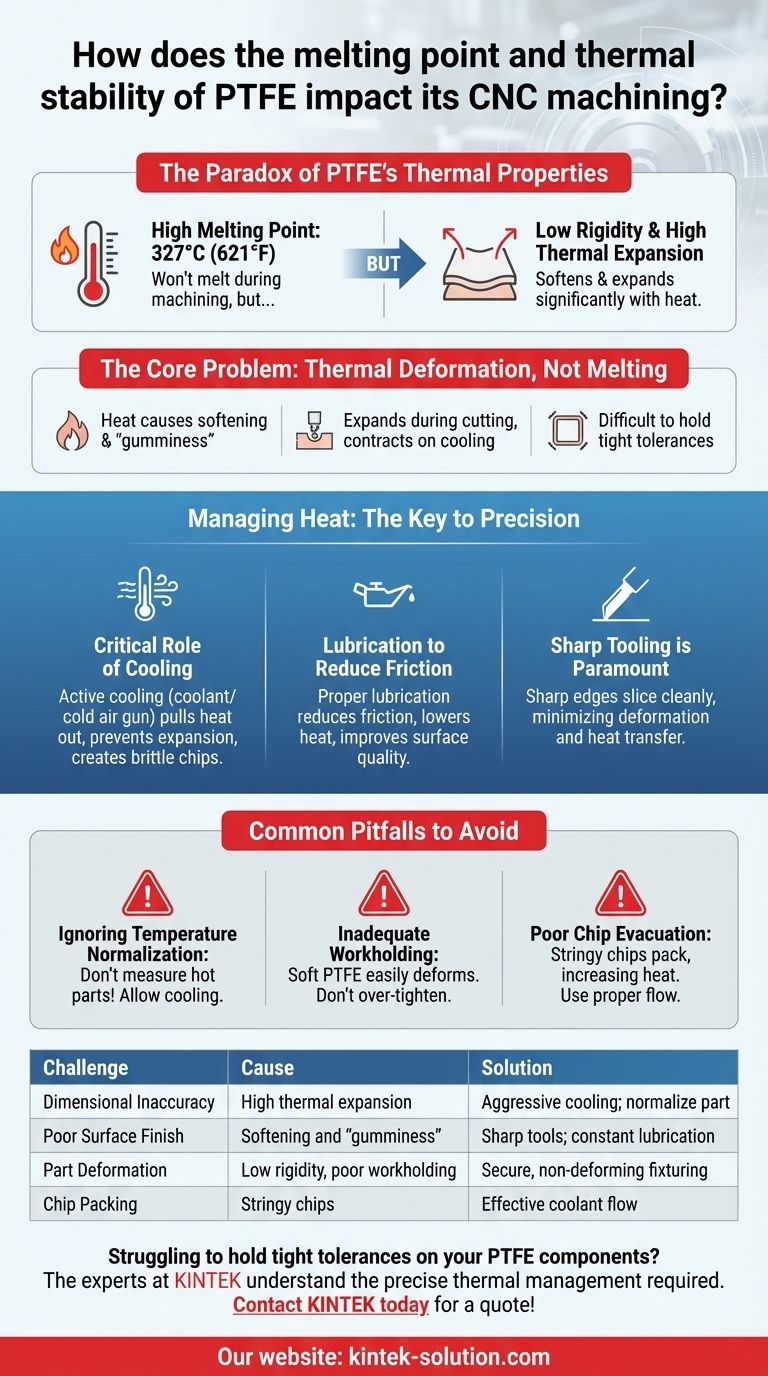

The Paradox of PTFE's Thermal Properties

PTFE's reputation for handling high temperatures is a major benefit in its final application, but it can create a false sense of security during the manufacturing process. The dynamics of CNC machining introduce factors that make heat a critical variable to control.

High Melting Point vs. Low Rigidity

PTFE has a very high melting point of 327°C (621°F) and can operate continuously at temperatures up to 260°C (500°F).

However, PTFE is also a very soft material with low rigidity. The friction from a cutting tool generates localized heat that, while far below the melting point, is more than enough to cause the material to soften, expand, and become "gummy."

This behavior leads to poor surface finishes and makes holding tight tolerances extremely difficult, as the part can deform under the pressure of the tool itself.

Thermal Expansion is the Real Enemy

The most significant challenge is PTFE's high coefficient of thermal expansion. As the material heats up from machining, it expands.

If a feature is machined to precise dimensions while the part is warm, it will contract as it cools, resulting in an undersized and out-of-spec component. This effect is the single most common cause of failure when machining PTFE to tight tolerances.

Managing Heat: The Key to Precision

Because thermal deformation is the central challenge, every aspect of the machining strategy must be oriented around minimizing and managing heat generation.

The Critical Role of Cooling

Active cooling is non-negotiable for precision work. Using a steady stream of coolant or a cold air gun directly at the point of contact is essential.

This serves two purposes: it pulls heat out of the workpiece to prevent thermal expansion, and it helps create more brittle chips that break away cleanly instead of wrapping around the tool.

Lubrication to Reduce Friction

Lubrication is key to reducing the source of heat in the first place: friction.

A proper coolant reduces friction between the cutting tool and the material, allowing for a cleaner shearing action. This not only keeps temperatures down but also improves the final surface quality.

Sharp Tooling is Paramount

Using extremely sharp cutting tools designed for soft plastics is crucial.

Dull tools don't cut; they plow through the material, generating immense friction and heat. A sharp edge slices cleanly, minimizing material deformation and ensuring that heat is carried away in the chip rather than transferred into the part.

Common Pitfalls to Avoid

Understanding the common failure modes is essential for developing a successful machining strategy for PTFE.

Ignoring Temperature Normalization

A frequent mistake is measuring the part for final inspection immediately after the last cut. The residual heat will cause it to be in an expanded state. The part must be allowed to cool and stabilize at room temperature before taking any critical measurements.

Inadequate Workholding

PTFE's softness makes it highly susceptible to being crushed or deformed by clamping pressure. Over-tightening a vise will distort the raw material, and any features machined into it will be inaccurate once the pressure is released. Fixturing must be secure but not deform the stock.

Poor Chip Evacuation

The soft, stringy chips produced by PTFE can easily wrap around the cutting tool and spindle. This "chip packing" increases friction, generates more heat, and can severely mar the part's surface finish. Proper coolant flow is essential for evacuating these chips from the cutting zone.

Making the Right Choice for Your Goal

Your machining strategy should adapt based on the most critical requirement for the final component.

- If your primary focus is dimensional accuracy: Prioritize aggressive cooling with a flood coolant or cold air gun and let the part fully normalize to room temperature before taking final measurements.

- If your primary focus is surface finish: Use extremely sharp, polished tools with a high-positive rake angle and ensure constant lubrication to achieve a clean shearing action rather than smearing.

- If your primary focus is production speed: Optimize speeds and feeds carefully; faster is not always better if it introduces excessive heat that ruins the part and requires rework.

Mastering PTFE machining comes down to one principle: control the heat, and you will control the part.

Summary Table:

| Challenge | Cause | Solution |

|---|---|---|

| Dimensional Inaccuracy | High thermal expansion from cutting heat | Aggressive cooling; allow part to normalize to room temp |

| Poor Surface Finish | Softening and "gumminess" from heat | Sharp, polished tools; constant lubrication |

| Part Deformation | Low rigidity and poor workholding | Secure, non-deforming fixturing |

| Chip Packing | Soft, stringy chips wrapping around tool | Effective coolant flow for chip evacuation |

Struggling to hold tight tolerances on your PTFE components? The experts at KINTEK understand the precise thermal management required for machining PTFE seals, liners, and labware. We specialize in custom fabrication from prototypes to high-volume orders for the semiconductor, medical, and laboratory industries. Let us apply our precision production expertise to your project.

Contact KINTEB today to discuss your specific requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems