In material science, the addition of a filler is designed to enhance specific properties of a base polymer. Glass-filled Teflon balls are a prime example of this, offering significantly improved mechanical characteristics over their virgin (unfilled) counterparts. The key advantages are superior wear resistance, increased compressive strength, lower deformation under load, and greater dimensional stability across a range of temperatures.

The choice between virgin and glass-filled Teflon is a classic engineering trade-off. While virgin Teflon excels in chemical purity and electrical insulation, adding glass fibers transforms it into a robust, load-bearing material suitable for high-stress mechanical systems where pure Teflon would deform or wear out prematurely.

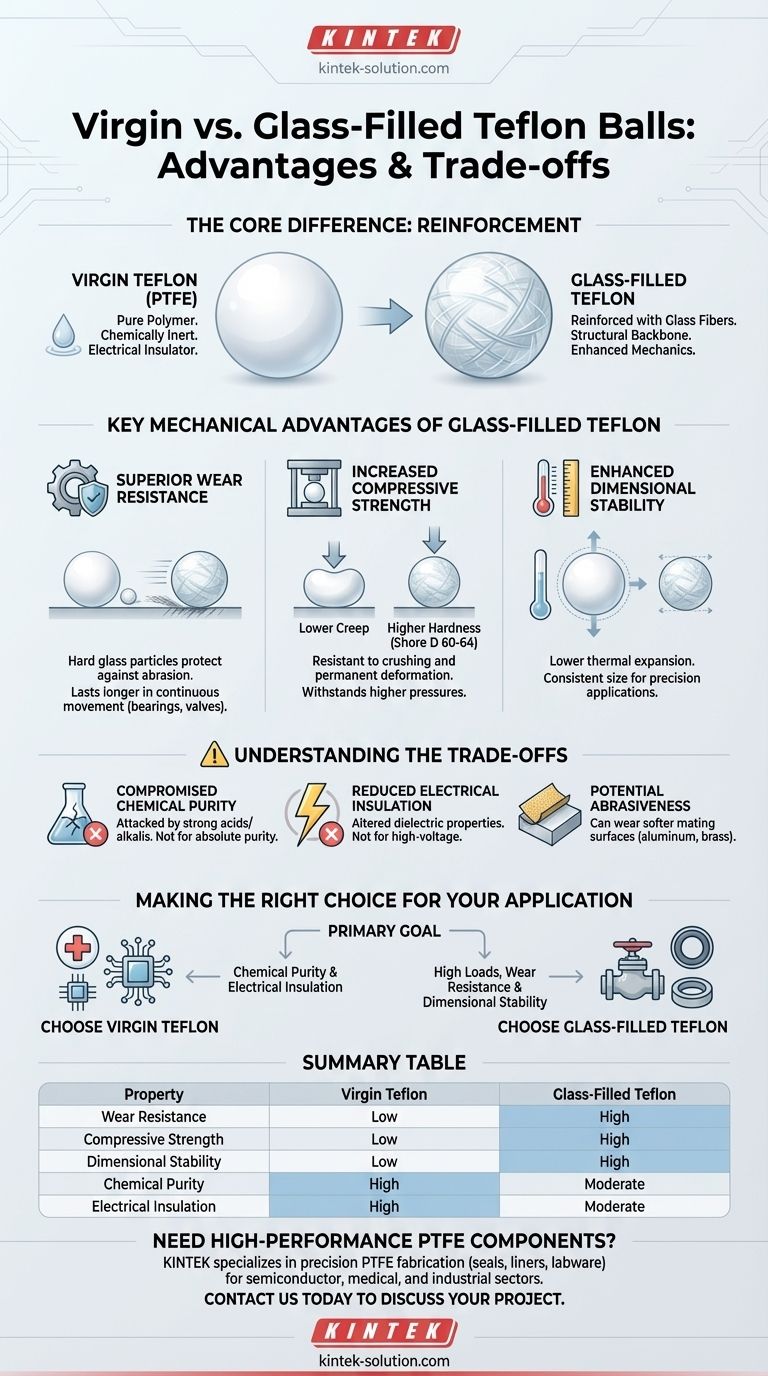

The Core Difference: Reinforcement with Glass Fiber

To understand the advantages, it's essential to first understand what distinguishes these two materials at a microscopic level.

What is "Virgin" Teflon?

Virgin Teflon, or Polytetrafluoroethylene (PTFE), is a pure, unfilled polymer.

It is renowned for its exceptional chemical inertness, extremely low coefficient of friction (making it very slippery), and superb performance as an electrical insulator.

The Role of Glass Filler

Glass-filled Teflon contains microscopic glass fibers or particles blended into the PTFE matrix.

These fibers act as a reinforcement, much like rebar strengthens concrete. The rigid glass provides a structural backbone within the softer Teflon base, which is the source of its enhanced mechanical properties.

Key Mechanical Advantages of Glass-Filled Teflon

The addition of glass fibers directly translates to superior performance in demanding physical applications.

Superior Wear Resistance

The hard glass particles protect the softer Teflon material from abrasion and friction.

This makes glass-filled balls last significantly longer in applications involving continuous movement, such as in bearings, check valves, and flow meters.

Increased Compressive Strength & Hardness

Glass-filled Teflon is far more resistant to being crushed or permanently deformed under heavy loads.

It has a higher hardness rating (typically Shore D 60-64 vs. 51-60 for virgin PTFE) and can withstand higher pressures without losing its shape. This property, known as lower "creep" or "cold flow," is critical for components under constant stress.

Enhanced Dimensional Stability

Pure Teflon tends to expand and contract noticeably with temperature changes.

Glass-filled Teflon has a lower coefficient of thermal expansion, meaning its size remains more consistent during temperature fluctuations. This ensures predictable performance and maintains tight tolerances in precision equipment.

Understanding the Trade-offs

While mechanically superior, glass-filled Teflon is not the right choice for every situation. Understanding its limitations is crucial for proper material selection.

Compromised Chemical Purity

The primary trade-off is a reduction in chemical inertness. While still highly resistant, the glass filler can be attacked by certain powerful chemicals, such as strong acids and alkalis, that virgin PTFE would easily resist.

This makes virgin Teflon the only choice for applications requiring absolute chemical purity, such as in the medical, pharmaceutical, or semiconductor industries.

Reduced Electrical Insulation

Virgin PTFE is one of the best electrical insulators available. The addition of glass fibers alters its dielectric properties.

While still a good insulator, glass-filled Teflon is not suitable for high-voltage or high-frequency applications where the premier insulating capability of virgin PTFE is required.

Potential for Abrasiveness

The hard glass fibers that provide excellent wear resistance can also be abrasive to softer mating surfaces.

Using glass-filled Teflon balls against soft metals like aluminum or brass can cause wear on those components over time. This must be considered in the overall system design.

Making the Right Choice for Your Application

Selecting the correct material requires a clear understanding of your primary operational goal.

- If your primary focus is electrical insulation or chemical purity: Virgin Teflon is the unambiguous choice, especially in food-grade, medical, or high-voltage electronic applications.

- If your primary focus is high loads and wear resistance: Glass-filled Teflon is superior for mechanical components like bearings, seals, and valve balls in industrial or petrochemical systems.

- If your primary focus is dimensional stability at varying temperatures: Glass-filled Teflon's lower thermal expansion makes it the more reliable option for precision applications where tight tolerances are critical.

By understanding these fundamental trade-offs, you can select the material that provides the precise performance characteristics your application demands.

Summary Table:

| Property | Virgin Teflon | Glass-Filled Teflon |

|---|---|---|

| Wear Resistance | Low | High |

| Compressive Strength | Low | High |

| Dimensional Stability | Low | High |

| Chemical Purity | High | Moderate |

| Electrical Insulation | High | Moderate |

Need High-Performance PTFE Components for Your Application?

KINTEK specializes in manufacturing precision PTFE components, including custom seals, liners, and labware. Whether your priority is the chemical purity of virgin PTFE or the mechanical strength of glass-filled variants, our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get the right material solution for the semiconductor, medical, laboratory, and industrial sectors.

Contact us today to discuss your project requirements and leverage our precision production capabilities!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE and Nitrile Diaphragm Pump Components for Demanding Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs