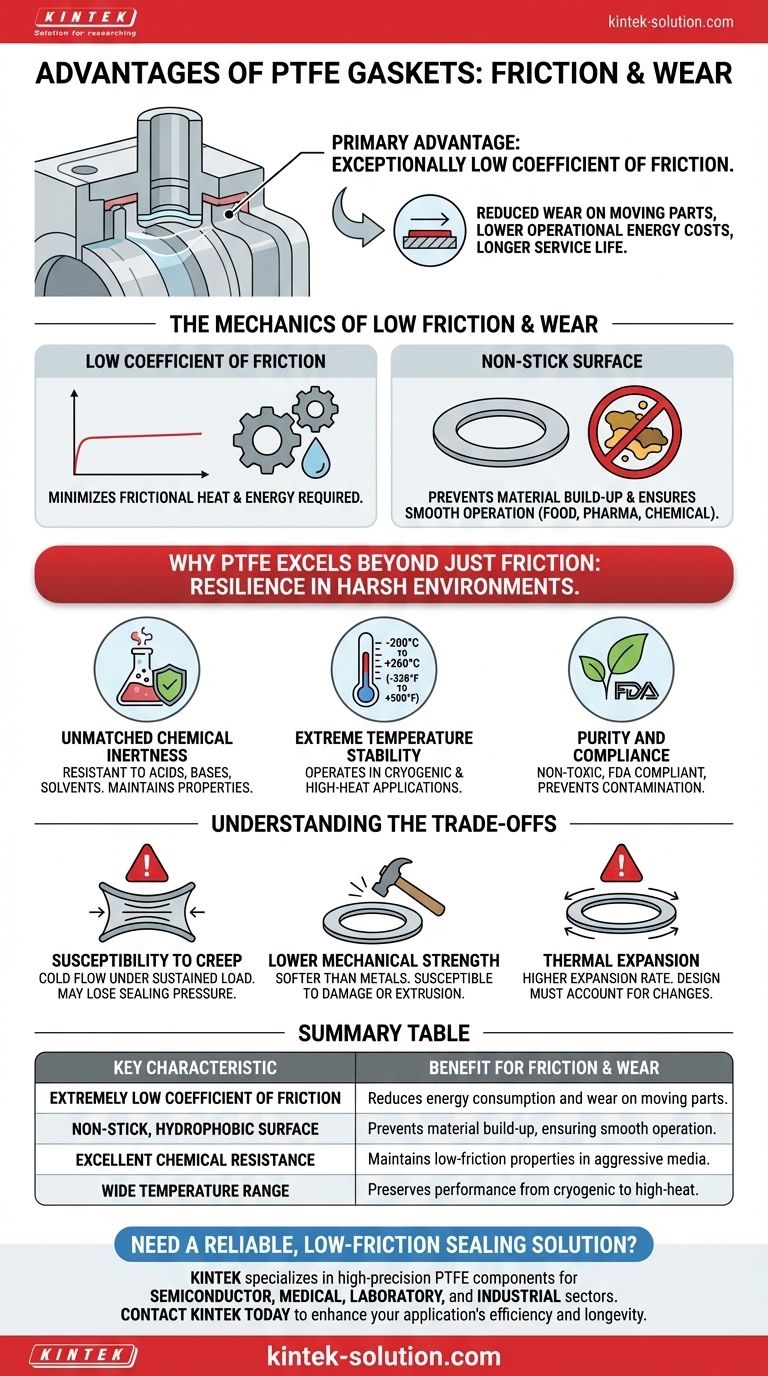

The primary advantage of PTFE gaskets is their exceptionally low coefficient of friction, one of the lowest of any solid material. This inherent slipperiness, combined with a non-stick surface, directly translates to reduced wear on moving parts, lower operational energy costs, and significantly longer service life in demanding applications.

While PTFE is famous for its low friction, its true value emerges from its ability to maintain this property under conditions that would cause most other materials to fail. Its performance in the face of extreme temperatures and corrosive chemicals is what makes it a uniquely reliable sealing solution.

The Mechanics of Low Friction and Wear

To fully appreciate the benefits of Polytetrafluoroethylene (PTFE), we must look beyond the surface-level property and understand its mechanical impact. The advantages are most pronounced in dynamic systems where components are in motion relative to the seal.

Understanding the Coefficient of Friction

A low coefficient of friction means that very little energy is required to move a surface against the PTFE gasket. This property is inherent to PTFE's molecular structure, creating a surface that is exceptionally smooth and non-reactive.

This minimizes the generation of frictional heat, which is a common cause of seal degradation and failure in other materials.

The Impact on Dynamic Seals

In dynamic sealing applications, such as on rotating shafts or reciprocating rods, this low friction is critical. It drastically reduces wear and tear on both the gasket and the machinery itself.

By lowering resistance, PTFE gaskets allow equipment to run more efficiently and smoothly. This extends the operational lifespan of expensive components and reduces the frequency of maintenance and replacement.

The Benefit of a Non-Stick Surface

PTFE's low surface energy results in powerful non-stick, or hydrophobic, properties. This prevents process media, contaminants, or sticky substances from adhering to the gasket surface.

This is vital for maintaining a clean system, preventing material build-up that could impede movement, and ensuring consistent, smooth operation over time, especially in food, pharmaceutical, or chemical processing.

Why PTFE Excels Beyond Just Friction

The low-friction characteristic of PTFE is powerful, but its true utility comes from its resilience in harsh operating environments where other low-friction materials would quickly degrade.

Unmatched Chemical Inertness

PTFE gaskets demonstrate excellent chemical resistance to nearly all acids, bases, and solvents. This means the gasket's physical properties, including its low friction, will not change when exposed to aggressive chemicals.

This makes it an ideal choice for the chemical processing, oil and gas, and pharmaceutical industries, where seal integrity in corrosive environments is paramount.

Extreme Temperature Stability

PTFE maintains its integrity and performance across a remarkably wide temperature range, typically from -200°C to +260°C (-328°F to +500°F).

It does not become brittle at cryogenic temperatures or degrade in high-heat applications within this range, ensuring the seal remains effective and its low-friction benefits are preserved.

Purity and Compliance

Many grades of PTFE are non-toxic and compliant with FDA regulations for food contact. This high purity, combined with its non-stick surface, prevents contamination and makes it a standard material in food, beverage, and medical applications.

Understanding the Trade-offs

No material is perfect. While PTFE offers exceptional performance, its primary limitations stem from its mechanical properties. Being aware of these trade-offs is key to successful implementation.

Susceptibility to Creep

The most significant limitation of pure PTFE is creep, or cold flow. Under sustained compressive load, especially at elevated temperatures, the material can slowly deform, potentially leading to a loss of sealing pressure over time.

Lower Mechanical Strength

Compared to metals or harder plastics, PTFE is a relatively soft material. It can be susceptible to damage from abrasive media or extrusion in high-pressure applications if the gap between sealing surfaces is too large.

Thermal Expansion

PTFE has a higher rate of thermal expansion than most metals. This difference must be accounted for in the design of the sealed joint to ensure a consistent seal is maintained across a range of operating temperatures.

Making the Right Choice for Your Application

Selecting the correct gasket material requires balancing the benefits against the specific demands of your system.

- If your primary focus is dynamic sealing with minimal wear: PTFE is an excellent first choice due to its exceptionally low friction and non-stick surface.

- If your application involves harsh chemicals or extreme temperatures: PTFE's inertness and thermal stability make it one of the most reliable sealing materials available.

- If your application involves high mechanical loads or pressure cycling: Consider a "filled" PTFE, which incorporates materials like glass or carbon to improve creep resistance and mechanical strength.

By understanding both its unique strengths and its inherent limitations, you can leverage PTFE to achieve exceptionally reliable and long-lasting sealing performance.

Summary Table:

| Key Characteristic | Benefit for Friction & Wear |

|---|---|

| Extremely Low Coefficient of Friction | Reduces energy consumption and wear on moving parts. |

| Non-Stick, Hydrophobic Surface | Prevents material build-up, ensuring smooth operation and minimal maintenance. |

| Excellent Chemical Resistance | Maintains low-friction properties even when exposed to aggressive acids, bases, and solvents. |

| Wide Temperature Range (-200°C to +260°C) | Preserves performance and integrity from cryogenic to high-heat applications. |

Need a reliable, low-friction sealing solution for demanding conditions?

At KINTEK, we specialize in manufacturing high-precision PTFE components—including seals, gaskets, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your equipment benefits from PTFE's superior wear resistance and non-stick properties, leading to reduced downtime and lower operational costs.

Whether you need a custom prototype or high-volume production, we deliver components that meet exact specifications for performance in harsh environments.

Contact KINTEK today to discuss how our PTFE solutions can enhance your application's efficiency and longevity.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability