The long-term benefits of Teflon bearings center on operational resilience and a dramatically lower total cost of ownership. Their value is realized over time through an exceptional service life, the elimination of routine maintenance, and consistent performance in environments where traditional bearings would quickly fail. This makes them a strategic investment in reliability rather than just a component purchase.

The core advantage of Teflon bearings is not a single property, but the powerful combination of self-lubrication, chemical inertness, and extreme temperature resistance. This synergy allows them to deliver unparalleled reliability and longevity, drastically reducing maintenance costs and unexpected downtime over the equipment's entire lifecycle.

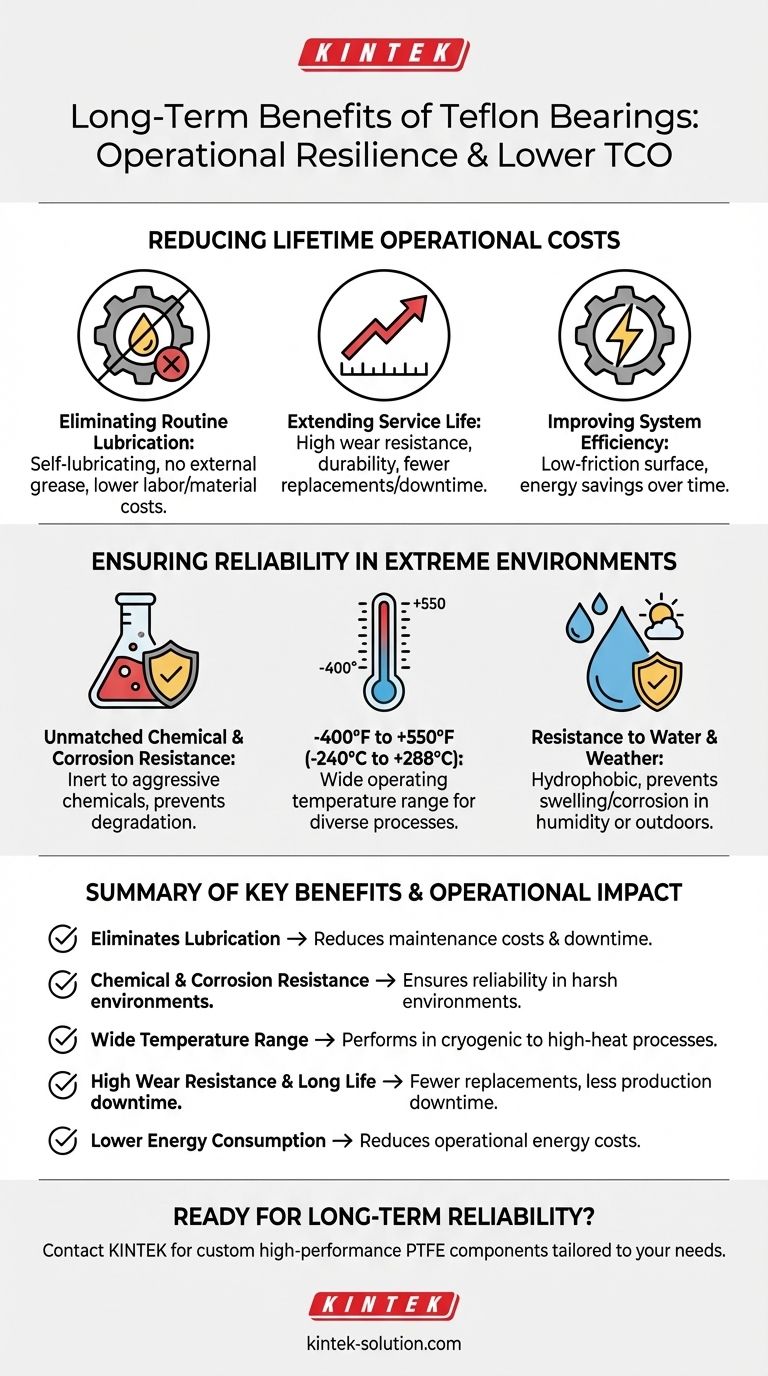

Reducing Lifetime Operational Costs

For most applications, the decision to use a specific bearing comes down to its impact on the bottom line over many years. Teflon (PTFE) excels by targeting the most persistent operational expenses: maintenance, replacement, and energy.

Eliminating Routine Lubrication

Teflon bearings are self-lubricating. Their inherently low coefficient of friction means they do not require external grease or oil to operate smoothly.

This completely eliminates the labor costs, material expenses, and potential equipment downtime associated with periodic lubrication schedules.

Extending Service Life

The material's high wear resistance and immunity to rust and corrosion give it exceptional durability. This directly translates to a longer operational lifespan.

Fewer replacements mean lower component costs and, more importantly, a significant reduction in costly production stoppages for repairs.

Improving System Efficiency

The low-friction surface of Teflon reduces the energy required to overcome resistance within a mechanical system.

While the effect may be small on a micro-level, over years of continuous operation, this can lead to measurable energy savings.

Ensuring Reliability in Extreme Environments

Many long-term failures are caused by environmental factors that degrade standard bearing materials. Teflon is engineered to withstand these harsh conditions, ensuring predictable performance.

Unmatched Chemical and Corrosion Resistance

Teflon is one of the most chemically inert substances known. It is highly resistant to a vast range of aggressive chemicals, solvents, and acids.

This prevents the material degradation and eventual failure that plagues metal bearings in corrosive settings. This property is so effective that Teflon is often used to encapsulate and protect other materials, like the elastomeric cores in o-rings.

Wide Operating Temperature Range

These bearings perform reliably across an exceptionally wide thermal spectrum, typically from -400°F to +550°F (-240°C to +288°C).

This makes them suitable for everything from cryogenic applications to high-temperature industrial processes, where conventional lubricants would either freeze or burn off.

Resistance to Water and Weather

Teflon is hydrophobic, meaning it repels water and is unaffected by moisture. This prevents swelling, degradation, and corrosion in high-humidity or outdoor applications.

Understanding the Trade-offs

No material is perfect for every application. An objective assessment requires understanding the limitations of Teflon bearings.

Lower Load Capacity

Compared to steel or bronze bearings, Teflon is a softer material. It can be susceptible to "creep" or deformation under very high, sustained static loads.

For high-load applications, reinforced or composite Teflon bearings are often necessary to provide the required structural strength.

Higher Thermal Expansion

Teflon expands and contracts with temperature changes more than most metals.

Engineers must account for this higher coefficient of thermal expansion in their designs to ensure proper clearances are maintained throughout the operating temperature range.

Higher Initial Cost

The upfront purchase price of a Teflon bearing may be higher than that of a simple bronze bushing or rolling-element bearing.

This initial cost must be weighed against the significant long-term savings from eliminated maintenance and extended service life to calculate the true total cost of ownership.

Making the Right Choice for Your Application

Selecting the correct bearing material is about aligning its properties with your primary operational goals.

- If your primary focus is minimizing maintenance and downtime: The self-lubricating and highly durable nature of Teflon bearings makes them an ideal choice.

- If your primary focus is reliability in harsh environments: Teflon's unmatched chemical and temperature resistance provides performance where most other materials would fail.

- If your primary focus is supporting high structural loads: A standard Teflon bearing may not be sufficient; you should evaluate composite or reinforced PTFE bearings designed for greater strength.

Ultimately, choosing Teflon bearings is an investment in long-term operational stability and predictability.

Summary Table:

| Key Long-Term Benefit | Impact on Operations |

|---|---|

| Eliminates Routine Lubrication | Reduces labor, material costs, and downtime from maintenance schedules. |

| Exceptional Chemical & Corrosion Resistance | Prevents failure in harsh environments, ensuring reliability. |

| Wide Temperature Range (-400°F to +550°F) | Performs reliably in cryogenic to high-heat processes. |

| High Wear Resistance & Long Service Life | Fewer replacements and less production downtime. |

| Lower System Energy Consumption | Reduces operational energy costs over time. |

Ready to invest in long-term reliability and reduce your total cost of ownership?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including custom bearings, seals, and labware for the semiconductor, medical, laboratory, and industrial sectors. Our precision production and custom fabrication services—from prototypes to high-volume orders—ensure you get a bearing solution perfectly tailored to your operational needs and harsh environment challenges.

Contact KINTEB today to discuss how our Teflon bearings can enhance your equipment's lifespan and operational efficiency.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are the key roles of PTFE rotary shaft seals in industrial applications? Ensure Reliability in Extreme Conditions

- Are PTFE rotary shaft seals suitable for food processing applications? Ensure Superior Hygiene and Performance

- What role does the PTFE lining play in these valves? Achieve Superior Chemical Resistance and Purity

- What are PTFE expansion joints and what are their primary functions? Protect Your Piping System from Movement and Corrosion

- What are the key properties of virgin PTFE? Unlock Extreme Chemical & Thermal Resistance

- What is the temperature tolerance range of PTFE compensators? Ideal for Extreme Heat and Cryogenic Systems

- What are the two common application methods for PTFE in slide bearings? A Guide to Linear and Rotational Movement

- What types of fluids are PTFE-lined pipes suitable for transporting? Handle Nearly Any Fluid with Confidence