At its core, a PTFE-lined pipe is suitable for transporting nearly any fluid you can imagine. Its remarkable utility comes from being one of the most chemically inert materials used in industrial applications, making it a default choice for caustic, acidic, hazardous, corrosive, and high-purity liquids.

The central takeaway is that PTFE's value is not in a limited list of compatible fluids, but in its near-universal resistance to chemical attack. The primary question is rarely "Can PTFE handle this fluid?" but rather, "Does my application's temperature and pressure fall within the operational limits of the lined pipe system?"

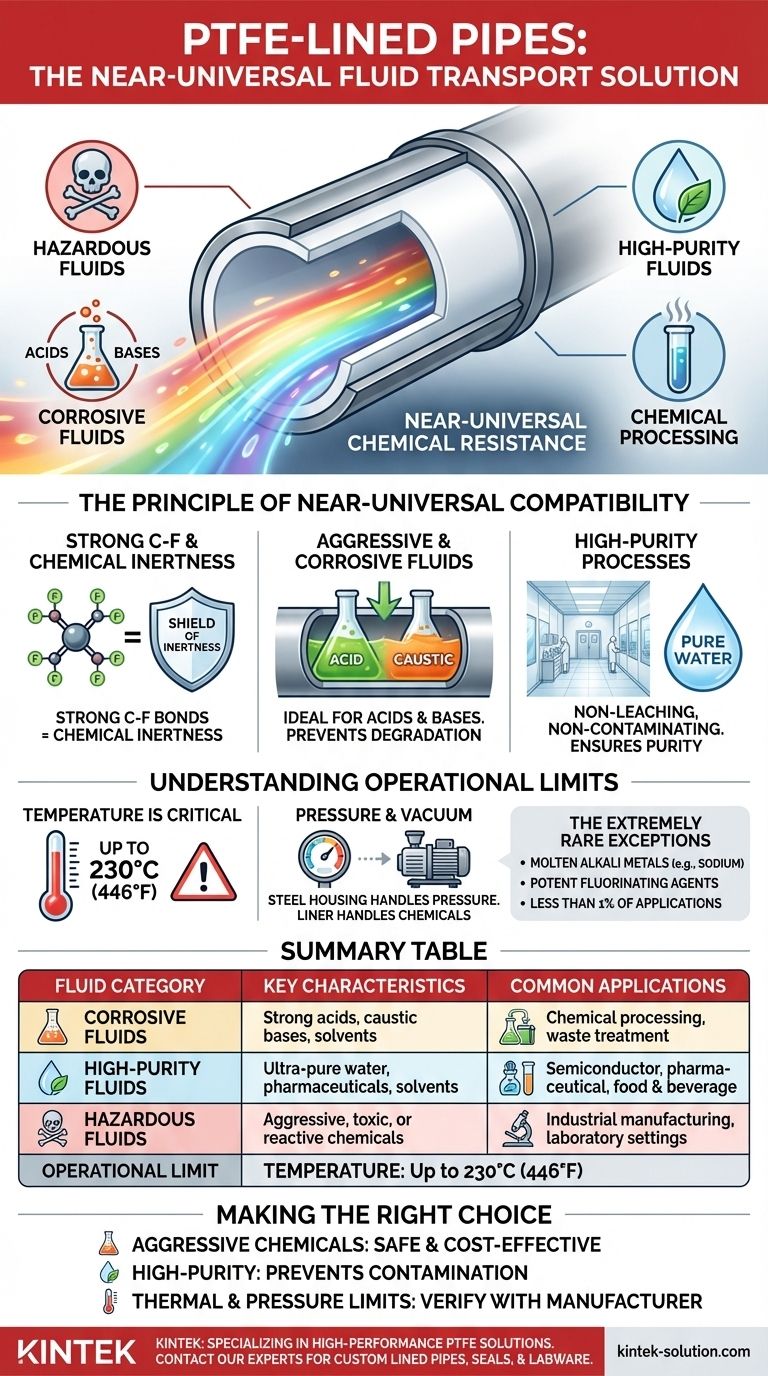

The Principle of Near-Universal Compatibility

The effectiveness of PTFE-lined pipe stems from the unique molecular structure of Polytetrafluoroethylene (PTFE). Understanding this principle is key to knowing why it is so widely trusted for critical applications.

What Makes PTFE So Resistant?

PTFE is a fluoropolymer, characterized by incredibly strong carbon-fluorine bonds. This stable, non-reactive molecular structure is the source of its signature chemical inertness.

This structure effectively creates a barrier that is unaffected by the vast majority of industrial chemicals, preventing the pipe itself from degrading.

Handling Aggressive and Corrosive Fluids

This chemical inertness makes PTFE-lined pipes the ideal solution for transporting highly corrosive fluids.

This category includes aggressive substances like strong acids, caustic bases (alkalis), and other hazardous chemicals that would quickly destroy most metal or plastic piping systems.

Ensuring High-Purity Processes

In industries like pharmaceuticals or semiconductor manufacturing, preventing contamination is paramount. PTFE is essential for these high-purity applications.

Because the material is so non-reactive, it does not leach particles or chemicals into the fluid it carries. This ensures the purity and integrity of the final product.

Understanding the Operational Limits

While chemically robust, PTFE-lined pipe is a composite system. Its performance is governed not just by the liner, but also by the supporting steel housing and the operational environment.

The Critical Role of Temperature

The single most important limiting factor for PTFE is temperature. While it offers excellent performance, it has a distinct operational ceiling.

Most PTFE-lined systems are rated for continuous service at temperatures up to 230°C (446°F). Exceeding this can compromise the structural integrity of the liner, even if the chemical resistance remains.

Pressure and Vacuum Considerations

The steel housing of the pipe is designed to handle the internal pressure. The PTFE liner's job is to contain the fluid chemically.

It is crucial that the liner is manufactured and installed correctly to handle the rated pressure at a given temperature without risk of cracking or collapsing, especially under vacuum conditions.

The Extremely Rare Exceptions

For all practical purposes, PTFE is universally resistant. However, a few substances are known to attack it under specific conditions.

These exceptions are limited to exotic materials like molten alkali metals (e.g., sodium) and some potent fluorinating agents. For over 99% of industrial applications, these exceptions are not a concern.

Making the Right Choice for Your Application

Selecting the correct piping system requires matching the material's properties to your primary operational goal.

- If your primary focus is aggressive chemical transport: PTFE-lined pipe is one of the safest and most cost-effective long-term solutions due to its near-universal chemical inertness.

- If your primary focus is high-purity processes: The non-leaching and non-contaminating surface of a PTFE liner makes it the ideal choice for maintaining fluid integrity.

- If you are operating near thermal or pressure limits: You must verify that your specific conditions fall within the manufacturer's rated specifications for the entire lined pipe assembly.

By understanding that PTFE's strength is its chemical non-reactivity, you can confidently specify it for nearly any fluid transfer challenge within its physical limits.

Summary Table:

| Fluid Category | Key Characteristics | Common Applications |

|---|---|---|

| Corrosive Fluids | Strong acids, caustic bases, solvents | Chemical processing, waste treatment |

| High-Purity Fluids | Ultra-pure water, pharmaceuticals, solvents | Semiconductor, pharmaceutical, food & beverage |

| Hazardous Fluids | Aggressive, toxic, or reactive chemicals | Industrial manufacturing, laboratory settings |

| Operational Limit | Temperature: Up to 230°C (446°F) | Ensure system specifications match application requirements |

Need a reliable fluid handling solution for aggressive or high-purity applications?

KINTEK specializes in manufacturing high-performance PTFE components, including custom-lined pipes, seals, and labware. We serve the semiconductor, medical, laboratory, and industrial sectors, ensuring precision and chemical integrity from prototype to high-volume production.

Let us help you design a system that meets your exact chemical and operational demands. Contact our experts today to discuss your specific requirements and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- Which ball valve seat material is best for high-temperature applications? PEEK Offers Superior Thermal Stability

- What industries benefit from using PTFE gaskets in ball valves? Ensure Purity & Reliability in Critical Processes

- What are the advantages and disadvantages of etched PTFE diaphragms? Solve Critical Delamination Failures

- What are the key features of PTFE V-Rings? Master Sealing in Extreme Environments

- How do PTFE extruded rods contribute to electrical insulation? Ensure Uncompromising Performance in Harsh Environments

- How do expanded PTFE (ePTFE) gaskets differ from other types? Solve Cold Flow & Seal Imperfect Flanges

- Which industries commonly use Teflon bushes? Solve Critical Engineering Challenges in Harsh Environments

- How does thickness affect PTFE sheet selection? A Guide to Balancing Strength and Flexibility