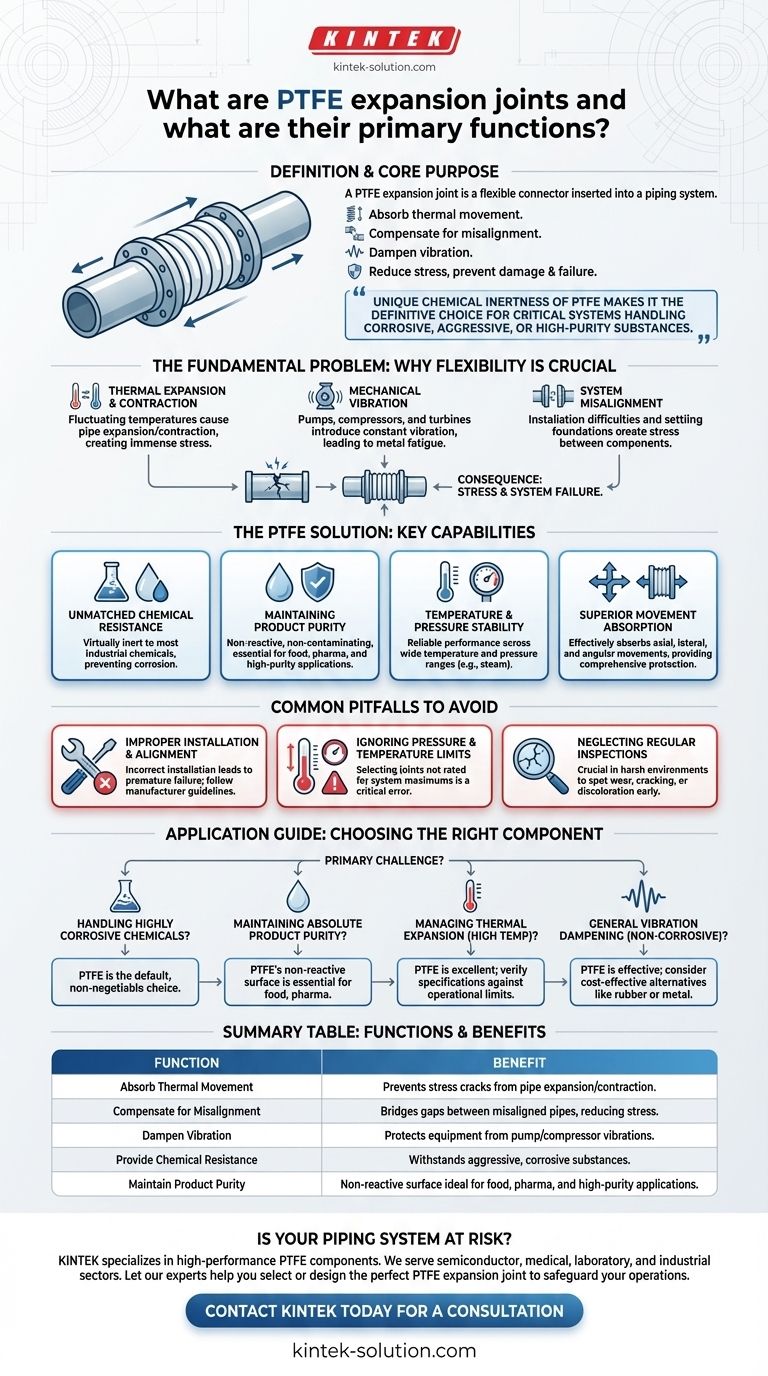

At its core, a PTFE expansion joint is a specialized, flexible connector designed to be inserted into a piping system. Its primary functions are to absorb movement caused by thermal changes, compensate for pipe misalignment, dampen vibration, and ultimately reduce stress on the entire system to prevent damage and failure.

The essential role of any expansion joint is to manage movement, but the unique chemical inertness of Polytetrafluoroethylene (PTFE) makes it the definitive choice for protecting critical systems that handle corrosive, aggressive, or high-purity substances.

The Fundamental Problem: Why Piping Systems Need Flexibility

Industrial piping is rarely a static environment. Several forces are constantly at work that can compromise the integrity of rigid pipes, flanges, and connected equipment.

Thermal Expansion and Contraction

As process temperatures fluctuate, pipe materials expand when heated and contract when cooled. Over long runs, this movement can generate immense stress, leading to cracks or damaged supports.

Mechanical Vibration

Equipment like pumps, compressors, and turbines introduce constant vibration into a piping system. Left unmanaged, this energy can cause metal fatigue and loosen connections over time.

System Misalignment

Perfect alignment during installation is difficult to achieve and can shift as foundations settle. An expansion joint provides a flexible bridge, preventing stress from building up between misaligned components.

The Consequence: Stress and System Failure

These forces—thermal, vibrational, and mechanical—all result in stress. A PTFE expansion joint acts as an engineered point of absorption, isolating these forces and protecting more expensive or critical parts of the system from leaks and catastrophic failure.

The PTFE Solution: Key Capabilities

While various materials can be used for expansion joints, PTFE offers a unique combination of properties that make it indispensable in demanding industries.

Unmatched Chemical Resistance

PTFE is virtually inert to almost all industrial chemicals. This makes it essential in chemical processing plants where it prevents corrosion that would quickly destroy metal or rubber alternatives.

Maintaining Product Purity

Because PTFE is non-reactive and non-contaminating, it is a critical component in pharmaceutical, food, and beverage manufacturing. It ensures that the substance being transported remains pure and unaltered.

Temperature and Pressure Stability

PTFE expansion joints are engineered to perform reliably across a wide range of temperatures and pressures, making them suitable for environments like power plants that handle high-pressure steam and fluctuating conditions.

Superior Movement Absorption

The inherent flexibility of PTFE bellows allows them to effectively absorb axial (compression, extension), lateral (offset), and angular movements, providing comprehensive protection for the piping system.

Common Pitfalls to Avoid

To function correctly, a PTFE expansion joint relies on proper application and maintenance. Missteps can easily negate its benefits.

Improper Installation and Alignment

The most common point of failure is incorrect installation. If the adjacent pipes are not properly aligned and supported, the expansion joint can be subjected to stresses it was not designed to handle, leading to premature failure. Always follow manufacturer guidelines precisely.

Ignoring Pressure and Temperature Limits

While robust, PTFE has operational limits. Selecting a joint that is not rated for the system's maximum pressure or temperature is a critical error. This is especially important in high-pressure steam or volatile chemical applications.

Neglecting Regular Inspections

In harsh industrial environments, regular visual inspections are crucial. Look for any signs of wear, cracking, or discoloration on the bellows, as these can be early indicators that a replacement is needed before a leak occurs.

How to Apply This to Your Project

Choosing the right component depends entirely on the primary challenge you need to solve within your system.

- If your primary focus is handling highly corrosive chemicals: PTFE is the default, non-negotiable choice for ensuring the long-term integrity of your system.

- If your primary focus is maintaining absolute product purity: The non-reactive surface of PTFE is essential for applications in food, beverage, and pharmaceutical processing.

- If your primary focus is managing thermal expansion in a high-temperature system: A PTFE joint is an excellent solution, provided you verify its specifications against your system's maximum operational limits.

- If your primary focus is general vibration dampening in a non-corrosive system: While PTFE is effective, you may also consider other materials like rubber or metal, which could be more cost-effective for simpler applications.

Ultimately, selecting the right expansion joint is about proactively safeguarding your entire system against the inevitable forces of movement and chemical attack.

Summary Table:

| Function | Benefit |

|---|---|

| Absorb Thermal Movement | Prevents stress cracks from pipe expansion/contraction |

| Compensate for Misalignment | Bridges gaps between misaligned pipes, reducing stress |

| Dampen Vibration | Protects equipment from pump/compressor vibrations |

| Provide Chemical Resistance | Withstands aggressive, corrosive substances |

| Maintain Product Purity | Non-reactive surface ideal for food, pharma, and high-purity applications |

Is your piping system at risk from thermal stress, vibration, or corrosive chemicals?

KINTEK specializes in manufacturing high-performance, precision PTFE components—including custom expansion joints, seals, liners, and labware. We serve the semiconductor, medical, laboratory, and industrial sectors, delivering solutions from prototypes to high-volume orders.

Our PTFE expansion joints are engineered to protect your critical systems, ensuring longevity and reliability. Let our experts help you select or design the perfect component for your specific needs.

Contact KINTEK today for a consultation and safeguard your operations.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability