At its core, virgin Polytetrafluoroethylene (PTFE) is defined by a unique combination of extreme resistances. It is almost completely inert to nearly all chemicals, possesses one of the lowest coefficients of friction of any known solid, and maintains its stability across a vast temperature range from -200°C to +260°C (-328°F to +500°F).

Virgin PTFE's value lies not in a single property, but in its rare synthesis of chemical, thermal, and electrical stability. However, understanding its key mechanical limitation—its tendency to "creep" under pressure—is absolutely critical for successful application.

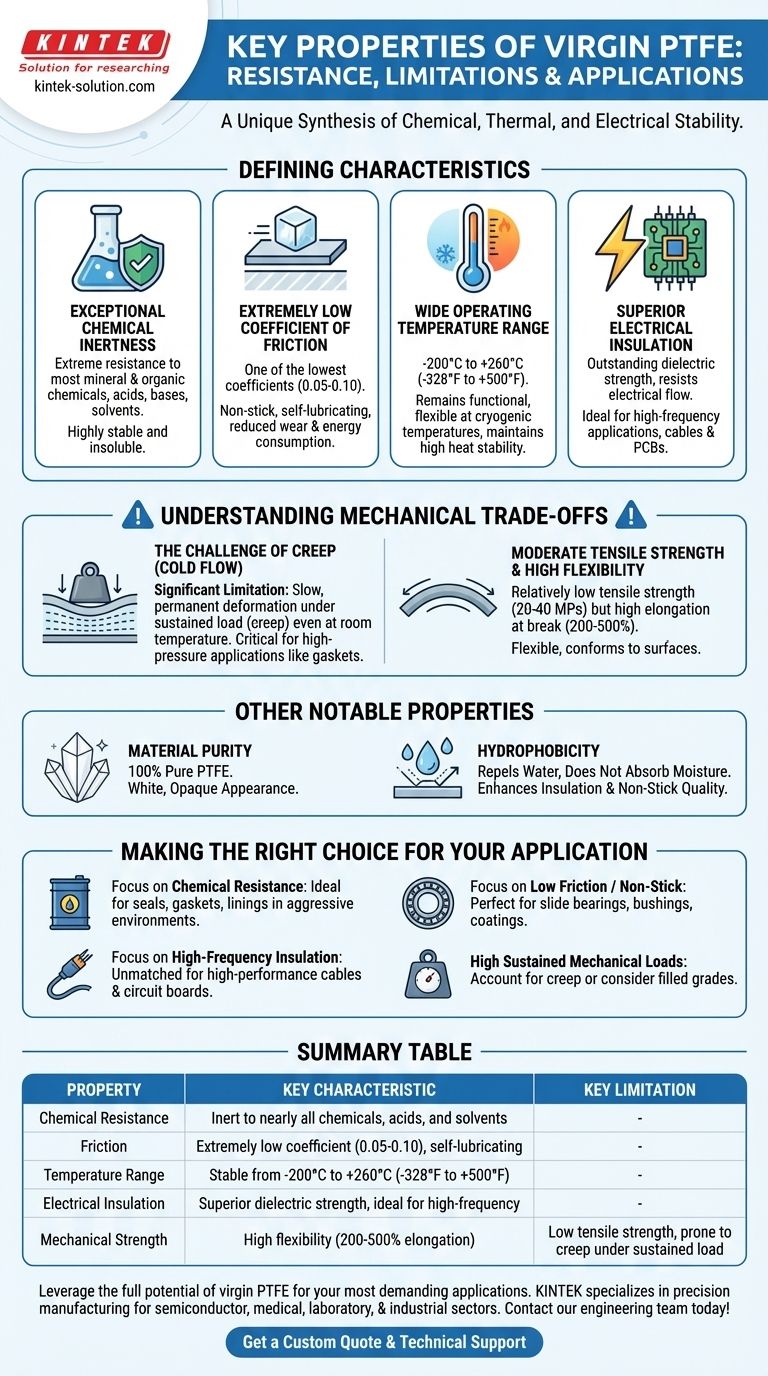

The Defining Characteristics of Virgin PTFE

To select the right material, you must understand how its core properties translate to real-world performance. Virgin PTFE, which is 100% pure with no added fillers, excels in several distinct areas.

Exceptional Chemical Inertness

Virgin PTFE offers extreme resistance to most mineral and organic chemicals. This includes aggressive acids, bases, and solvents that would degrade lesser polymers.

Its molecular structure is incredibly stable, making it highly insoluble. This is why it is a primary choice for components used in pharmaceutical, chemical processing, and food and beverage applications.

Extremely Low Coefficient of Friction

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice (a value between 0.05 and 0.10).

This results in its signature non-stick and self-lubricating surface. Parts made from PTFE move with minimal resistance, reducing wear and energy consumption in mechanical systems.

Wide Operating Temperature Range

This material demonstrates remarkable thermal stability. It remains functional and does not degrade in continuous service at temperatures as high as 260°C (500°F).

Crucially, it also maintains high flexural strength and does not become brittle at cryogenic temperatures as low as -200°C (-328°F), a range where many other plastics fail.

Superior Electrical Insulation

Virgin PTFE is an outstanding electrical insulator with high dielectric strength. It resists the flow of electricity exceptionally well.

This property is especially valuable at high radio frequencies, making it a critical material for insulators in high-performance coaxial cables and printed circuit boards (PCBs).

Understanding the Mechanical Trade-offs

While its resistance properties are extreme, virgin PTFE's mechanical characteristics are more moderate. Ignoring these trade-offs is a common source of failure in engineering design.

The Challenge of Creep (Cold Flow)

This is the most significant mechanical limitation of virgin PTFE. Creep, or cold flow, is the material's tendency to slowly and permanently deform when subjected to a sustained load, even at room temperature.

For applications involving constant high pressure, such as high-load gaskets or structural components, this deformation must be accounted for in the design. In many cases, a "filled" grade of PTFE (with additives like glass or carbon) is used to improve creep resistance.

Moderate Tensile Strength

Compared to its other extreme properties, virgin PTFE has a relatively low tensile strength, typically ranging from 20-40 MPa (2900-5800 psi).

It is not intended for applications requiring high structural rigidity or load-bearing capacity on its own.

High Flexibility

Counterbalancing its moderate strength is its high flexibility. Virgin PTFE has a very high elongation at break (200-500%), meaning it can bend and flex significantly before failing.

This flexibility is advantageous for components like seals, tubing, and liners that must conform to surfaces or endure movement.

Other Notable Properties

A few other physical traits round out the profile of this unique material.

Material Purity and Appearance

As a "virgin" grade, it is 100% pure polytetrafluoroethylene. It has a distinct white, opaque appearance.

Hydrophobicity

PTFE is hydrophobic, meaning it actively repels water and does not absorb moisture. This contributes to its excellent performance as an electrical insulator and its non-stick quality.

Making the Right Choice for Your Application

Selecting virgin PTFE requires aligning its unique strengths with your primary engineering goal.

- If your primary focus is chemical resistance: Virgin PTFE is an ideal choice for seals, gaskets, and linings in aggressive chemical environments.

- If your primary focus is low friction or a non-stick surface: Its self-lubricating nature makes it perfect for slide bearings, bushings, and coatings where external lubrication is difficult.

- If your primary focus is high-frequency electrical insulation: Its excellent dielectric properties are unmatched for insulators in high-performance cables and circuit boards.

- If your application involves high, sustained mechanical loads: You must account for its tendency to creep or consider using a filled grade of PTFE for improved mechanical strength.

By balancing its remarkable resistances against its mechanical limits, you can effectively leverage virgin PTFE in the most demanding applications.

Summary Table:

| Property | Key Characteristic | Key Limitation |

|---|---|---|

| Chemical Resistance | Inert to nearly all chemicals, acids, and solvents | - |

| Friction | Extremely low coefficient (0.05-0.10), self-lubricating | - |

| Temperature Range | Stable from -200°C to +260°C (-328°F to +500°F) | - |

| Electrical Insulation | Superior dielectric strength, ideal for high-frequency applications | - |

| Mechanical Strength | High flexibility (200-500% elongation) | Low tensile strength, prone to creep under sustained load |

Leverage the full potential of virgin PTFE for your most demanding applications.

At KINTEK, we specialize in the precision manufacturing of high-performance PTFE components—including custom seals, liners, labware, and more—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your designs perfectly balance PTFE's exceptional resistances with its mechanical characteristics.

Contact our engineering team today to discuss your project requirements, from prototypes to high-volume production. Let us help you create the ideal solution.

Get a Custom Quote & Technical Support

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech