In essence, PTFE rotary shaft seals serve two primary, critical roles in industrial machinery: they prevent the leakage of internal fluids like lubricants and they block external contaminants such as dust, dirt, and moisture from entering the system. Their unique material properties allow them to perform these functions reliably in extreme operating conditions where conventional seals would quickly fail.

The fundamental value of a PTFE rotary shaft seal isn't just that it seals; it's that it maintains seal integrity under conditions of high speed, extreme temperature, and chemical aggression that would destroy traditional elastomeric seals.

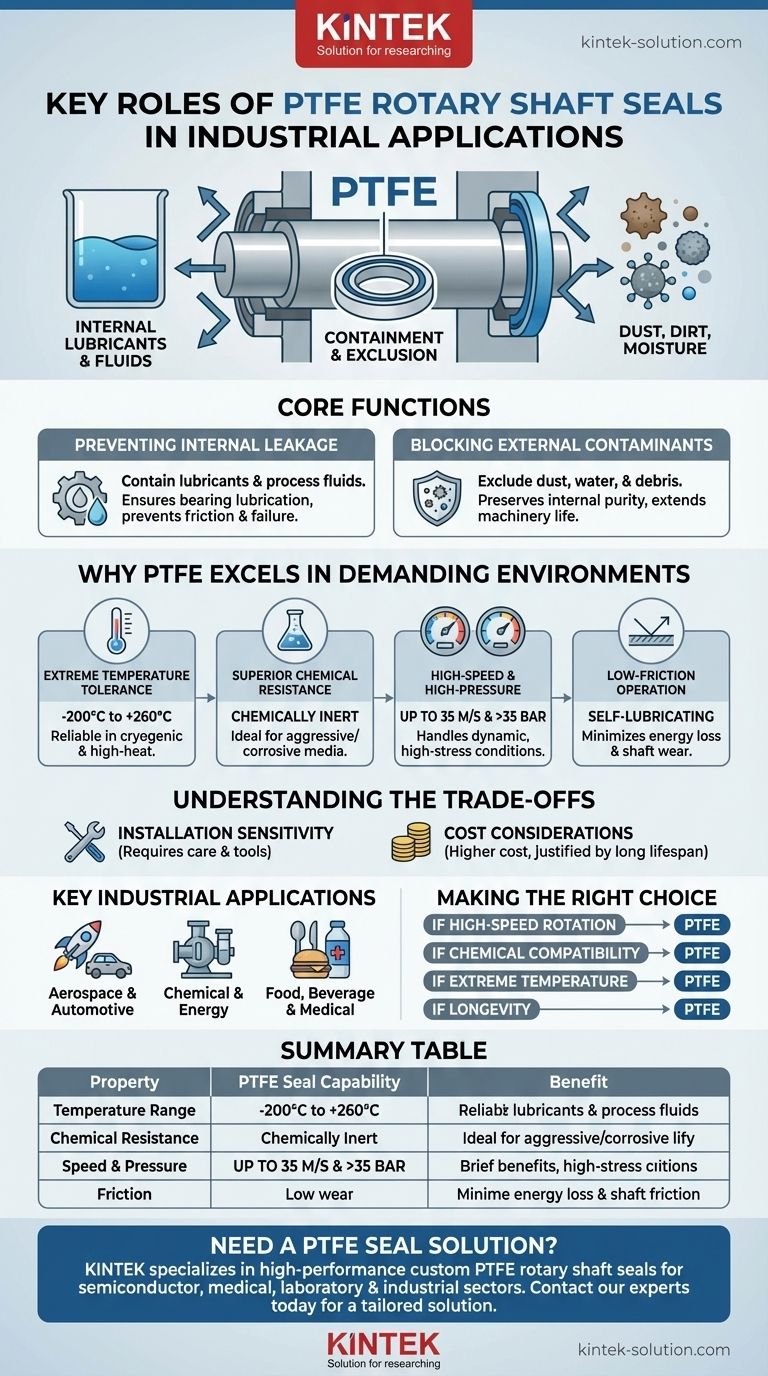

The Core Functions: Containment and Exclusion

At its most basic level, a rotary shaft seal is a barrier. PTFE seals are engineered to create a highly effective and durable barrier on rotating equipment.

Preventing Internal Leakage (Containment)

A primary role of these seals is to contain lubricants and other process fluids within the machinery.

This ensures that bearings and other critical components remain properly lubricated, preventing friction, wear, and premature equipment failure.

Blocking External Contaminants (Exclusion)

Equally important is the seal's function to exclude contaminants from the outside environment.

Dust, water, and process debris can cause severe abrasive damage to internal components. The seal acts as a crucial line of defense, preserving the purity of the internal environment and extending the machinery's operational life.

Why PTFE Excels in Demanding Environments

The choice of Polytetrafluoroethylene (PTFE) is not arbitrary. Its material characteristics make it uniquely suited for the most challenging industrial applications.

Extreme Temperature Tolerance

PTFE seals can operate across an exceptionally wide temperature range, typically from -200°C to +260°C (-328°F to +500°F).

This allows them to function reliably in cryogenic applications as well as in high-heat environments like engines and compressors, where other materials would become brittle or degrade.

Superior Chemical Resistance

PTFE is chemically inert to almost all industrial chemicals and fluids.

This makes it the ideal choice for equipment in chemical processing, pharmaceuticals, and oil and gas, where seals are exposed to aggressive or corrosive media that would dissolve or swell other materials.

High-Speed and High-Pressure Capability

These seals are engineered for dynamic, high-stress conditions. They can handle shaft surface speeds up to 35 m/s and pressures exceeding 35 BAR.

Their low-friction nature prevents the buildup of destructive heat at high rotational speeds, a common failure point for traditional seals.

Low-Friction Operation

PTFE has one of the lowest coefficients of friction of any solid material. This self-lubricating property minimizes energy loss and wear on the rotating shaft.

This non-stick characteristic also reduces maintenance requirements, as it prevents the seal from adhering to the shaft during periods of downtime.

Understanding the Trade-offs

While highly effective, PTFE seals are a specialized solution with specific considerations. They are not a universal replacement for all seal types.

Installation Sensitivity

Compared to more flexible elastomeric seals, PTFE can be more rigid. This often requires more care and specialized tools during installation to avoid damaging the seal lip.

Cost Considerations

Due to the advanced material and manufacturing processes, PTFE seals are typically a higher-cost component compared to standard nitrile or viton seals.

This cost is justified by their significantly longer lifespan and reliability in applications where the cost of failure (downtime, repairs, and safety risks) is extremely high.

Key Industrial Applications

The unique properties of PTFE seals have made them indispensable across a wide range of critical industries.

Aerospace and Automotive

In aerospace and motorsports, seals must perform under extreme temperature fluctuations and high speeds. PTFE's reliability and low outgassing properties are essential for engines, actuators, and landing gear.

Chemical and Energy Sectors

For pumps, compressors, and mixers in the oil & gas and chemical processing industries, PTFE seals provide the necessary resistance to corrosive fluids and high pressures, preventing dangerous leaks.

Food, Beverage, and Medical

The non-reactive and hygienic properties of PTFE make it ideal for food processing, dairy, and medical equipment. These seals do not contaminate the product and can withstand aggressive clean-in-place (CIP) procedures.

Making the Right Choice for Your Goal

Selecting a seal is about matching the material's capabilities to the operational demands of your application.

- If your primary focus is high-speed rotation: PTFE is the superior choice due to its low friction and ability to dissipate heat, preventing premature wear and failure.

- If your primary focus is chemical compatibility: PTFE's inertness provides unmatched reliability when sealing against aggressive chemicals, solvents, or process fluids.

- If your primary focus is extreme temperature ranges: PTFE is one of the few materials that can maintain seal integrity in both cryogenic and high-heat conditions.

- If your primary focus is longevity and reduced maintenance: The durability and low-wear characteristics of PTFE seals lead to a longer service life and less downtime in critical equipment.

Ultimately, specifying a PTFE rotary shaft seal is an engineering decision to ensure operational reliability where standard solutions are guaranteed to fail.

Summary Table:

| Property | PTFE Seal Capability | Benefit |

|---|---|---|

| Temperature Range | -200°C to +260°C (-328°F to +500°F) | Reliability in cryogenic to high-heat applications |

| Chemical Resistance | Inert to almost all industrial chemicals | Ideal for aggressive/corrosive media |

| Speed & Pressure | Up to 35 m/s & exceeding 35 BAR | Superior performance in high-stress, dynamic conditions |

| Friction | Extremely low coefficient of friction | Self-lubricating, reduces energy loss and shaft wear |

Need a PTFE seal solution for your demanding application?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including custom rotary shaft seals, for the semiconductor, medical, laboratory, and industrial sectors. Our precision production and custom fabrication services—from prototypes to high-volume orders—ensure you get a seal that delivers unmatched reliability, extends equipment life, and minimizes downtime in extreme conditions.

Contact our experts today to discuss your specific requirements and get a solution tailored for your success.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems