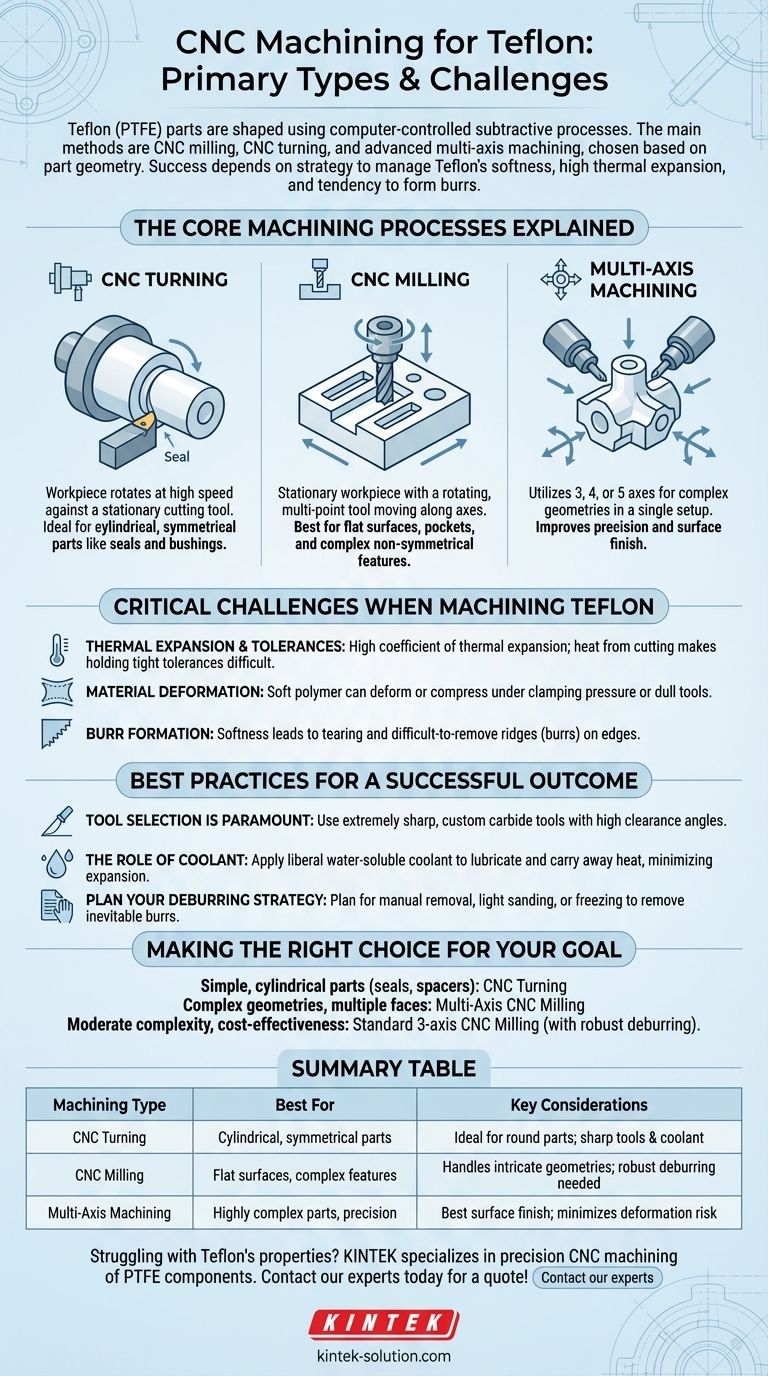

The primary methods for CNC machining Teflon are CNC milling, CNC turning, and advanced multi-axis machining. These subtractive processes use computer-controlled tools to precisely remove material from a solid block of Teflon (PTFE), shaping it into a final part. The choice between them depends entirely on the part's geometry and complexity.

While the machining processes are standard, success with Teflon is not about the machine itself, but about the strategy. Its unique properties—softness, high thermal expansion, and tendency to form burrs—demand specific techniques, sharp tooling, and careful heat management.

The Core Machining Processes Explained

Understanding the fundamental processes is the first step. Each method manipulates either the tool or the workpiece to achieve the desired shape.

CNC Turning

In CNC turning, the block of Teflon material is mounted on a chuck and rotates at high speed. A stationary cutting tool is then moved along the rotating workpiece to remove material.

This method is ideal for creating cylindrical, conical, or other symmetrical, round parts like seals, bushings, and insulators.

CNC Milling

With CNC milling, the Teflon workpiece remains stationary while a multi-point cutting tool rotates and moves along multiple axes. The machine's computer guides the tool to cut slots, holes, and complex surface contours.

Milling is the go-to process for creating parts with flat surfaces, pockets, and intricate non-symmetrical features.

Multi-Axis Machining

Multi-axis machining is an advanced form of milling or turning that utilizes 3, 4, or 5 axes of movement simultaneously. This allows the cutting tool to approach the workpiece from virtually any angle.

For Teflon, 5-axis machines are particularly valuable. They can produce highly complex geometries in a single setup, which improves precision, creates a better surface finish, and reduces the risk of deformation from repeated clamping.

Critical Challenges When Machining Teflon

Teflon is not a forgiving material like aluminum or steel. Its properties present unique challenges that must be anticipated and managed to avoid scrapped parts.

Thermal Expansion and Tolerances

Teflon has a very high coefficient of thermal expansion. The heat generated during cutting can cause the material to expand significantly, making it extremely difficult to hold tight tolerances.

Material Deformation

As a soft polymer, Teflon can easily deform or compress under the pressure of machine clamps or even a dull cutting tool. This can lead to dimensional inaccuracies in the finished part.

Burr Formation

One of the most common issues is the formation of burrs, which are thin ridges of unwanted material left on the part's edges. Teflon's softness makes it prone to tearing rather than clean shearing, resulting in burrs that are difficult to remove.

Best Practices for a Successful Outcome

Overcoming Teflon's challenges requires a specific approach that prioritizes finesse over force.

Tool Selection is Paramount

The single most important factor is using extremely sharp cutting tools. Custom carbide tools with high clearance angles are often recommended to ensure a clean shearing action and prevent material from rubbing or melting.

The Role of Coolant

Applying a liberal amount of water-soluble coolant is essential. The coolant serves two purposes: it lubricates the cut to reduce friction and, more importantly, it carries away heat to minimize thermal expansion.

Plan Your Deburring Strategy

Deburring should not be an afterthought. Because burrs are almost inevitable, you must plan how to remove them. Common techniques include manual removal with a sharp blade, light sanding, or even freezing the part to make the burrs brittle and easier to snap off.

Making the Right Choice for Your Goal

Select your machining process based on the specific requirements of your component.

- If your primary focus is simple, cylindrical parts like seals or spacers: CNC turning is the most direct and efficient method.

- If your primary focus is complex geometries with features on multiple faces: Multi-axis CNC milling is necessary to achieve high precision and a superior surface finish.

- If your primary focus is cost-effectiveness on parts with moderate complexity: Standard 3-axis CNC milling is a capable choice, but be prepared for a robust deburring process.

Ultimately, mastering Teflon machining comes from respecting the material's unique behavior and adapting your process accordingly.

Summary Table:

| Machining Type | Best For | Key Considerations |

|---|---|---|

| CNC Turning | Cylindrical, symmetrical parts (seals, bushings) | Ideal for round parts; requires sharp tools & coolant |

| CNC Milling | Flat surfaces, pockets, complex non-symmetrical features | Handles intricate geometries; robust deburring needed |

| Multi-Axis Machining | Highly complex parts requiring single-setup precision | Best surface finish; minimizes deformation risk |

Struggling with Teflon's softness, thermal expansion, or burrs? KINTEK specializes in precision CNC machining of PTFE components for semiconductor, medical, laboratory, and industrial applications. Our expertise in custom tooling, heat management, and deburring ensures your parts meet exact specifications—from prototypes to high-volume orders. Contact our experts today to discuss your project and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments