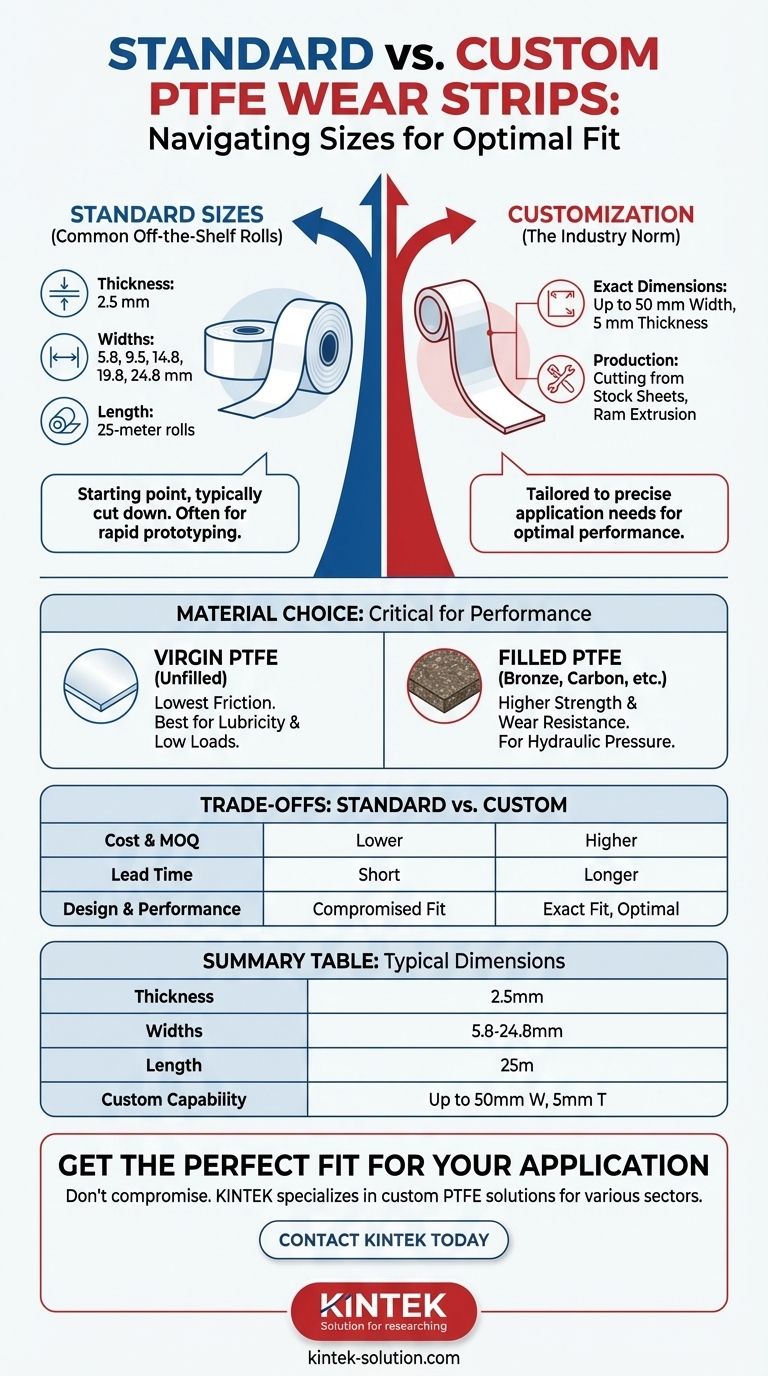

In short, standard PTFE wear strips are most commonly available in a thickness of 2.5 mm and widths of 5.8, 9.5, 14.8, 19.8, and 24.8 mm. These are typically supplied in long rolls, often 25 meters in length, intended to be cut down for specific applications. However, the true standard in this field is customization, as most applications require precise dimensions that may fall outside these common off-the-shelf sizes.

While a handful of "standard" roll sizes exist for convenience, the industry operates on the principle of customization. The critical takeaway is that you should design for your application's specific needs, as suppliers are fully equipped to provide custom-cut or custom-manufactured strips to your exact specifications.

The "Standard" vs. The Reality

When specifying components like PTFE wear strips (also known as guide bands or bearing rings), it's easy to get caught searching for a standard part number. However, the nature of their function in hydraulic and pneumatic systems means that an exact fit is paramount.

Understanding Standard Roll Sizes

The dimensions you will most frequently encounter for off-the-shelf rolls are based on common hydraulic cylinder and rod diameters.

- Standard Widths: 5.8, 9.5, 14.8, 19.8, and 24.8 mm

- Standard Thickness: 2.5 mm

- Standard Length: 25-meter rolls

These rolls serve as the raw material stock from which application-specific rings are cut. It is rare for an entire 25-meter roll to be used in a single installation.

The Norm: Customization is King

The "standard" sizes are just a starting point. Modern manufacturing capabilities mean that getting the exact size you need is a routine process.

Suppliers can produce non-standard sizes, often with widths up to 50 mm and thicknesses up to 5 mm.

This flexibility comes from two main production methods:

- Cutting from Stock: Wear strips are precisely cut from large-format PTFE sheets, which can be over 1200x1200 mm (48x48 inches) and several inches thick.

- Extrusion: For specific profiles or very large quantities, a custom strip can be ram extruded to the exact width and thickness required.

This is why suppliers emphasize their CNC machines, skiving equipment, and extrusion lines—it signals their capability to deliver custom dimensions with tight tolerances.

Material Choice: A Critical Factor Beyond Size

The dimensions of the strip are only half of the equation. The material composition is just as critical for performance and longevity.

Virgin PTFE

Virgin (unfilled) PTFE offers the lowest coefficient of friction. It is ideal for applications where lubricity is the primary concern and mechanical loads are relatively low.

Filled PTFE Grades

For most hydraulic and pneumatic guide applications, a filled grade of PTFE is required to handle pressure and prevent extrusion.

- Bronze-Filled PTFE: Offers excellent compressive strength and wear resistance, making it a very common choice for hydraulic guide rings.

- Carbon-Filled PTFE: Provides good wear resistance and thermal conductivity, with improved strength over virgin PTFE.

- Other Fillers: Different fillers can be used to achieve specific properties, such as improved chemical resistance or dimensional stability.

The choice of material directly impacts the strip's ability to withstand side loads, high temperatures, and aggressive media.

Understanding the Trade-offs: Standard vs. Custom

Choosing between a standard roll size and a fully custom dimension involves balancing cost, lead time, and design precision.

Cost and Minimum Orders

Sourcing from a standard 2.5 mm thick roll is often the most cost-effective option, even if the width is custom-cut. Requesting a non-standard thickness or a custom-extruded profile may involve higher costs or minimum order quantities (MOQs) to justify a new production run.

Lead Time

Standard rolls and simple custom-cut strips from sheet stock are typically available with very short lead times. A fully custom-extruded profile will have a significantly longer lead time due to tooling and machine setup.

Design and Performance

Forcing your design to fit a standard width may be a false economy. An improperly sized wear strip can lead to excessive clearance, causing premature seal failure, or insufficient clearance, leading to binding and high friction. It is almost always better to specify the exact dimension your design requires.

Making the Right Choice for Your Goal

Base your specification strategy on your primary objective.

- If your primary focus is rapid prototyping or a one-off repair: Ask your supplier for strips cut from standard sheet stock. Provide them with the exact width, thickness, and cut length you need.

- If your primary focus is cost-optimization for a new design: Design your piston or rod groove to accommodate a standard thickness (e.g., 2.5 mm) and a common width if possible, but prioritize the correct functional fit above all else.

- If your primary focus is high-volume production: Work with a manufacturer to define the optimal custom-extruded profile and material (e.g., 40% Bronze-filled PTFE) for your application, balancing performance with unit cost.

Ultimately, you should feel empowered to specify the exact dimensions that your application demands, as the industry is built to accommodate these requests.

Summary Table:

| Standard Dimension | Typical Sizes |

|---|---|

| Thickness | 2.5 mm |

| Widths | 5.8, 9.5, 14.8, 19.8, 24.8 mm |

| Length | 25-meter rolls |

| Custom Capability | Up to 50 mm width, 5 mm thickness |

Get the Perfect Fit for Your Application

Don't compromise your design by forcing it to fit a standard size. KINTEK specializes in manufacturing precision PTFE components—including custom wear strips, seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors.

We provide custom fabrication from prototypes to high-volume orders, ensuring optimal performance and longevity for your hydraulic and pneumatic systems. Our expertise in both virgin and filled PTFE grades guarantees a solution tailored to your specific load, temperature, and chemical resistance requirements.

Contact KINTEK today to discuss your project and receive a quote for custom PTFE wear strips that meet your exact specifications.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are the key chemical properties of PTFE balls? Unmatched Chemical & Thermal Stability

- What precautions should be taken when drilling PTFE? Master Clean, Accurate Holes Every Time

- What is PTFE and why is it used for seals? The Ultimate Guide to High-Performance Sealing

- What are the advantages of glass-filled Teflon balls? Enhanced Strength & Wear Resistance for Demanding Applications

- What industries commonly use machined PTFE parts? Key Applications in Aerospace, Medical, and Semiconductor

- Why is lubrication important in PTFE machining? Master Heat Control for Precision Parts

- What are the main properties of PTFE that make it valuable as a sealing material? Discover the Ultimate Sealing Solution

- Why might an engineer choose to stick with standard O-rings for long-running applications? Maximize Reliability & Minimize Risk