In long-running applications, choosing a standard O-ring is a deliberate engineering decision rooted in risk management. Engineers select them for their unparalleled track record of reliability, global availability, and adherence to established design standards, which collectively minimize the potential for unforeseen failures over the entire operational life of the equipment.

The decision to use a standard O-ring is rarely about finding the cheapest or easiest component. It is a strategic choice that prioritizes long-term operational certainty and predictable system performance over the potential, but unproven, benefits of a custom solution.

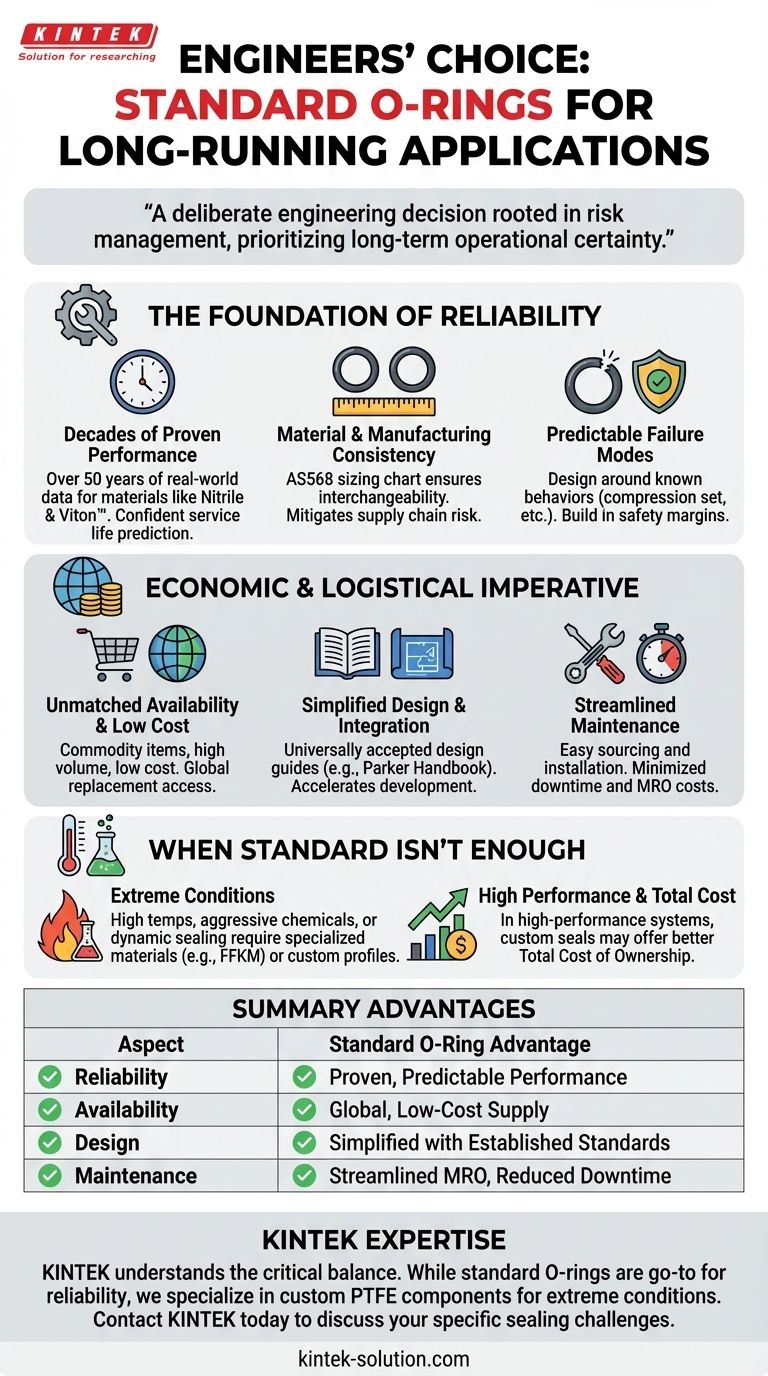

The Foundation of Reliability: Why "Standard" Matters

For equipment that must operate for years or decades, predictability is the most valuable attribute. Standard O-rings offer a level of predictability that custom or niche solutions cannot match.

Decades of Proven Performance

Standard O-rings, especially those with common material specifications like Nitrile (Buna-N) or Viton™ (FKM), have been used in countless applications for over 50 years. This extensive history provides a massive database of real-world performance, allowing engineers to confidently predict service life.

Material and Manufacturing Consistency

Standardization, such as the AS568 sizing chart, ensures interchangeability and consistency. An engineer can be confident that a part from one reputable manufacturer will perform identically to a part from another, which is critical for mitigating supply chain risk over a long product lifecycle.

Predictable Failure Modes

Experienced engineers understand precisely how standard O-rings behave under stress. They can design around well-documented failure modes like compression set, extrusion, or chemical swell, building in appropriate safety margins to ensure the seal outlasts its required service interval.

The Economic and Logistical Imperative

The practical realities of cost, manufacturing, and maintenance often favor the simplicity of a standard component, especially when multiplied over thousands of units or decades of service.

Unmatched Availability and Low Cost

Standard O-rings are commodity items, produced in high volumes by numerous manufacturers. This leads to low unit costs and ensures that replacements are readily available anywhere in the world, which is a crucial consideration for globally deployed equipment.

Simplified Design and Integration

Engineers can rely on universally accepted design guides, such as the Parker O-Ring Handbook. This eliminates the need for costly and time-consuming custom gland design and testing, dramatically accelerating the development process and reducing the risk of design error.

Streamlined Maintenance

Using a standard component simplifies maintenance, repair, and overhaul (MRO) operations. Technicians can easily source and install replacements without needing specialized parts or knowledge, minimizing downtime and operational costs.

Understanding the Trade-offs and Risks

While standard O-rings are a default choice for many applications, they are not a universal solution. An objective analysis requires acknowledging their limitations.

When Standard Isn't Enough

For applications involving extreme temperatures, aggressive chemicals, or high-pressure dynamic sealing, a standard O-ring may not be sufficient. In these cases, a specialized material (like FFKM) or a custom seal profile is necessary to ensure safety and reliability.

The Risk of Complacency

The simplicity of the O-ring can lead to a lack of diligence. An engineer must still perform a rigorous analysis of the application's specific requirements—including fluid compatibility, temperature ranges, and gland surface finish—to prevent premature failure.

The Hidden Cost of "Good Enough"

In a high-performance system where even marginal gains in efficiency or longevity are valuable, a custom-engineered seal may provide a better total cost of ownership. Sticking with a standard part could be a false economy if it leads to lower performance or more frequent maintenance cycles.

Making the Right Choice for Your Application

The decision to use a standard O-ring should be based on a clear understanding of your project's primary objective.

- If your primary focus is maximum system reliability and cost control: A standard O-ring, made from a material with a proven history in a similar environment, is almost always the correct choice.

- If your application involves extreme conditions or demands zero-leak tolerance: A standard O-ring serves as a baseline for evaluation, but you must invest in testing specialized or custom seals to meet these rigorous requirements.

- If your goal is to push performance boundaries in a novel design: Begin with standard O-ring principles for prototyping, but anticipate that achieving optimal performance will likely require a custom-engineered sealing solution.

Ultimately, selecting a standard O-ring is an active engineering decision that prioritizes proven system dependability over component-level optimization.

Summary Table:

| Aspect | Standard O-Ring Advantage |

|---|---|

| Reliability | Decades of proven performance with predictable failure modes |

| Availability | Global supply chain with easy-to-source, low-cost replacements |

| Design | Simplified integration using established standards (e.g., AS568) |

| Maintenance | Streamlined MRO operations, minimizing downtime and costs |

Need a reliable sealing solution for your long-running application?

At KINTEK, we understand the critical balance between proven performance and custom requirements. While standard O-rings are the go-to for predictable reliability, many applications in the semiconductor, medical, laboratory, and industrial sectors demand custom-fabricated PTFE components for superior chemical resistance, purity, and performance in extreme conditions.

We specialize in precision production of PTFE seals, liners, and labware, offering custom fabrication from prototypes to high-volume orders. Whether your project calls for a standard solution or a custom-engineered component, our expertise ensures your system's long-term dependability.

Contact KINTEK today to discuss your specific sealing challenges and discover the optimal solution for your application's lifecycle.

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

People Also Ask

- What is the overall operating temperature range for PTFE seals, gaskets, and O-rings? Achieve Sealing Integrity from -200°C to +260°C

- What are the benefits of PTFE seals in terms of prototyping and production? Accelerate R&D and Ensure Elite Performance

- What makes PTFE stand out among materials used in sealing technology? Unmatched Chemical & Thermal Resistance

- What are the two temperature extremes discussed for PTFE seals? Maximize Performance from Cryogenic to High-Heat

- What are the key properties of PTFE that make it suitable for sealing applications? | High-Performance Seals for Extreme Conditions