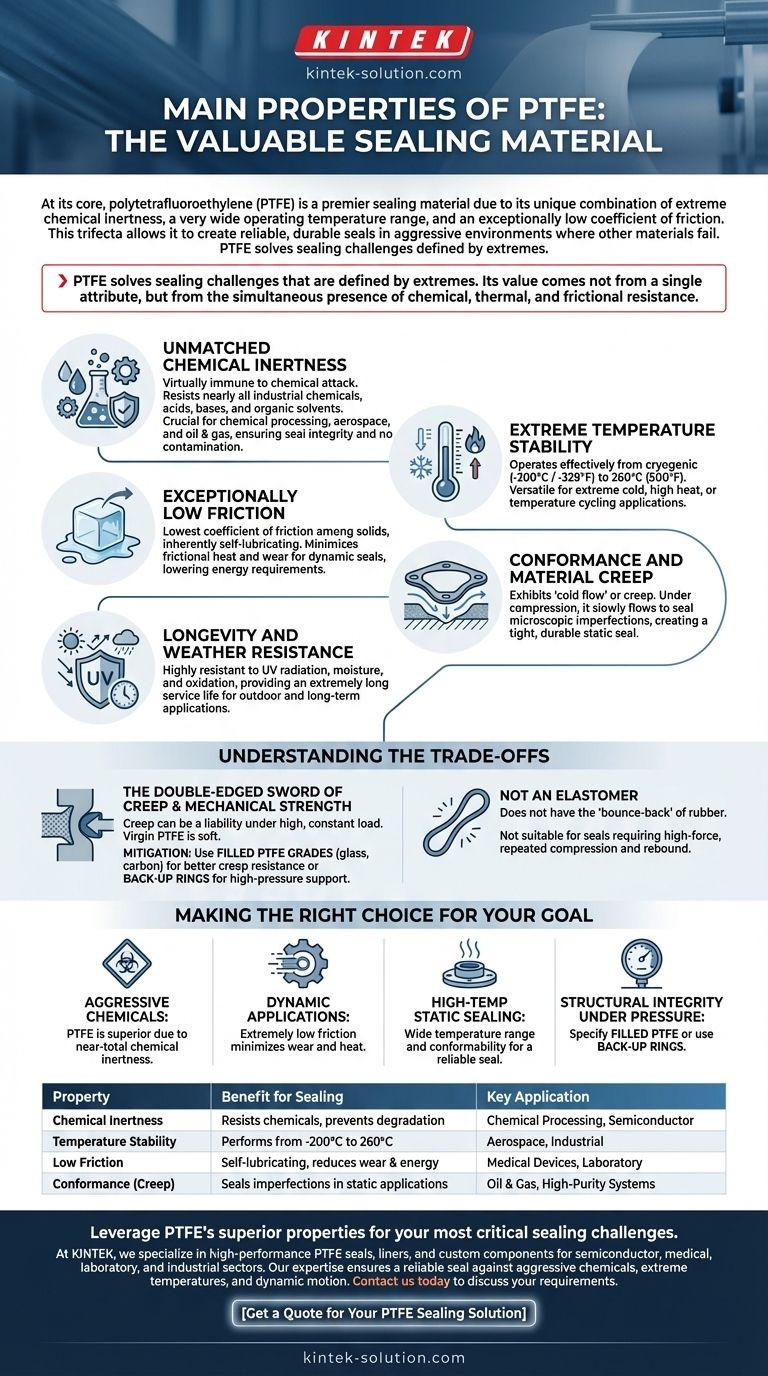

At its core, polytetrafluoroethylene (PTFE) is a premier sealing material because of its unique combination of extreme chemical inertness, a very wide operating temperature range, and an exceptionally low coefficient of friction. This trifecta of properties allows it to create a reliable and durable seal in aggressive environments where most other materials would quickly degrade and fail.

PTFE solves sealing challenges that are defined by extremes. Its value comes not from a single attribute, but from the simultaneous presence of chemical, thermal, and frictional resistance that makes it a default choice for the most demanding applications.

The Core Properties of PTFE for Sealing

To understand why PTFE is so effective, we must look at how its individual characteristics contribute to its overall performance as a seal. Each property solves a specific engineering problem.

Unmatched Chemical Inertness

PTFE is virtually immune to chemical attack. It resists nearly all industrial chemicals, including strong acids, bases, and organic solvents.

This property is critical for seals in chemical processing, aerospace, and oil & gas industries. It ensures the seal maintains its integrity and does not contaminate the process medium.

Extreme Temperature Stability

This material operates effectively across a vast temperature spectrum, typically from cryogenic levels around -200°C (-328°F) up to 260°C (500°F).

This allows a single material to be specified for applications involving extreme cold, high heat, or significant temperature cycling, providing a level of versatility that few other polymers can match.

Exceptionally Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. It is inherently self-lubricating.

For dynamic seals—those involving moving parts like rotating shafts or pistons—this is paramount. It minimizes frictional heat buildup, reduces wear on both the seal and the hardware, and lowers the energy required to operate the equipment.

Conformance and Material Creep

Unlike elastic materials that spring back, PTFE exhibits a property known as creep, or "cold flow." It lacks elastic memory.

While this sounds like a negative, it is highly beneficial for static seals like gaskets. Under compression, PTFE will slowly flow into and conform to microscopic imperfections on mating surfaces, creating an incredibly tight and durable seal that compensates for minor surface flaws.

Longevity and Weather Resistance

PTFE is highly resistant to environmental degradation. It is unaffected by UV radiation, moisture, and oxidation, giving it an extremely long service life.

This makes it ideal for outdoor applications or any system where long-term reliability is a primary concern.

Understanding the Trade-offs

No material is perfect, and being an effective advisor means acknowledging limitations. The very properties that make PTFE valuable also introduce specific design considerations.

The Double-Edged Sword of Creep

While excellent for creating a conforming static seal, the tendency to creep can be a liability under high, constant mechanical loads. The material may slowly deform and "extrude" out of place.

This is often mitigated by using filled PTFE grades, where materials like glass, carbon, or graphite are added to improve creep resistance and mechanical strength.

Mechanical Strength and Pressure

Virgin PTFE is a relatively soft material. In high-pressure applications, it can be forced out of the sealing gap.

This is why PTFE seals are often paired with stronger back-up rings made from materials like PEEK or metal. These rings provide structural support and prevent the PTFE from extruding under pressure.

Not an Elastomer

It is crucial not to confuse PTFE with rubber or other elastomers. It does not have the same "bounce-back" or resilience.

If your application requires a seal that must repeatedly compress and return to its original shape with high force, a traditional elastomer might be a better fit, assuming it can meet the chemical and thermal demands.

Making the Right Choice for Your Goal

Your specific application will determine which of PTFE's properties is most valuable. Use these points to guide your decision.

- If your primary focus is aggressive chemical exposure: PTFE is almost always the superior choice due to its near-total chemical inertness.

- If your primary focus is dynamic (moving) applications: PTFE's extremely low friction minimizes wear and heat buildup, making it ideal for rotating shafts or reciprocating rods.

- If your primary focus is high-temperature static sealing: PTFE's wide temperature range and ability to conform to surface imperfections ensure a reliable seal where elastomers would fail.

- If your primary focus is structural integrity under high pressure: You should specify a filled PTFE grade or design the system to include back-up rings to prevent extrusion.

Ultimately, understanding these core properties allows you to leverage PTFE not just as a material, but as a robust solution for your most demanding sealing challenges.

Summary Table:

| Property | Benefit for Sealing | Key Application |

|---|---|---|

| Chemical Inertness | Resists nearly all chemicals, preventing degradation and contamination. | Chemical Processing, Semiconductor |

| Temperature Stability | Performs from -200°C to 260°C, ideal for extreme heat or cold. | Aerospace, Industrial |

| Low Friction | Self-lubricating, reduces wear and energy use in dynamic applications. | Medical Devices, Laboratory |

| Conformance (Creep) | Flows to seal surface imperfections in static applications. | Oil & Gas, High-Purity Systems |

Leverage PTFE's superior properties for your most critical sealing challenges. At KINTEK, we specialize in the precision manufacturing of high-performance PTFE seals, liners, and custom components. Whether you need a standard solution or a custom-fabricated part for the semiconductor, medical, laboratory, or industrial sectors, our expertise ensures a reliable seal that withstands aggressive chemicals, extreme temperatures, and dynamic motion.

Contact us today to discuss your specific requirements and let our team deliver a solution that enhances your system's reliability and performance.

Get a Quote for Your PTFE Sealing Solution

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability