When drilling Polytetrafluoroethylene (PTFE), the most critical precautions are to use exceptionally sharp tools, maintain moderate cutting speeds to prevent melting, and apply minimal clamping pressure to avoid deforming the material. These steps are essential to manage PTFE's unique combination of softness, low thermal conductivity, and high thermal expansion, which make it prone to inaccuracy if machined improperly.

The core challenge with PTFE is not its hardness, but its inherent softness and sensitivity to heat. Successful drilling depends entirely on minimizing heat generation and physical stress on the material.

Understanding PTFE's Unique Machining Challenges

To drill PTFE accurately, you must first understand why it behaves differently than metals or even other plastics. Its properties demand a specific approach that prioritizes finesse over force.

The Problem of Softness and Stress Creep

PTFE is an incredibly soft material that can easily be compressed or deformed. Applying excessive pressure from clamps or vices will distort the workpiece.

This property, known as stress creep, means the material will slowly deform under a constant load. When the pressure is released after drilling, the material can "spring back," often resulting in a hole that is smaller than the drill bit used to create it.

The Impact of High Thermal Expansion

PTFE has a very high coefficient of thermal expansion and does not conduct heat well. Friction from a dull drill bit or excessive speed generates heat that becomes trapped at the cutting point.

This localized heat causes the material to expand significantly, leading to an inaccurate hole size. In severe cases, it can cause the PTFE to melt and weld to the drill bit, ruining both the tool and the workpiece.

The Challenge of Chip Evacuation

Because PTFE is so soft, it produces long, stringy, or gummy chips rather than the brittle chips seen with harder plastics.

These chips can easily wrap around the drill bit and clog the flutes. Clogged flutes prevent effective cutting, dramatically increase friction, and lead to the heat buildup discussed above.

A Practical Guide to Drilling PTFE

With a clear understanding of the material's properties, you can adopt specific techniques to ensure a clean, accurate result.

Tool Selection is Paramount

Your primary tool should be a high-speed steel (HSS) drill bit. It must be extremely sharp with a polished surface. A polished, sharp edge shears the material cleanly rather than pushing it, which minimizes friction and heat.

Calibrate Speeds and Feeds

Use moderate cutting speeds and a consistent feed rate. High RPMs are the most common cause of failure, as they instantly generate excessive heat. Start slow and observe the chip formation; you are looking for a clean curl, not a melted mess.

Ensure Perpendicular Alignment

Always ensure the drill is perfectly perpendicular to the workpiece. Because PTFE is so soft, any off-axis pressure will cause the drill bit to "drift" or wander, resulting in a misshapen or misplaced hole. A drill press is highly recommended over a handheld drill.

Apply Minimal Clamping Pressure

Secure the PTFE part without compressing it. Use fixtures with large, flat surfaces to distribute the clamping force evenly. The goal is to hold the part firmly enough to prevent movement, but gently enough to avoid any distortion.

Common Pitfalls and How to Avoid Them

Even with the right approach, several common mistakes can compromise the quality of your work. Being aware of them is the first step to avoiding them.

Avoiding Hole Inaccuracy

Do not assume a 1/4" drill bit will produce a 1/4" hole. Due to material spring-back and thermal effects, the final hole is often slightly undersized. If tight tolerances are required, plan to drill slightly undersized and then use a sharp reamer for the final pass.

Preventing Melting and Burrs

If you see any evidence of melting or significant burring around the hole's edge, stop immediately. This is a clear sign that your drill is dull, your speed is too high, or your chips are not evacuating properly.

Respecting the Material's Softness

PTFE requires very little force to cut. If you feel you need to push the drill through the material, something is wrong. Let the sharpness of the tool do the work.

How to Apply This to Your Project

Your specific approach should be guided by your project's primary goal.

- If your primary focus is dimensional accuracy: Prioritize a brand-new, sharp HSS drill bit, use very slow RPMs, and plan for a final reaming step to achieve the exact size.

- If your primary focus is a clean finish: Concentrate on ensuring constant chip evacuation by pecking the drill (drilling a short distance, then retracting to clear chips) and using a polished tool.

- If you are new to machining PTFE: Practice on a piece of scrap material first to find the optimal speed that produces a clean chip without any signs of melting.

By working with PTFE's unique properties instead of against them, you can achieve precise and clean results consistently.

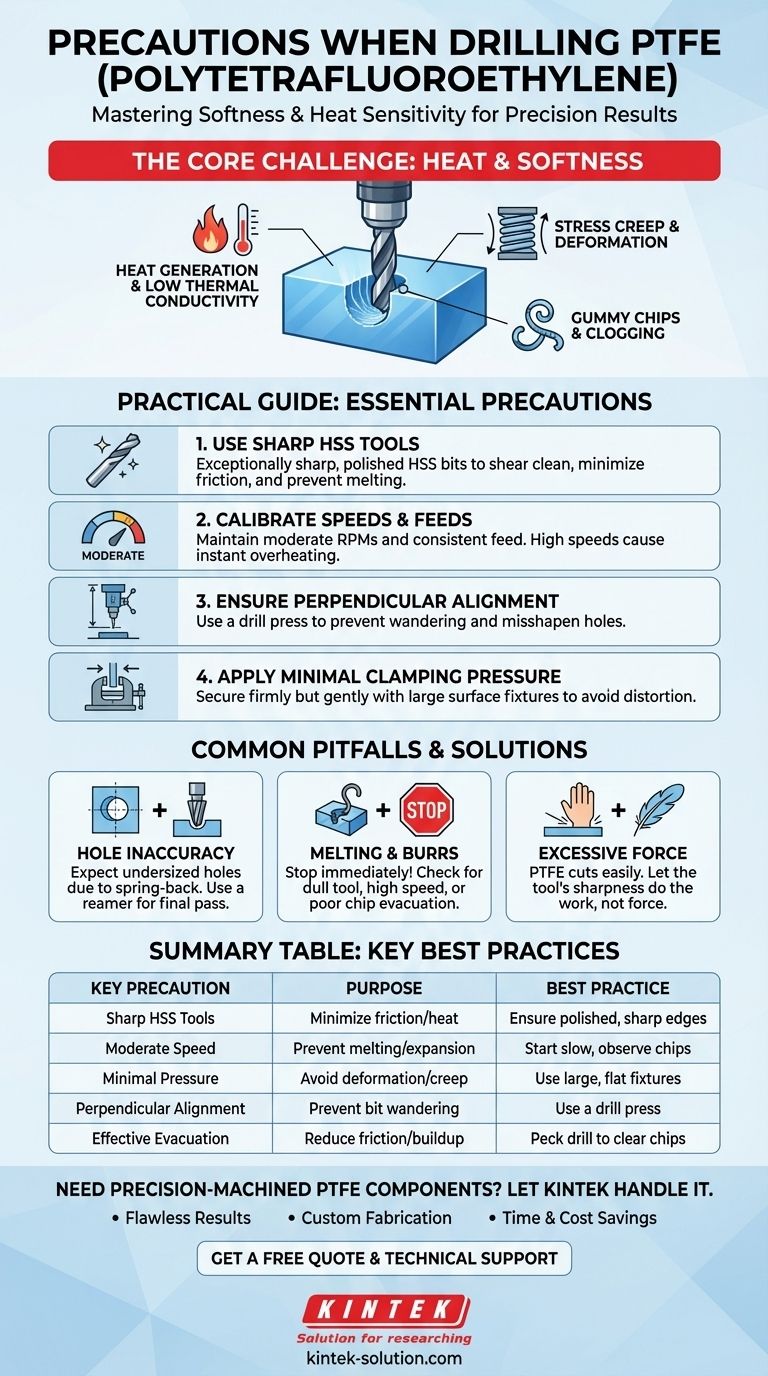

Summary Table:

| Key Precaution | Purpose | Best Practice |

|---|---|---|

| Use Sharp HSS Drill Bits | Minimize friction and heat generation | Ensure polished, sharp edges for clean shearing |

| Moderate Cutting Speed | Prevent PTFE melting and thermal expansion | Start slow, observe chip formation |

| Minimal Clamping Pressure | Avoid material deformation and stress creep | Use fixtures with large, flat surfaces |

| Ensure Perpendicular Alignment | Prevent drill bit wandering | Use a drill press for accuracy |

| Effective Chip Evacuation | Reduce friction and heat buildup | Peck drill to clear stringy chips |

Need Precision-Machined PTFE Components? Let KINTEK Handle It.

Drilling PTFE in-house can be challenging and risky for your valuable projects. Why not leverage our expertise? KINTEK specializes in manufacturing high-precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors.

We ensure:

- Flawless Results: Our advanced techniques prevent common issues like melting, burrs, and dimensional inaccuracies.

- Custom Fabrication: From prototypes to high-volume orders, we deliver components tailored to your exact specifications.

- Time and Cost Savings: Avoid trial-and-error machining and focus on your core work.

Contact us today for a consultation and let us provide you with reliably machined PTFE parts that meet your highest standards.

Get a Free Quote & Technical Support

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What materials are used in the construction of PTFE lined ball valves? A Guide to Corrosion-Resistant Components

- What are the key properties of PTFE Teflon O-rings? Unmatched Chemical & Thermal Resistance

- What is the temperature range for PTFE piston seals? Unlock the True Limits for Your Application

- What are the specifications of a high-pressure, low-speed PTFE seal profile? Handle 3,000 psi with Confidence

- What risks are associated with improper bonding of PTFE liners? Prevent Catastrophic Bearing Failure

- How does PTFE's low friction coefficient benefit mechanical systems? Boost Efficiency & Extend Lifespan

- What are the two main methods used to manufacture PTFE gaskets? Ensure Optimal Sealing Performance

- In what types of systems is PTFE packing commonly used? Essential Sealing for Extreme Chemical & Temperature Environments