At its core, Polytetrafluoroethylene (PTFE) is a high-performance fluoropolymer defined by a unique combination of extreme properties. It is most renowned for its exceptional chemical resistance, an incredibly low coefficient of friction that gives it a non-stick quality, and stability across a very wide range of temperatures. These characteristics make it a go-to material for demanding industrial, medical, and electrical applications.

PTFE is best understood as a material of extremes. Its world-class performance in chemical inertness, temperature resistance, and electrical insulation is balanced by its inherent softness and average mechanical strength, making it a specialized solution rather than a general-purpose structural plastic.

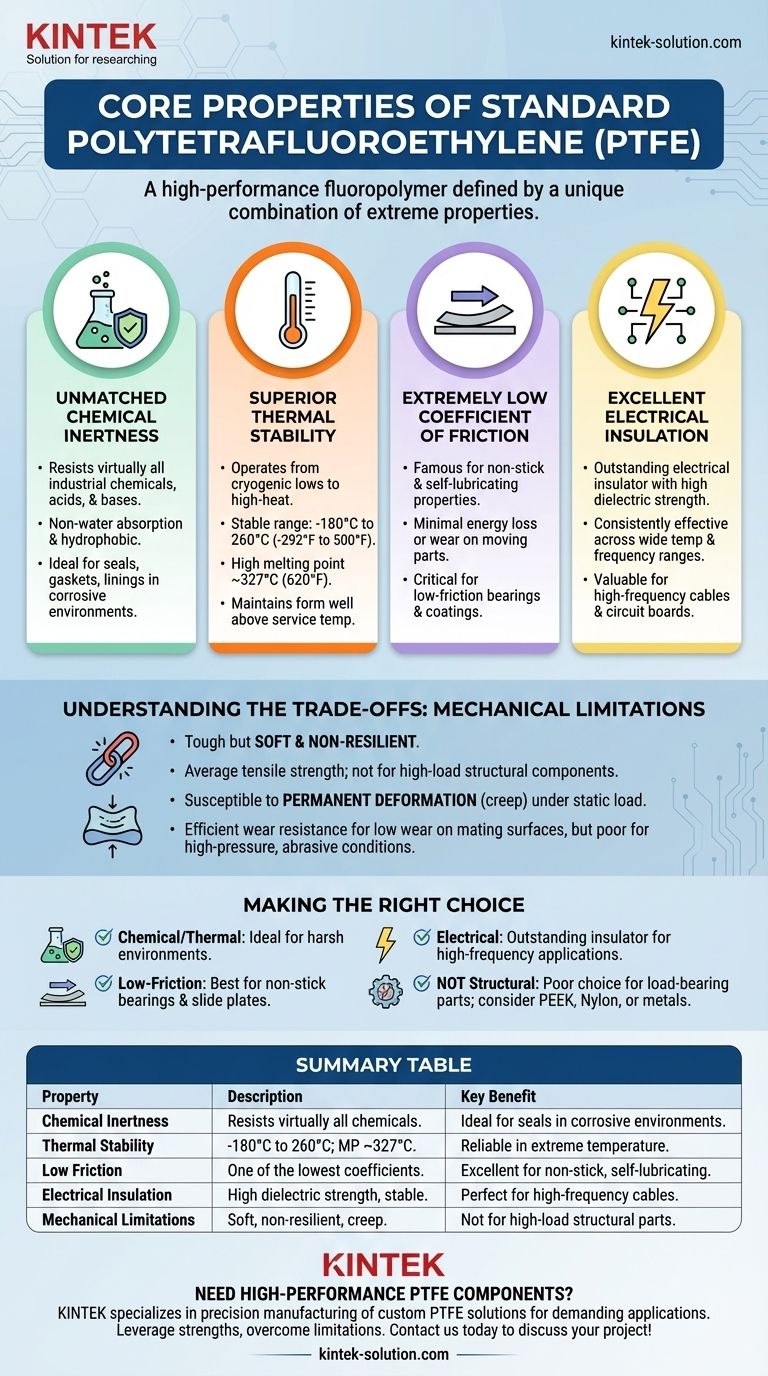

Core Properties of PTFE: A Detailed Breakdown

To determine if PTFE is the right material for your application, you must understand how its distinct properties translate into real-world performance. We can group its primary characteristics into four key areas.

Unmatched Chemical Inertness

PTFE is one of the most chemically resistant materials known. It is virtually inert and will not react with the vast majority of industrial chemicals, acids, and bases.

This property makes it an ideal choice for seals, gaskets, linings, and tubing that will be exposed to corrosive fluids. Its non-water absorption and hydrophobic nature also prevent it from swelling or degrading in the presence of moisture.

Superior Thermal Stability

PTFE performs reliably across an exceptionally broad temperature range. It remains functional and stable in environments from cryogenic lows up to high-heat applications.

Most grades operate effectively from -180°C to 260°C (-292°F to 500°F). Its high melting point of around 327°C (620°F) ensures it maintains its solid form well above its maximum service temperature.

Extremely Low Coefficient of Friction

PTFE has one of the lowest coefficients of friction of any solid material, which is why it is famous for its non-stick and self-lubricating properties.

This allows moving parts to slide against it with minimal energy loss or wear. This is critical for applications like low-friction bearings, non-stick coatings, and components where external lubrication is impractical or undesirable.

Excellent Electrical Insulation

PTFE is an outstanding electrical insulator with high dielectric strength and high volume resistivity. It effectively resists the passage of electric current.

Crucially, its insulating properties remain consistent across a wide range of temperatures and frequencies. This makes it a valuable material for high-frequency applications like coaxial cable insulation and circuit boards.

Understanding the Trade-offs

No material is perfect, and PTFE's unique strengths come with important limitations that you must consider. Its primary trade-offs are mechanical in nature.

Mechanical Limitations

PTFE is a tough and flexible material, but it is also soft and non-resilient. It has only average tensile strength and is not suitable for high-load structural components.

While it has a large tolerance for permanent deformation (creep) under a static load, it will not return to its original shape. This makes it a poor choice for applications requiring structural rigidity or elastic recovery.

Wear Resistance Context

Standard PTFE is noted for having efficient wear resistance and causing low wear on mating metal surfaces. This makes it ideal for bearing pads and sliding applications where protecting the more expensive metal component is paramount.

However, its inherent softness means it may not be suitable for high-pressure, abrasive wear conditions where a harder material would be required. Fillers like glass or carbon can be added to PTFE to significantly improve its mechanical strength and wear properties for these more demanding roles.

Making the Right Choice for Your Goal

Selecting PTFE depends entirely on whether its unique advantages align with the primary demands of your project.

- If your primary focus is sealing in harsh chemical or high-temperature environments: PTFE is an industry-standard choice due to its unmatched chemical inertness and thermal stability.

- If your primary focus is creating a low-friction or non-stick surface: PTFE is one of the best materials available for bearings, slide plates, and coatings where minimal resistance is critical.

- If your primary focus is a load-bearing structural component: PTFE is a poor choice; you should consider engineering plastics like PEEK, Nylon, or metals.

- If your primary focus is high-frequency electrical insulation: PTFE is an outstanding insulator that maintains its properties reliably across a wide range of operating conditions.

Ultimately, leveraging PTFE successfully means deploying it where its elite properties can solve a specific, demanding challenge that lesser materials cannot.

Summary Table:

| Property | Description | Key Benefit |

|---|---|---|

| Chemical Inertness | Resists virtually all industrial chemicals, acids, and bases. | Ideal for seals and linings in corrosive environments. |

| Thermal Stability | Operates from -180°C to 260°C; melting point ~327°C. | Reliable performance in extreme temperature applications. |

| Low Friction | One of the lowest coefficients of friction of any solid. | Excellent for non-stick, self-lubricating bearings and components. |

| Electrical Insulation | High dielectric strength, stable across temperatures/frequencies. | Perfect for high-frequency cable insulation and circuit boards. |

| Mechanical Limitations | Soft, non-resilient, with average tensile strength and creep. | Not suitable for high-load structural parts; consider filled grades. |

Need High-Performance PTFE Components?

PTFE's unique properties make it the ideal solution for demanding applications in the semiconductor, medical, laboratory, and industrial sectors. At KINTEK, we specialize in the precision manufacturing of custom PTFE components—from seals and liners to complex labware.

We help you leverage PTFE's strengths while engineering solutions to overcome its limitations. Whether you need a prototype or a high-volume order, our expertise ensures you get the right part for your specific chemical, thermal, or friction-related challenge.

Contact KINTEK today to discuss your project requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- PTFE Chemical Solvent Sampling Spoon

People Also Ask

- What should be considered when choosing a manufacturer for PTFE-lined bearings? Ensure Long-Term Reliability and Performance

- What is the purpose of comparing spring energized PTFE seals to elastomeric seals? A Guide to Choosing the Right Seal

- What advantages do PTFE coatings offer in terms of durability and maintenance? Maximize Component Lifespan

- What are the key properties of PTFE that make it suitable for machining? Leverage Its Unique Qualities for Precision Components

- What are PTFE compounds and how are they used? Enhance Performance for Demanding Applications

- What makes Teflon gland fillers effective for sealing applications in the chemical industry? Superior Chemical Resistance and Reliability

- Why are Teflon rods preferred in the food and pharmaceutical sectors? Ensure Purity and Compliance

- What is the temperature range that PTFE gaskets can withstand? A Guide from -200°C to +260°C