In short, Teflon rods are preferred in the food and pharmaceutical industries because they are exceptionally non-toxic, chemically inert, and feature a non-stick surface that is easy to sterilize. This unique combination of properties directly addresses the non-negotiable requirements for product purity and safety in these highly regulated sectors, making Teflon (PTFE) a benchmark material for components that contact consumables.

The decision to use Teflon is not merely about material preference; it is a strategic choice to mitigate risk. Its inherent properties—purity, cleanability, and chemical resistance—are fundamental to ensuring regulatory compliance, preventing contamination, and maintaining operational uptime.

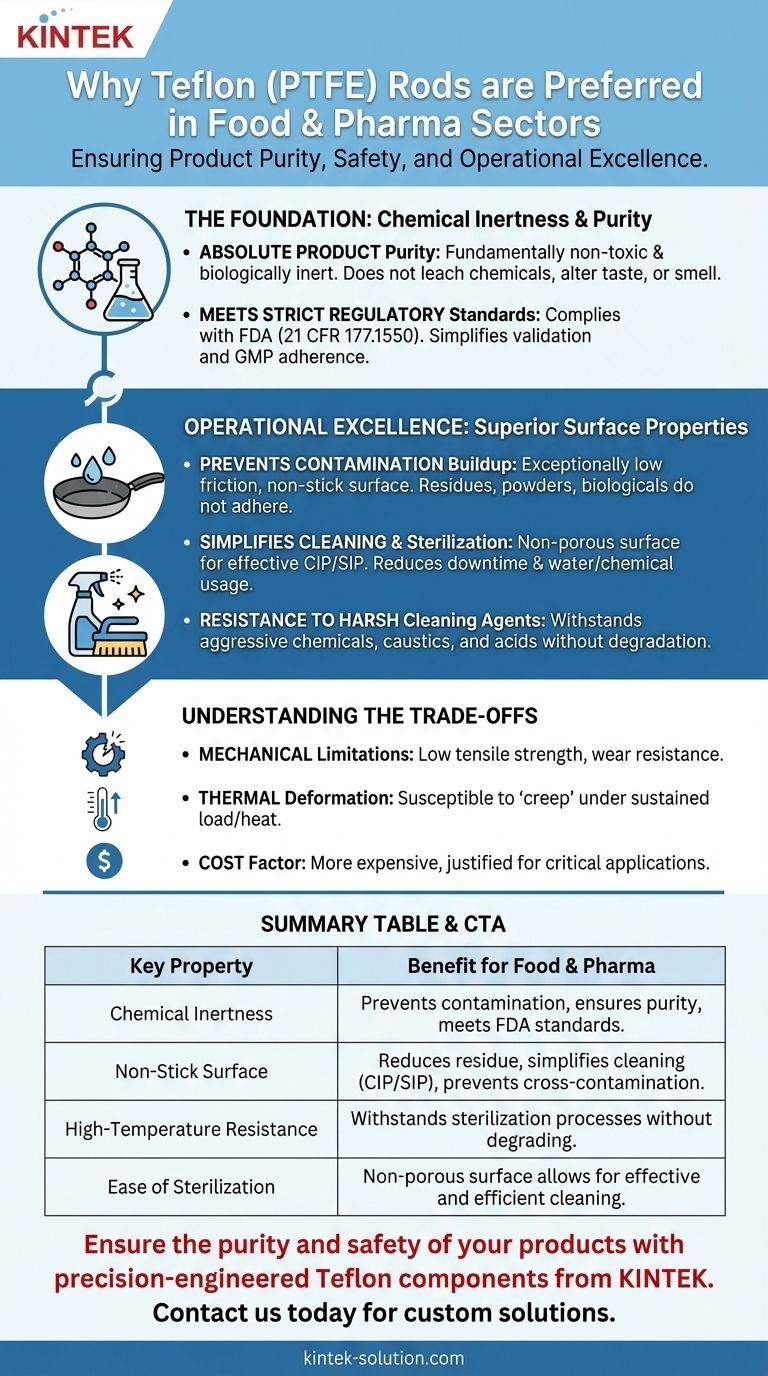

The Foundation: Why Chemical Inertness is Paramount

In environments where consumer safety is the primary concern, the materials used cannot be a source of contamination. The core value of Teflon, or Polytetrafluoroethylene (PTFE), begins with its extreme chemical inertness.

Ensuring Absolute Product Purity

Teflon is fundamentally non-toxic and biologically inert. Its molecular structure is incredibly stable, meaning it does not leach chemicals or impurities into the products it touches, whether they are food ingredients, sensitive chemical compounds, or finished pharmaceuticals.

This prevents any alteration of the product's taste, smell, color, or chemical composition, ensuring the final item delivered to the consumer is exactly as intended.

Meeting Strict Regulatory Standards

This chemical purity is not just a desirable feature; it is a legal requirement. Materials used in food and drug processing must comply with stringent regulations.

Teflon grades are available that meet standards set by the Food and Drug Administration (FDA), specifically 21 CFR 177.1550. Using a compliant material like Teflon simplifies the validation process for equipment and ensures adherence to Good Manufacturing Practices (GMP).

Operational Excellence Through Superior Surface Properties

Beyond its chemical makeup, Teflon's physical surface characteristics provide significant operational advantages that are critical in production environments.

Preventing Contamination Buildup

Teflon is famous for having one of the lowest coefficients of friction of any solid material. This creates an exceptionally smooth, non-stick (hydrophobic) surface.

As a result, food products, sticky powders, and biological materials do not adhere to it. This prevents the buildup of residues that could harbor bacteria or cross-contaminate subsequent batches.

Simplifying Cleaning and Sterilization

Because nothing sticks to Teflon, cleaning is dramatically faster and more effective. Its non-porous surface has no microscopic cavities where contaminants can hide.

This is invaluable for Clean-in-Place (CIP) and Sterilize-in-Place (SIP) systems. The ease of cleaning reduces downtime between production runs, minimizes water and chemical usage, and guarantees a higher level of sanitation.

Resistance to Harsh Cleaning Agents

The same chemical inertness that protects the product also protects the component itself. Teflon rods can withstand the aggressive chemicals, caustics, and acids commonly used for industrial-strength cleaning and sterilization without degrading, cracking, or corroding.

Understanding the Trade-offs

While Teflon is an outstanding material, it is not a universal solution. An objective assessment requires understanding its limitations.

Mechanical Limitations

Teflon is a relatively soft material with low tensile strength and wear resistance compared to other engineering plastics like UHMW-PE. It is not suitable for high-load structural applications where mechanical strength is the primary requirement.

Thermal Deformation (Creep)

Although Teflon has a wide operating temperature range, it is susceptible to "creep," or deformation under a sustained load, especially at elevated temperatures. This must be considered in the design of parts like seals and gaskets that are under constant pressure.

Cost Factor

Teflon is often a more expensive material compared to other plastics. Its use is justified when its specific properties—purity, chemical resistance, and non-stick surface—are critical for the application's success and safety. For simple, non-contact structural parts, a less expensive material may be more appropriate.

Making the Right Choice for Your Application

Selecting the correct material requires aligning its properties with the specific demands of the task.

- If your primary focus is direct food or drug contact: Teflon is the gold standard, ensuring ultimate purity, cleanability, and compliance.

- If your primary focus is high-wear abrasion resistance (e.g., non-contact guide rails): A material like UHMW-PE might offer a more durable and cost-effective solution.

- If your primary focus is a high-temperature and chemically harsh environment: Teflon's thermal stability and inertness make it a superior choice over most other plastics.

Ultimately, choosing Teflon is an investment in the safety, integrity, and efficiency of your production process.

Summary Table:

| Key Property | Benefit for Food & Pharma |

|---|---|

| Chemical Inertness | Prevents contamination, ensures product purity, meets FDA standards. |

| Non-Stick Surface | Reduces residue buildup, simplifies cleaning (CIP/SIP), prevents cross-contamination. |

| High-Temperature Resistance | Withstands sterilization processes without degrading. |

| Ease of Sterilization | Non-porous surface allows for effective and efficient cleaning. |

Ensure the purity and safety of your products with precision-engineered Teflon components from KINTEK.

We specialize in manufacturing high-quality PTFE rods, seals, liners, and labware for the semiconductor, medical, laboratory, and industrial sectors. Our commitment to precision production and custom fabrication—from prototypes to high-volume orders—ensures you get components that meet the strictest regulatory requirements.

Contact us today to discuss your specific needs and let our experts provide a solution that guarantees compliance and operational excellence.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications