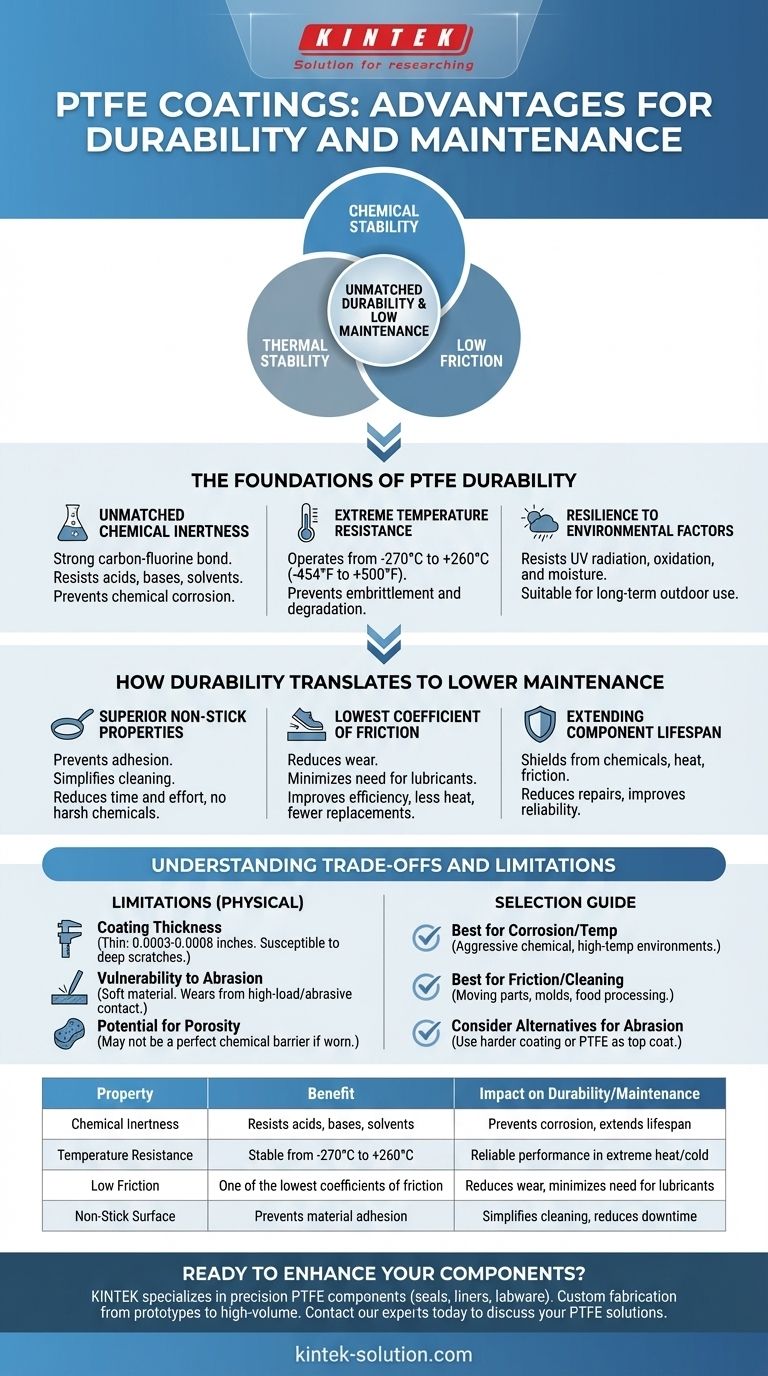

At its core, the advantages of PTFE coatings in durability and maintenance stem directly from its fundamental chemical stability. This molecular structure creates an exceptionally non-reactive and low-friction surface that is highly resistant to extreme temperatures, chemical attack, and environmental weathering. This inherent resilience dramatically extends the life of components and significantly reduces the effort required for cleaning and upkeep.

The primary benefit of PTFE is not one single feature, but a powerful combination of properties—thermal stability, chemical inertness, and low friction—that work in synergy. This creates a highly durable, low-maintenance surface that protects the underlying component from the most common causes of degradation.

The Foundations of PTFE Durability

To understand why PTFE coatings reduce maintenance, we must first examine the sources of their exceptional durability. The material is not simply tough; it is resilient in multiple, distinct ways.

Unmatched Chemical Inertness

The bond between carbon and fluorine atoms in PTFE is one of the strongest in organic chemistry. This makes the coating almost universally inert.

It effectively resists damage from most acids, bases, and solvents, preventing the chemical corrosion that degrades many other materials over time.

Extreme Temperature Resistance

PTFE coatings maintain their integrity across an incredibly wide operating temperature range, typically from -270°C to +260°C (-454°F to +500°F).

This stability prevents the material from becoming brittle in extreme cold or degrading in high heat, ensuring reliable performance in demanding thermal environments.

Resilience to Environmental Factors

PTFE is highly resistant to weathering. It is not degraded by UV radiation, oxidation, or moisture, making it suitable for long-term outdoor applications.

Unlike many plastics, it will not discolor, weaken, or become brittle when exposed to the elements, ensuring a long and predictable service life.

How Durability Translates to Lower Maintenance

The inherent durability of PTFE directly leads to tangible maintenance benefits, saving time, labor, and cost over the lifespan of the coated part.

Superior Non-Stick Properties

PTFE is best known for its non-stick, or non-adhesive, surface. This means that other substances have great difficulty sticking to it.

This property simplifies cleaning operations immensely, as materials can be wiped away easily without harsh chemicals or abrasive tools. This reduces both cleaning time and the risk of damaging the component.

The Lowest Coefficient of Friction

PTFE possesses one of the lowest coefficients of friction of any known solid material, often compared to wet ice on wet ice.

For moving parts, this lubricity reduces wear and tear, minimizes the need for liquid lubricants, and allows machinery to operate more efficiently. Less friction means less heat, less wear, and fewer part replacements.

Extending Component Lifespan

By shielding the underlying material from chemicals, heat, and friction, a PTFE coating acts as a protective barrier.

This protection prolongs the operational life of the equipment, reducing the frequency of costly repairs and replacements and improving overall reliability.

Understanding the Trade-offs and Limitations

While powerful, PTFE is not a universal solution. An objective assessment requires understanding its limitations, which are primarily physical rather than chemical.

Coating Thickness and Application

PTFE coatings are applied in very thin layers, often between 0.0003 and 0.0008 inches. This is beneficial as it does not typically affect part tolerances.

However, this thinness means that a deep scratch or gouge can compromise the protective barrier and expose the substrate material underneath.

Vulnerability to Abrasion

PTFE's primary strength is low friction, not high hardness. It is a relatively soft material.

It can be susceptible to wear from high-load, abrasive contact. While it prevents things from sticking, it can be worn away by persistent, forceful scraping or contact with hard, sharp particles.

Potential for Porosity

While chemically inert, the coating itself can be porous. This is generally not an issue, but if the coating wears down easily in a specific application, it may not provide a perfect, long-term chemical barrier.

Selecting PTFE for Your Specific Needs

Your application's specific demands will determine if PTFE's unique profile of benefits is the right fit.

- If your primary focus is corrosion and temperature resistance: PTFE is an exceptional choice for protecting parts in chemically aggressive or high-temperature environments.

- If your primary focus is reducing friction and simplifying cleaning: The non-stick and low-friction properties of PTFE are ideal for moving parts, molds, and food processing equipment.

- If your primary concern is heavy physical abrasion or impact: Consider a harder coating material, or use PTFE as a top coat over a more durable base layer.

By understanding both its profound strengths and practical limitations, you can leverage PTFE coatings to achieve remarkable gains in durability and operational efficiency.

Summary Table:

| Property | Benefit | Impact on Durability/Maintenance |

|---|---|---|

| Chemical Inertness | Resists acids, bases, solvents | Prevents corrosion, extends lifespan |

| Temperature Resistance | Stable from -270°C to +260°C | Reliable performance in extreme heat/cold |

| Low Friction | One of the lowest coefficients of friction | Reduces wear, minimizes need for lubricants |

| Non-Stick Surface | Prevents material adhesion | Simplifies cleaning, reduces downtime |

Ready to enhance your components with durable, low-maintenance PTFE coatings?

KINTEK specializes in precision PTFE components (seals, liners, labware) for the semiconductor, medical, laboratory, and industrial sectors. Our custom fabrication services—from prototypes to high-volume orders—leverage PTFE's unique properties to protect your equipment, reduce operational costs, and extend service life.

Contact our experts today to discuss how our PTFE solutions can solve your specific durability and maintenance challenges.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining