At its core, Polytetrafluoroethylene (PTFE) is suitable for machining because of a unique combination of extreme slipperiness, high-temperature resistance, and chemical inertness. These properties allow it to be cut cleanly with minimal tool friction while maintaining its shape and integrity, making it ideal for creating precise, durable components.

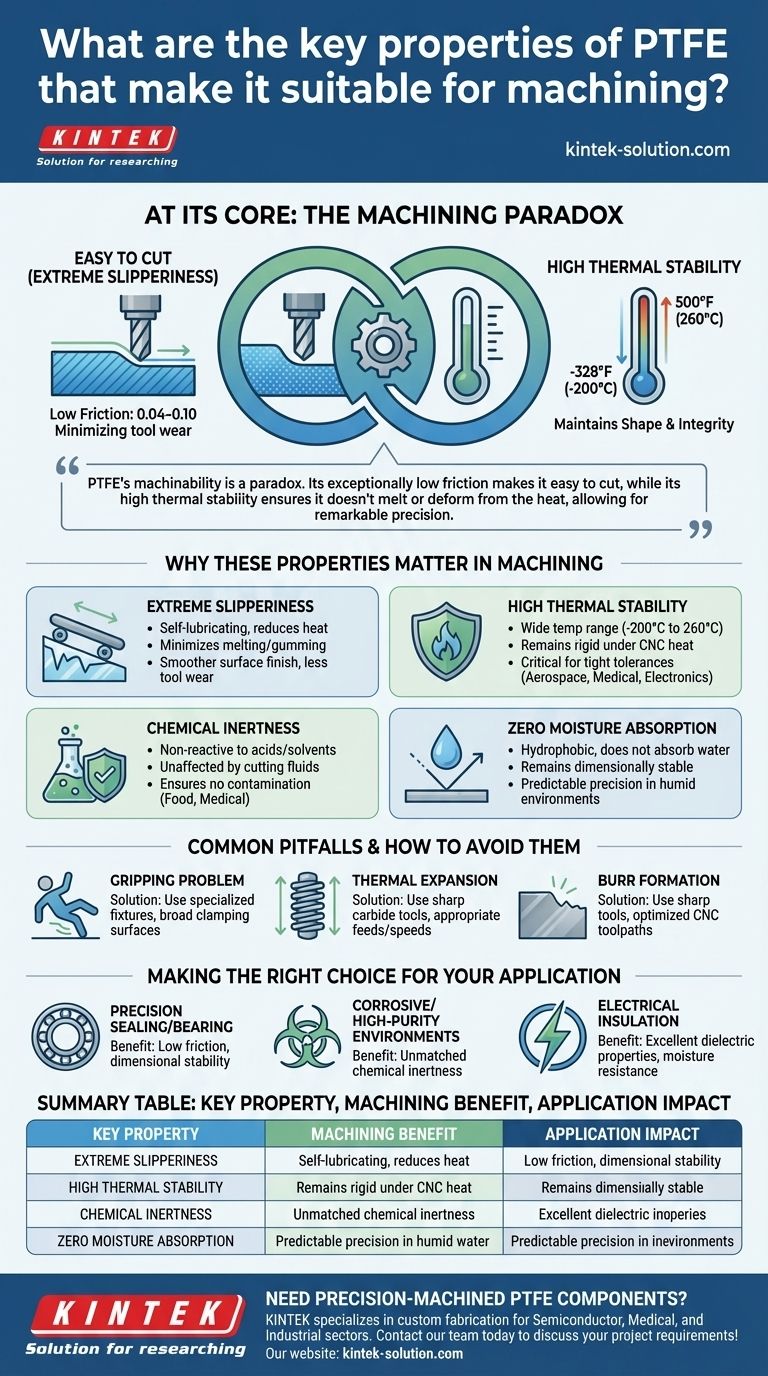

PTFE’s machinability is a paradox. Its exceptionally low friction makes it easy to cut, while its high thermal stability ensures it doesn't melt or deform from the heat of that same cutting process, allowing for remarkable precision.

Why These Properties Matter in Machining

Understanding how PTFE behaves is the key to successfully machining it. Its primary characteristics directly influence the tooling, techniques, and final quality of the part.

The Impact of Extreme Slipperiness

PTFE has one of the lowest coefficients of friction of any solid material, often cited between 0.04 and 0.10. This self-lubricating quality is a significant advantage during machining.

The low friction reduces the heat generated between the cutting tool and the material. This minimizes the risk of melting or gumming up, which is a common issue with other plastics.

This property also results in less tool wear and allows for a smoother, cleaner surface finish on the final part with less effort.

The Role of Thermal Stability

PTFE can withstand an incredibly wide temperature range, from as low as -328°F (-200°C) to a continuous operating temperature of 500°F (260°C).

This high melting point and stability mean the material remains rigid and dimensionally stable even when subjected to the localized heat of a CNC machine.

Because it doesn't easily warp or deform under heat, machinists can hold extremely tight tolerances, which is critical for components used in aerospace, medical, and electronics.

The Advantage of Chemical Inertness

PTFE is famously non-reactive and resistant to nearly all industrial acids, solvents, and chemicals.

While this is primarily a benefit for the final application, it also means the material will not be affected by any cutting fluids or coolants used during the machining process.

This chemical purity ensures there is no contamination of the material, a vital consideration for parts used in food processing or medical devices.

The Importance of Zero Moisture Absorption

PTFE is hydrophobic, meaning it does not absorb water.

Unlike materials like nylon which can swell and change dimensions in humid environments, PTFE remains stable. This predictability is essential for maintaining precision from raw stock to finished component.

Common Pitfalls and How to Avoid Them

While PTFE's properties make it highly machinable, they also introduce specific challenges that require careful management.

The Gripping Problem

The same low-friction quality that makes PTFE easy to cut also makes it difficult to hold securely in a machine vise or chuck.

The material can easily slip or vibrate if not fixtured properly, leading to inaccurate cuts. Using specialized fixtures with broad clamping surfaces is essential to prevent movement without denting the soft material.

Managing Thermal Expansion

Although thermally stable, PTFE has a relatively high rate of thermal expansion. If too much heat is generated from dull tools or aggressive cutting speeds, the part can expand during machining and then contract as it cools.

This can result in a finished part that is undersized and out of tolerance. Using extremely sharp, carbide-tipped tools and appropriate feeds and speeds is crucial to minimize heat input.

Preventing Burr Formation

As a relatively soft polymer, PTFE can be prone to developing fine burrs along cut edges.

Deburring these parts requires a careful secondary process. Using sharp tools and optimized toolpaths in a CNC machine helps minimize burr formation from the start.

Making the Right Choice for Your Application

Selecting PTFE is about aligning its unique properties with the demands of the final component.

- If your primary focus is precision sealing or bearing surfaces: PTFE's low friction and dimensional stability make it an ideal choice for creating parts that move against others with minimal wear.

- If your primary focus is use in corrosive or high-purity environments: Its unmatched chemical inertness ensures the component will not degrade or contaminate its surroundings.

- If your primary focus is electrical insulation: PTFE's excellent dielectric properties and resistance to moisture make it a superior material for insulators and high-frequency electronics.

By understanding these core properties and their practical implications, you can confidently leverage PTFE's unique advantages for your most demanding applications.

Summary Table:

| Key Property | Machining Benefit | Application Impact |

|---|---|---|

| Extreme Slipperiness | Reduces tool friction and heat, enabling clean cuts. | Ideal for seals, bearings, and low-friction parts. |

| High Thermal Stability | Maintains shape and tolerances under machining heat. | Suitable for high-temperature environments up to 260°C. |

| Chemical Inertness | Unaffected by cutting fluids; ensures part purity. | Perfect for medical, semiconductor, and corrosive settings. |

| Zero Moisture Absorption | Dimensions remain stable, ensuring precision. | Critical for components requiring exact tolerances. |

Need precision-machined PTFE components? KINTEK specializes in custom fabrication of PTFE seals, liners, and labware for the semiconductor, medical, and industrial sectors. Our expertise in managing PTFE's unique properties ensures your parts meet the highest standards for precision and durability—from prototypes to high-volume orders. Contact our team today to discuss your project requirements!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments