To put it simply, PTFE-lined ball valves are primarily used for reliable on/off control in pipelines that handle highly corrosive or high-purity media. Their main applications are found in demanding industrial environments like chemical processing, pharmaceutical manufacturing, and food and beverage production, where standard metal valves would quickly fail or contaminate the product.

The core function of a PTFE-lined ball valve isn't just to control flow; it's to create an impenetrable, chemically inert barrier. This lining protects the valve's metal body from aggressive fluids, ensuring both the longevity of the valve and the purity of the media passing through it.

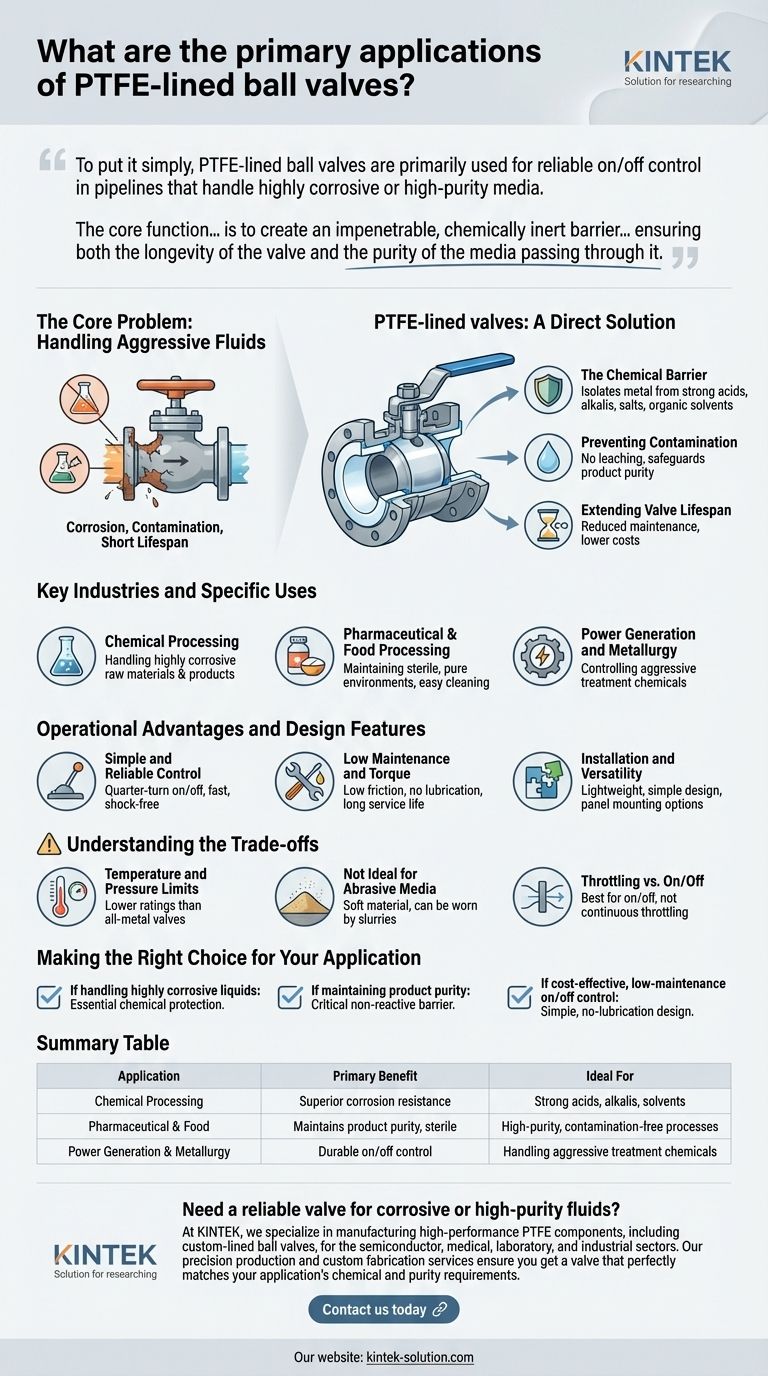

The Core Problem: Handling Aggressive Fluids

The fundamental challenge in many industrial processes is the safe and reliable transport of fluids that can corrode or degrade standard equipment. PTFE-lined valves are a direct solution to this problem.

The Chemical Barrier

The defining feature is that all surfaces that come into contact with the fluid are made of Polytetrafluoroethylene (PTFE). This lining acts as a shield, completely isolating the metal valve body from corrosive media like strong acids, alkalis, salts, and organic solvents.

Preventing Contamination

In industries such as pharmaceuticals or food and beverage, preventing contamination is just as important as preventing corrosion. The inert nature of the PTFE lining ensures that no metallic elements from the valve body can leach into the process fluid, safeguarding product purity.

Extending Valve Lifespan

By preventing direct chemical attack on the valve's structural components, the PTFE lining dramatically extends the service life of the valve in harsh operating conditions. This leads to reduced maintenance and lower replacement costs over time.

Key Industries and Specific Uses

The unique properties of PTFE make these valves indispensable across several key sectors. Their application is almost always tied to the chemical characteristics of the fluid being handled.

Chemical Processing

This is the most common application. PTFE-lined valves are standard in chemical plants for handling the raw materials and finished products that are often highly corrosive.

Pharmaceutical & Food Processing

These industries rely on PTFE-lined valves to maintain sterile and pure environments. The non-stick surface of PTFE also facilitates easier cleaning and prevents buildup within the valve.

Power Generation and Metallurgy

Various processes within these heavy industries use aggressive chemicals for treatment, cleaning, or extraction. PTFE-lined valves provide a durable solution for controlling these fluid streams.

Operational Advantages and Design Features

Beyond chemical resistance, the design of these valves offers several practical benefits for industrial operators.

Simple and Reliable Control

PTFE-lined ball valves are designed for quarter-turn (90-degree) on/off operation. This allows for fast and shock-free opening and closing, which can be done manually with a lever or automated with a pneumatic actuator.

Low Maintenance and Torque

The low-friction properties of PTFE mean that the valve operates with minimal torque and requires no lubrication. This translates to a long, maintenance-free service life.

Installation and Versatility

These valves are typically lightweight and feature a simple design, making them easy to install. Many models also include features like panel mounting capabilities for clean and organized integration into control systems.

Understanding the Trade-offs

While highly effective, it's crucial to understand the limitations of PTFE to ensure proper application. Objectivity requires acknowledging where these valves may not be the best fit.

Temperature and Pressure Limits

PTFE is a polymer, and as such, it has lower temperature and pressure ratings than an all-metal valve. While suitable for many industrial processes, they are not intended for extremely high-temperature or high-pressure services where specialty metal alloys would be required.

Not Ideal for Abrasive Media

The primary strength of PTFE is its chemical resistance, not its hardness. It is a relatively soft material that can be damaged by abrasive slurries or fluids containing hard particulates, which can wear away the lining and compromise the valve's integrity.

Throttling vs. On/Off

While some designs can accommodate a partially open position for metered flow, ball valves are fundamentally designed for on/off service. Using them for continuous throttling or precision flow control can cause premature wear on the seats and is generally not recommended.

Making the Right Choice for Your Application

Selecting the correct valve comes down to matching its strengths to your primary operational goal.

- If your primary focus is handling highly corrosive liquids: The chemically inert PTFE lining provides the essential protection that standard metal valves cannot offer.

- If your primary focus is maintaining product purity: The non-reactive PTFE barrier is critical for preventing contamination in sensitive applications like food, beverage, and pharmaceuticals.

- If your primary focus is cost-effective, low-maintenance on/off control: The simple, no-lubrication design ensures a long and reliable service life in compatible chemical environments.

Ultimately, choosing a PTFE-lined ball valve is a strategic decision for safely and efficiently managing chemically aggressive or high-purity fluids.

Summary Table:

| Application | Primary Benefit | Ideal For |

|---|---|---|

| Chemical Processing | Superior corrosion resistance | Strong acids, alkalis, solvents |

| Pharmaceutical & Food | Maintains product purity, sterile | High-purity, contamination-free processes |

| Power Generation & Metallurgy | Durable on/off control | Handling aggressive treatment chemicals |

Need a reliable valve for corrosive or high-purity fluids?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including custom-lined ball valves, for the semiconductor, medical, laboratory, and industrial sectors. Our precision production and custom fabrication services—from prototypes to high-volume orders—ensure you get a valve that perfectly matches your application's chemical and purity requirements.

Contact us today to discuss your specific needs and get a solution that ensures safety, reliability, and longevity.

Visual Guide

Related Products

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What is the role of bearing pads in civil engineering? The Critical Interface for Structural Integrity

- What temperature range can PTFE gaskets and sheets withstand? A Guide from -200°C to +260°C

- What should be considered when selecting a CNC machining service for PTFE? Key Factors for Precision Parts

- What are the key benefits of PTFE (Teflon) gaskets? Superior Chemical & Temperature Resistance

- Why is PTFE packing preferred in the food and pharmaceutical industries? Ensure Purity and Compliance

- What is the typical lifespan of PTFE rotary shaft seals? Maximize Durability in Your Application

- What are the key properties of PTFE that make it suitable for bearing pads? Achieve Superior Load Management

- What are the processing methods for PTFE? A Guide to Compression Molding and Machining