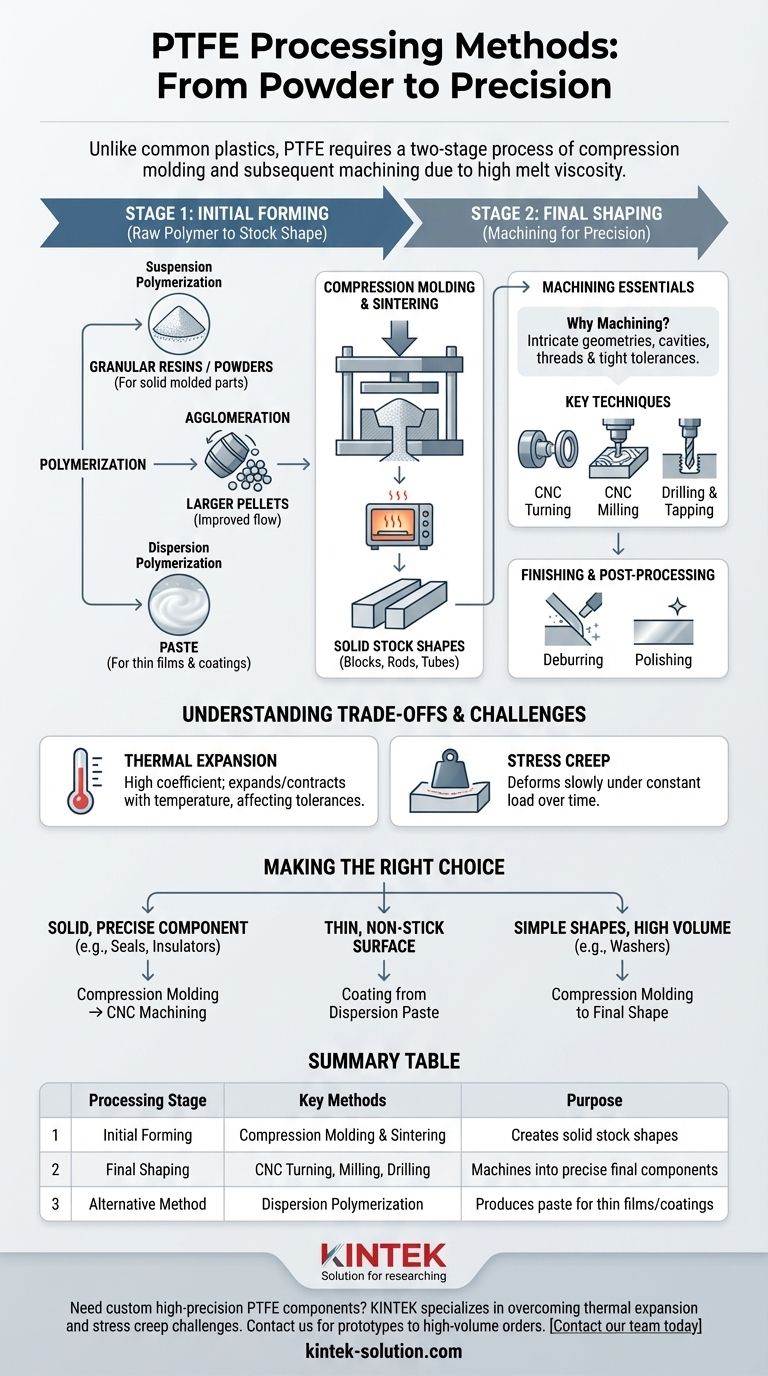

Unlike common plastics, Polytetrafluoroethylene (PTFE) has an extremely high melt viscosity, meaning it does not flow when heated. This property makes it impossible to process using conventional methods like injection molding. Instead, PTFE parts are primarily created through a two-stage process of compression molding and subsequent machining.

The core principle of PTFE processing is to first consolidate the raw powder into a solid, near-net "stock shape" through compression and heat, and then to refine that shape into a precise final component using standard machining techniques.

From Raw Polymer to Usable Form

Before a final part can be made, the raw PTFE material must be created and consolidated into a workable solid. This initial phase dictates the properties and potential applications of the material.

Suspension vs. Dispersion Polymerization

The journey begins with polymerization, and two methods produce distinct forms of raw PTFE. Suspension polymerization creates granular resins or fine powders, which are the basis for solid, molded parts.

In contrast, dispersion polymerization produces a milky, paste-like substance. This form is ideal for creating thin films and coatings, such as those used on non-stick cookware.

Preparing the Powder for Molding

The fine powder produced by suspension polymerization has poor flow properties, making it difficult to handle. To overcome this, it is processed into larger pellets through a process called agglomeration.

This involves tumbling the powder with a solvent, causing it to form into more uniform, free-flowing granules that are ideal for the molding process.

Compression Molding: Creating Stock Shapes

The most common method for forming solid PTFE is compression molding. The PTFE pellets are poured into a mold, compressed under high pressure, and then heated in an oven in a process called sintering.

This process fuses the PTFE particles into a solid, durable block, rod, or tube. These "stock shapes" are the raw material for the next stage of manufacturing.

Shaping the Final Part: Machining PTFE

Once a solid stock shape is created, it must be machined to achieve the final component's precise dimensions and features.

Why Machining is Essential

Because intricate geometries cannot be achieved through molding alone, machining is the go-to method for nearly all complex PTFE components. It allows for the creation of cavities, threads, and tight-tolerance features.

Key Machining Techniques

Standard CNC (Computer Numerical Control) equipment is used to shape PTFE. The most common techniques include:

- CNC Turning: Used to create cylindrical parts like rings, seals, shafts, and washers.

- CNC Milling: Used for more complex parts with intricate patterns, slots, and non-symmetrical features.

- Drilling and Tapping: Used to create precise holes and internal threads within a component.

Finishing and Post-Processing

After machining, parts may undergo post-processing steps. This includes deburring to remove any rough edges left by the cutting tools and polishing to achieve a smoother surface finish, ensuring the part meets all quality and performance standards.

Understanding the Trade-offs of Machining PTFE

While PTFE is soft and easy to cut, achieving precision can be challenging due to its unique material properties.

The Challenge of Thermal Expansion

PTFE has a very high coefficient of thermal expansion. This means it expands and contracts significantly with temperature changes. Heat generated during machining can cause the part to grow, making it difficult to hold tight tolerances.

The Problem of Stress Creep

PTFE is also susceptible to stress creep, which is the tendency of the material to slowly deform over time when under a constant load. This property must be accounted for in the initial design to prevent part failure in its final application.

Making the Right Choice for Your Application

Matching the processing method to your end goal is critical for a successful outcome.

- If your primary focus is creating a solid, precise component (e.g., an insulator, valve seat, or bushing): Your path is compression molding of a stock shape followed by CNC machining.

- If your primary focus is applying a thin, non-stick surface to another object: You will need a coating derived from PTFE dispersion paste.

- If your primary focus is producing very simple shapes in high volume (e.g., basic washers): Compression molding to the final shape may be a viable and cost-effective option.

Ultimately, successfully manufacturing a PTFE part depends on designing with its unique properties in mind, not against them.

Summary Table:

| Processing Stage | Key Methods | Purpose |

|---|---|---|

| Initial Forming | Compression Molding & Sintering | Creates solid stock shapes (blocks, rods, tubes) from PTFE powder. |

| Final Shaping | CNC Turning, Milling, Drilling | Machines stock shapes into precise, complex final components. |

| Alternative Method | Dispersion Polymerization | Produces paste for thin films and coatings, not solid parts. |

Need a custom PTFE component that meets your exact specifications?

At KINTEK, we specialize in manufacturing high-precision PTFE components—from seals and liners to complex labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in compression molding and precision CNC machining ensures your parts are designed to overcome PTFE's unique challenges, like thermal expansion and stress creep.

We handle everything from prototypes to high-volume orders. Contact our team today to discuss your project and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- Why did PTFE seals fall out of favor in the 1950s and 1960s? A Lesson in Material Misunderstanding

- How do PTFE seals contribute to reducing maintenance costs? Slash Costs with Superior Durability

- What are the advantages of using PTFE material for machine parts? Achieve Peak Performance in Demanding Environments

- What precautions should be taken when specifying PTFE Lip Seals? Ensure Long-Term Reliability for Your Application

- What is the temperature range that PTFE bushings can endure? Operate from -200°C to +260°C

- What are the key features of spiral PTFE backup rings? Superior Extrusion Protection for High-Pressure Seals

- What are the challenges of cleaning Teflon residue from a screw and barrel? A Guide to Safe, Effective Removal

- What are the achievable tolerances for Teflon parts? Master Precision Machining for PTFE