At its core, PTFE packing is the preferred choice in the food and pharmaceutical industries because its fundamental properties—being chemically inert, non-toxic, and non-contaminating—directly address the paramount need for product purity and safety. This material is not just a component; it is an integral part of maintaining the strict regulatory and hygiene standards that define these sectors.

The central challenge in food and pharmaceutical processing is preventing any interaction between equipment and the product itself. PTFE is the default solution because its inherent molecular stability ensures it will not react with, leach into, or contaminate sensitive products, making it a cornerstone of safe and compliant manufacturing.

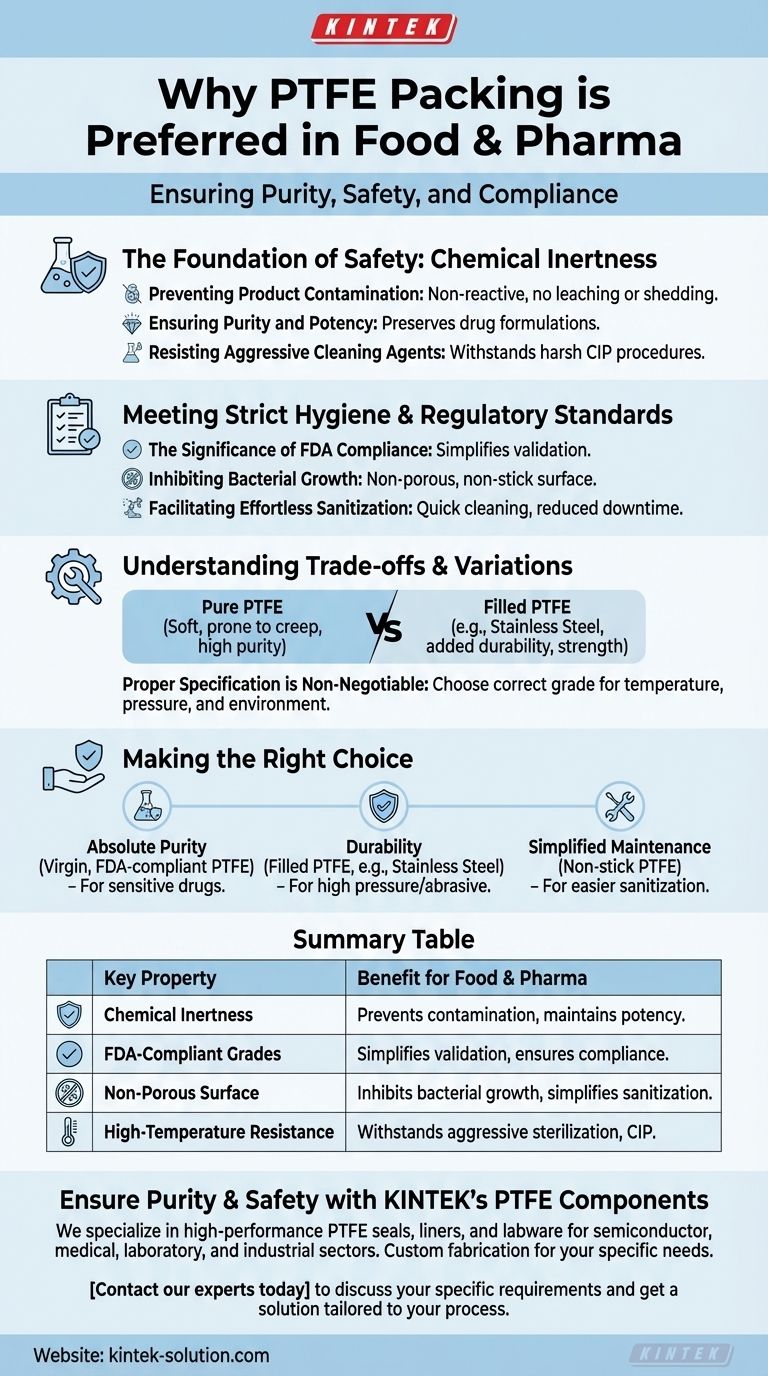

The Foundation of Safety: Chemical Inertness

The most critical attribute of PTFE (Polytetrafluoroethylene), widely known by the brand name Teflon, is its chemical inertness. This property is not an added feature but a result of its molecular structure.

Preventing Product Contamination

Because PTFE is exceptionally non-reactive, it does not leach chemicals or shed particles into the products it touches. This is essential for ensuring that foods, beverages, and active pharmaceutical ingredients (APIs) remain pure and unadulterated throughout the production process.

Ensuring Purity and Potency

In pharmaceuticals, even a minuscule reaction between a seal and a drug can alter the drug's chemical composition, compromising its efficacy and safety. PTFE's inertness guarantees that the material will not react with or absorb the product, preserving its intended formulation.

Resisting Aggressive Cleaning Agents

Food and pharmaceutical equipment must undergo rigorous sterilization and clean-in-place (CIP) procedures involving harsh chemicals and high temperatures. PTFE packing withstands these aggressive regimens without degrading, ensuring its integrity and preventing it from becoming a source of contamination itself.

Meeting Strict Hygiene and Regulatory Standards

Beyond its chemical properties, PTFE meets the operational and legal requirements of these highly regulated industries, providing a reliable path to compliance.

The Significance of FDA Compliance

PTFE is available in grades that are compliant with FDA regulations for food-contact materials. This approval simplifies the validation process for equipment, providing a clear and documented assurance that the material is safe for its intended use.

Inhibiting Bacterial Growth

The surface of PTFE is non-porous and exceptionally smooth. This non-stick characteristic prevents residues from adhering and denies bacteria a place to colonize, which is a critical factor in maintaining hygienic conditions.

Facilitating Effortless Sanitization

The famous non-stick quality of PTFE significantly simplifies cleaning. Equipment can be sanitized more quickly and effectively, reducing operational downtime and lowering the risk of cross-contamination between batches.

Understanding the Trade-offs and Variations

While PTFE is a superior material, it's important to understand its practical limitations and how they are addressed in real-world applications.

Mechanical Limitations of Pure PTFE

Virgin PTFE can be relatively soft and may be prone to "creep" or deform under high pressure or temperature. This can be a limitation in demanding mechanical applications.

The Role of Fillers for Enhanced Performance

To overcome these mechanical weaknesses, PTFE is often blended with fillers. For example, stainless steel-filled PTFE is used to add durability and strength, making it ideal for equipment that requires both the inertness of PTFE and greater structural rigidity.

Proper Specification is Non-Negotiable

The effectiveness of PTFE packing depends entirely on choosing the correct grade and design for the specific application's temperature, pressure, and chemical environment. An incorrect specification can lead to premature failure, negating the material's benefits.

Making the Right Choice for Your Application

Selecting the right material is a critical decision based on your primary operational goal.

- If your primary focus is absolute product purity for sensitive drugs: Insist on using virgin, FDA-compliant PTFE to guarantee zero reactivity and avoid any potential contaminants from fillers.

- If your primary focus is durability in high-pressure or abrasive processing: Consider a filled PTFE, such as stainless steel or glass-filled variants, to gain the necessary mechanical strength while retaining chemical resistance.

- If your primary focus is simplifying maintenance and reducing cleaning time: Leverage the inherent non-stick properties of PTFE to design systems that are easier to sanitize, thereby increasing operational efficiency.

Ultimately, selecting PTFE is a strategic decision to build safety, hygiene, and regulatory compliance directly into the foundation of your process equipment.

Summary Table:

| Key Property | Benefit for Food & Pharma |

|---|---|

| Chemical Inertness | Prevents product contamination and maintains potency. |

| FDA-Compliant Grades | Simplifies validation and ensures regulatory compliance. |

| Non-Porous Surface | Inhibits bacterial growth and simplifies sanitization. |

| High-Temperature Resistance | Withstands aggressive sterilization and CIP processes. |

Ensure the purity and safety of your products with precision-engineered PTFE components from KINTEK.

We specialize in manufacturing high-performance PTFE seals, liners, and labware for the semiconductor, medical, laboratory, and industrial sectors. Whether you require the absolute purity of virgin PTFE for sensitive pharmaceuticals or the enhanced durability of filled PTFE for demanding applications, our custom fabrication services—from prototypes to high-volume orders—deliver the reliability you need.

Contact our experts today to discuss your specific requirements and get a solution tailored to your process.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry

- How is PTFE used in industrial processes? Maximize Safety and Efficiency

- When and by whom was PTFE discovered? A Tale of Accidental Innovation